Method for preparing fibrilia carboxylation cellulose nanowhiskers

A technology of carboxylated cellulose and nanocrystals, applied in the direction of nanotechnology, can solve the problems of high crystallinity of hemp fibers, difficult cellulose nanocrystals, etc., and achieve the effects of good repeatability, simple preparation process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

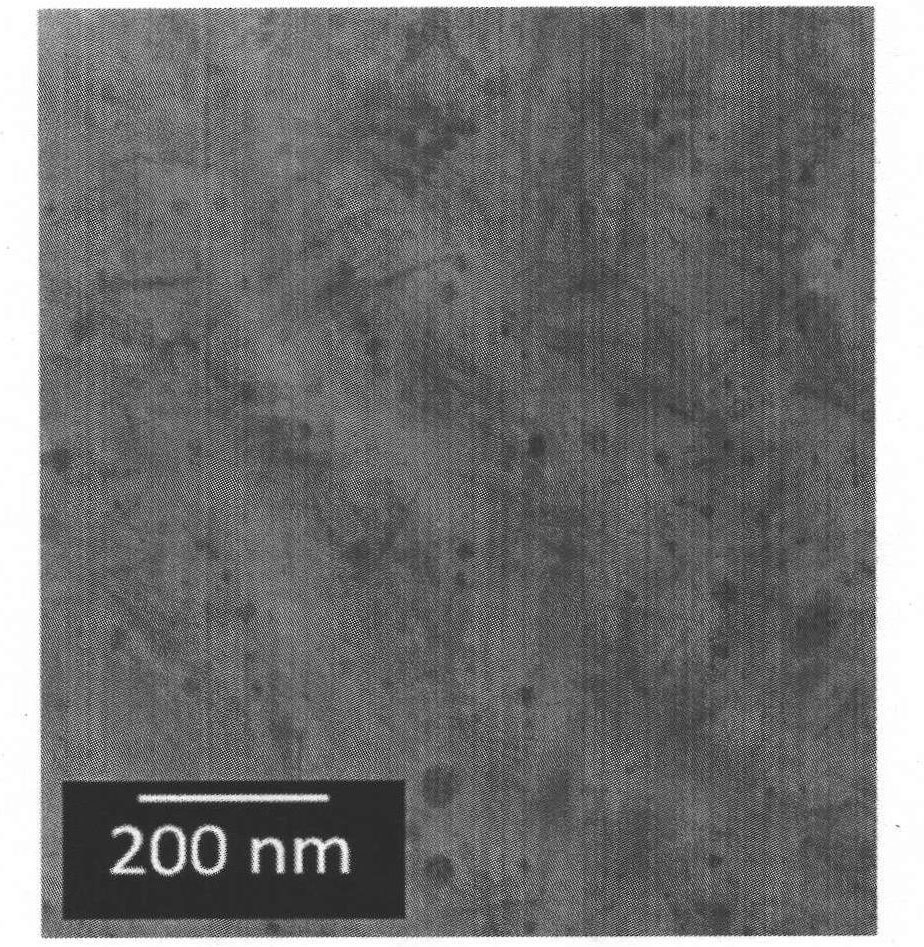

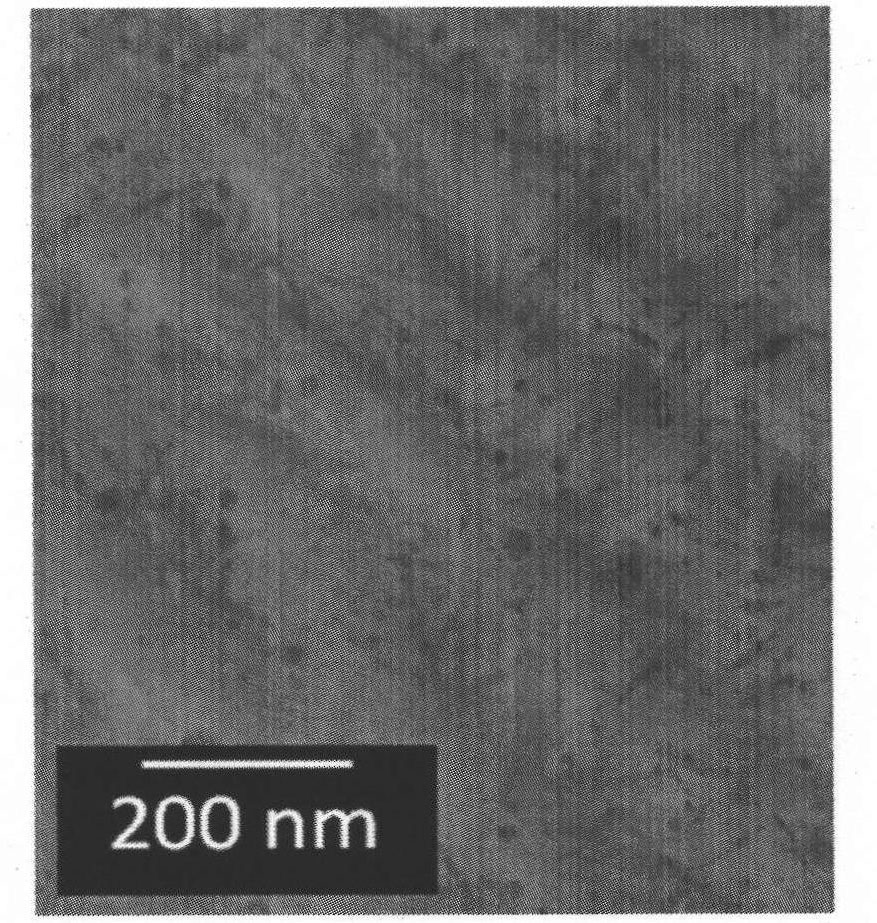

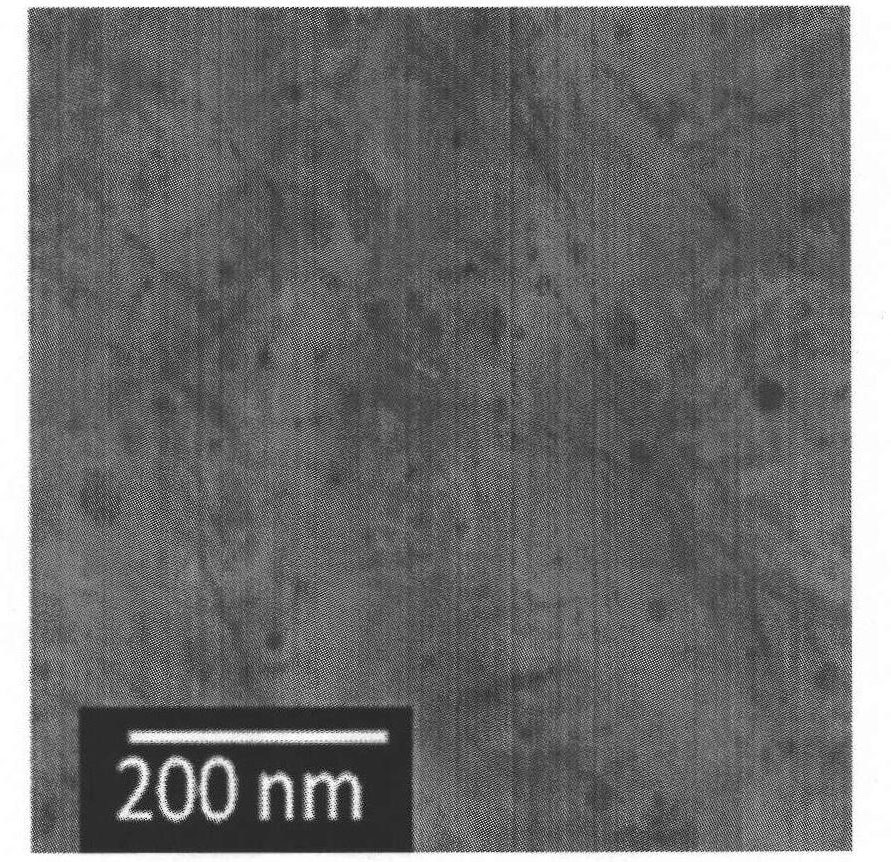

Image

Examples

Embodiment 1

[0032] (1) Under the temperature condition of 20 ℃ of water baths, 1.0g60 purpose jute fiber powder is soaked in the stirred kettle that fills 50g mass fraction and is 15% sodium hydroxide solution, stirs 120min with the stirring speed of 300rpm, then pumps out with vacuum pump Filter, wash the jute fiber powder of gained to neutrality, dry in vacuum oven, vacuum tightness is 0.1MPa, and drying temperature is 60 ℃, and drying time is 12h, obtains the jute fiber powder of alkali treatment;

[0033] (2) under the temperature condition of 70 ℃ of water baths, the jute fiber powder of alkali treatment that the first step obtains is joined in the stirred tank that fills dimethyl sulfoxide (DMSO), the jute fiber powder of alkali treatment and dimethyl The solid-to-liquid mass ratio of sulfoxide was 1:50, stirred for 4h at a stirring speed of 500rpm, filtered, and the residual dimethyl sulfoxide was eluted with distilled water, and the jute fiber powder was dried in a vacuum oven with...

Embodiment 2

[0038] (1) Under the temperature condition of 80 ℃ of water baths, 20g60 purpose flax fiber powders are soaked in the mass fraction that fills 200g and be 20% sodium hydroxide solution stirring tank, stir 100min with the stirring speed of 300rpm, then use vacuum pump suction filtration, The flax fiber powder obtained was washed to neutrality, and dried in a vacuum oven with a vacuum degree of 0.1 MPa, a drying temperature of 80° C., and a drying time of 6 hours to obtain alkali-treated flax fiber powder;

[0039] (2) Under the temperature condition of 70 ℃ of water baths, the flax fiber powder of alkali treatment that the first step obtains is joined in the stirred tank that fills the tetrabutylammonium bromide solution of 10% by mass fraction, the flax fiber powder of alkali treatment The solid-liquid mass ratio of powder and tetrabutylammonium bromide solution is 1: 20, stirs 6h with the stirring speed of 100rpm, suction filtration, with distilled water eluting residual tetra...

Embodiment 3

[0044] (1) under 60 ℃ of water-bath temperature conditions, 1g60 purpose jute fiber powder is soaked in the mass fraction that fills 40g and is in the stirred tank of 16% sodium hydroxide solution, stirs 300min with the stirring speed of 200rpm, then uses vacuum pump suction filtration, The jute fiber powder of gained is washed to neutrality, is dried in vacuum oven, and vacuum degree is 0.1MPa, and drying temperature is 70 ℃, and drying time is 12h, obtains the jute fiber powder of alkali treatment;

[0045] (2) under 70 ℃ of water-bath temperature conditions, the jute fiber powder of the alkali treatment that the first step obtains joins in the stirred tank that fills the massfraction of 30% methyl trioctyl ammonium chloride solution, the alkali treatment The solid-liquid mass ratio of jute fiber powder and methyl trioctyl ammonium chloride solution is 1: 20, stirs 4h with the stirring speed of 300rpm, suction filtration, residual methyl trioctyl ammonium chloride is washed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com