Antibacterial warp knitted lace fabric and preparation method thereof

A warp knitting and lace technology, applied in the fields of botanical equipment and methods, warp knitting, fungicides, etc., can solve the problems of complex fabric technology, achieve excellent antibacterial properties, maintain antibacterial properties, improve application prospects and added value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A kind of antibacterial warp-knitted lace fabric and preparation method thereof, the weight of antibacterial warp-knitted lace fabric is 100g / m 2 , the bursting strength is 1000N, and the antibacterial rate against Staphylococcus aureus and Escherichia coli is greater than 90%.

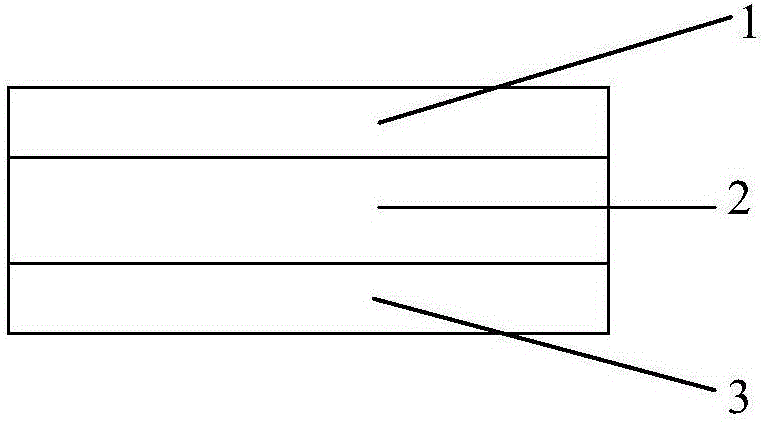

[0089] Please see attached figure 1 , the antibacterial warp-knitted lace fabric has a three-layer structure, followed by an antibacterial surface layer, a middle layer and an antibacterial bottom layer, the antibacterial surface layer and the middle layer are woven by a three-dimensional warp knitting process, and the antibacterial bottom layer and the middle are formed by a three-dimensional warp knitting process , the antibacterial warp knitted lace fabric is obtained through the warp knitting process.

[0090] The thickness of the antibacterial surface layer is 100 microns, the thickness of the middle layer is 200 microns, and the thickness of the antibacterial bottom layer is 100 microns....

Embodiment 2

[0116] A kind of antibacterial warp-knitted lace fabric and preparation method thereof, the weight of antibacterial warp-knitted lace fabric is 600g / m 2 , the bursting strength is 4500N, and the antibacterial rate against Staphylococcus aureus and Escherichia coli is greater than 90%.

[0117] Please see attached figure 1 , the antibacterial warp-knitted lace fabric has a three-layer structure, followed by an antibacterial surface layer, a middle layer and an antibacterial bottom layer, the antibacterial surface layer and the middle layer are woven by a three-dimensional warp knitting process, and the antibacterial bottom layer and the middle are formed by a three-dimensional warp knitting process , the antibacterial warp knitted lace fabric is obtained through the warp knitting process.

[0118] The thickness of the antibacterial surface layer is 500 microns, the thickness of the middle layer is 800 microns, and the thickness of the antibacterial bottom layer is 500 microns....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com