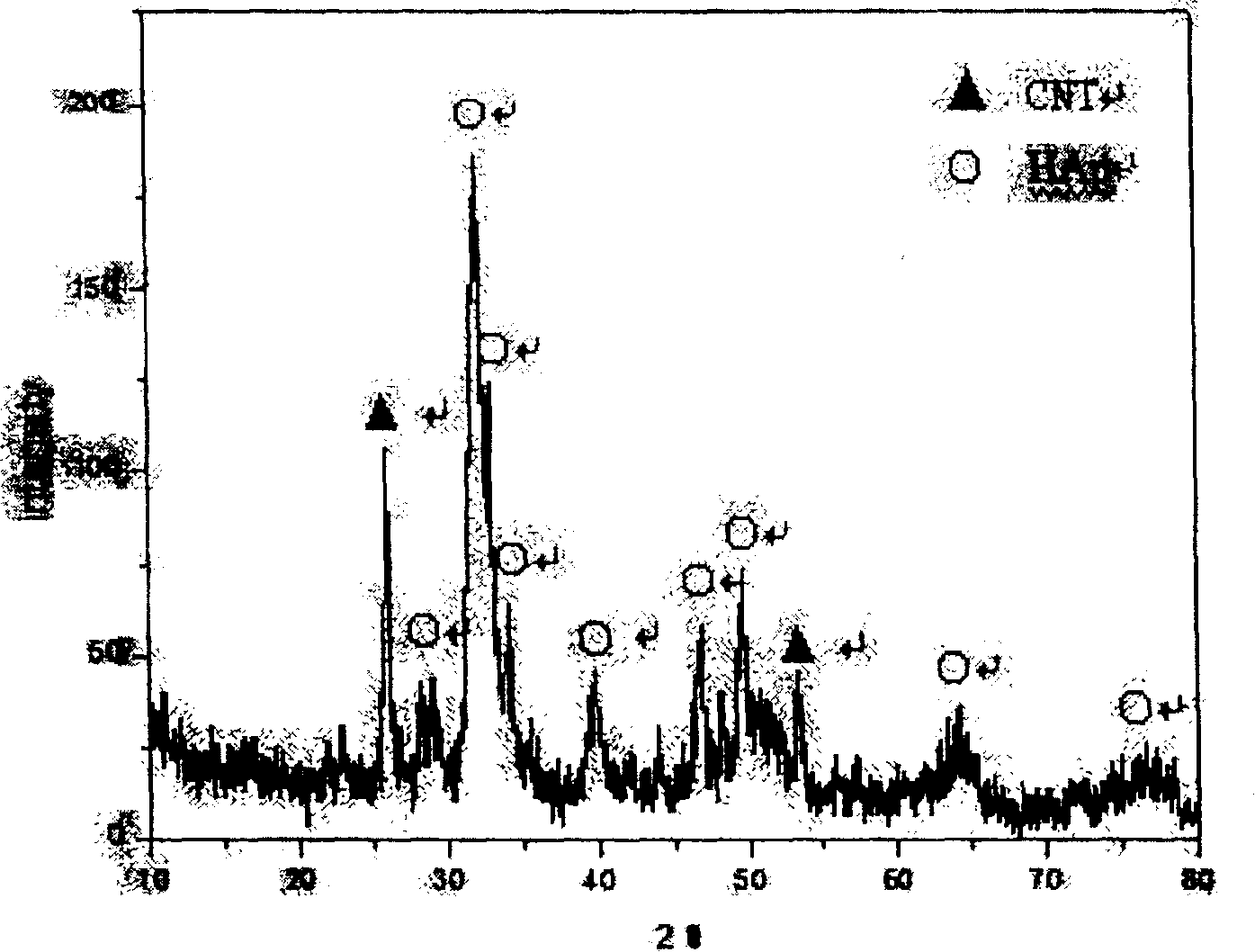

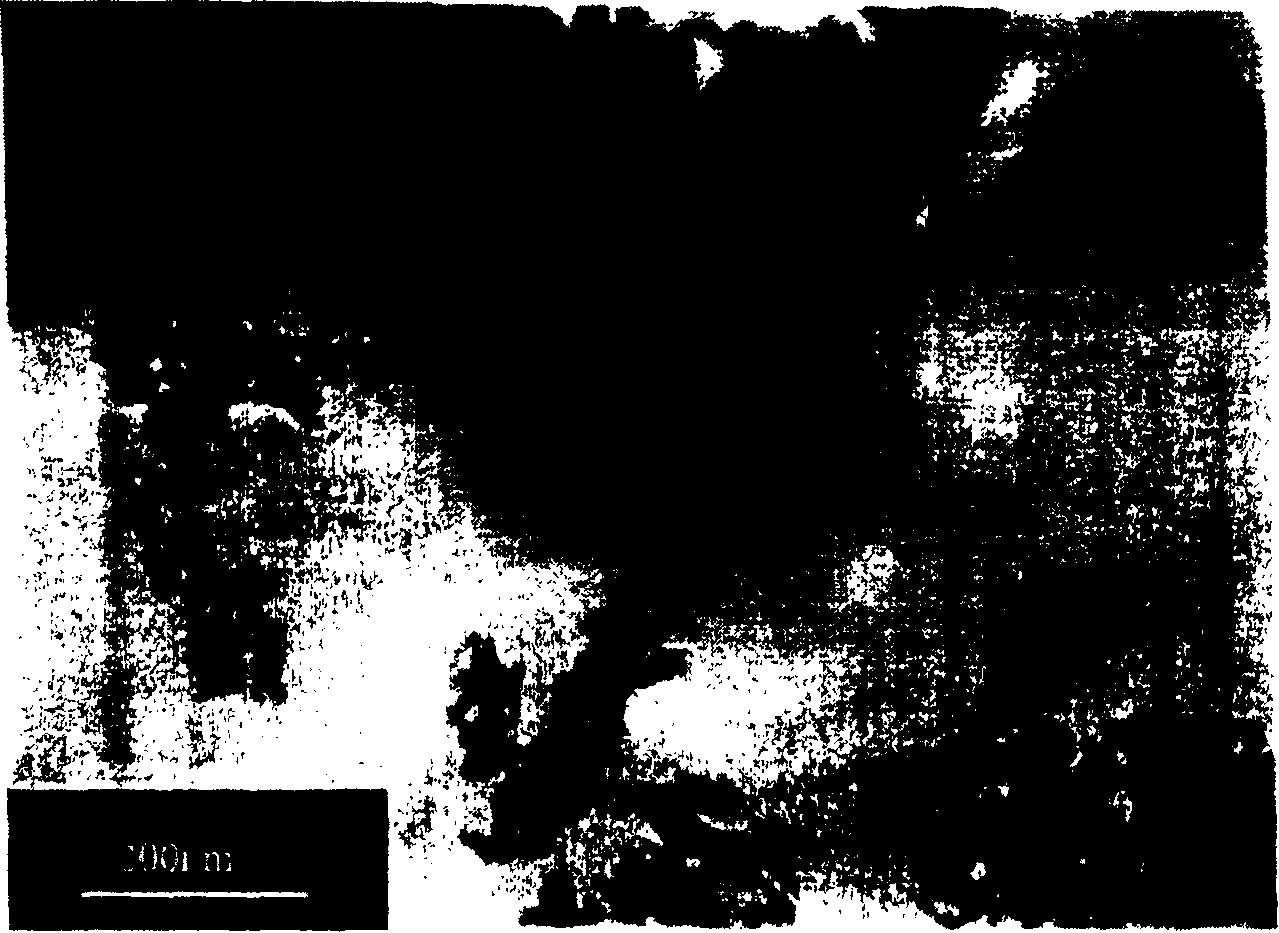

Method for cladding Nano carbon tube by using hydroxyapatite

A technology of hydroxyapatite and carbon nanotubes, which is applied in the preparation of carbon nanotubes. The field of coating carbon nanotubes with hydroxyapatite can solve problems such as deposition and health hazards, and achieve improved mechanical properties, reduced toxicity, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) reflux treatment of multi-walled carbon nanotubes in concentrated nitric acid with a concentration of 70% at 120° C. for 4 hours, then wash with distilled water until neutral, dry, grind, and pass through a 300-mesh sieve for later use;

[0037] 2) taking the anionic surfactant sodium dodecylsulfonate as a dispersant, distilled water as a dispersion medium, and making a 1% sodium dodecylsulfonate solution by mass percentage, the carbon nanotubes prepared in step 1) Add it, ultrasonically disperse for 2 hours, and prepare a suspension with a concentration of 0.6g / L;

[0038] 3) Ca(NO 3 ) 2 with (NH 4 ) 2 HPO 4 Prepare a calcium ion solution with a concentration of 1.2mol / L and a phosphorus ion solution with a concentration of 0.72mol / L;

[0039] 4) Ca(NO) prepared in step 3) 3 ) 2 The solution is slowly added to the suspension described in step 2), the pH value is adjusted to 10 with ammonia water, and then ultrasonically dispersed for 0.5 hours, and then trans...

Embodiment 2

[0043] 1) Treat the multi-walled carbon nanotubes prepared by the catalytic cracking method in sulfuric acid with a concentration of 98.3% at 100° C. for 1 hour, then wash with distilled water until neutral, dry, grind, and pass through a 300-mesh sieve for later use ;

[0044] 2) take anionic surfactant sodium dodecylbenzene sulfonate as dispersant, distilled water is dispersion medium, be made into the sodium dodecylbenzenesulfonate solution that mass percent is 1%, the carbon that step 1) makes Add nanotubes to it, ultrasonically disperse for 3 hours, and prepare a suspension with a concentration of 1g / L;

[0045] 3) Ca(NO 3 ) 2 with (NH 4 ) 2 HPO 4 Prepare a calcium ion solution with a concentration of 1.2mol / L and a phosphorus ion solution with a concentration of 0.72mol / L;

[0046] 4) Ca(NO) prepared in step 3) 3 ) 2 The solution is slowly added to the suspension described in step 2), the pH value is adjusted to 13 with ammonia water, and then ultrasonically disp...

Embodiment 3

[0049] 1) The multi-walled carbon nanotubes prepared by laser evaporation method were dissolved in the mixture of concentrated nitric acid and concentrated sulfuric acid (V 硫酸 / V 硝酸 =3:1), reflux at 140°C for 6 hours, then wash with distilled water until neutral, dry, grind, and pass through a 300-mesh sieve for later use;

[0050] 2) Using the anionic surfactant citric acid as a dispersant and distilled water as a dispersion medium, prepare a citric acid solution with a mass percentage of 2%, add the carbon nanotubes prepared in step 1) to it, ultrasonically disperse for 0.5 hours, and prepare into a suspension with a concentration of 0.3g / L;

[0051] 3) Ca(NO 3 ) 2 with (NH 4 ) 2 HPO 4 Prepare a calcium ion solution with a concentration of 1.2mol / L and a phosphorus ion solution with a concentration of 0.72mol / L;

[0052] 4) Ca(NO) prepared in step 3) 3 ) 2 The solution is slowly added to the suspension described in step 2), the pH value is adjusted to 11 with ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com