Preparation method of magnetic cellulose nanocrystal

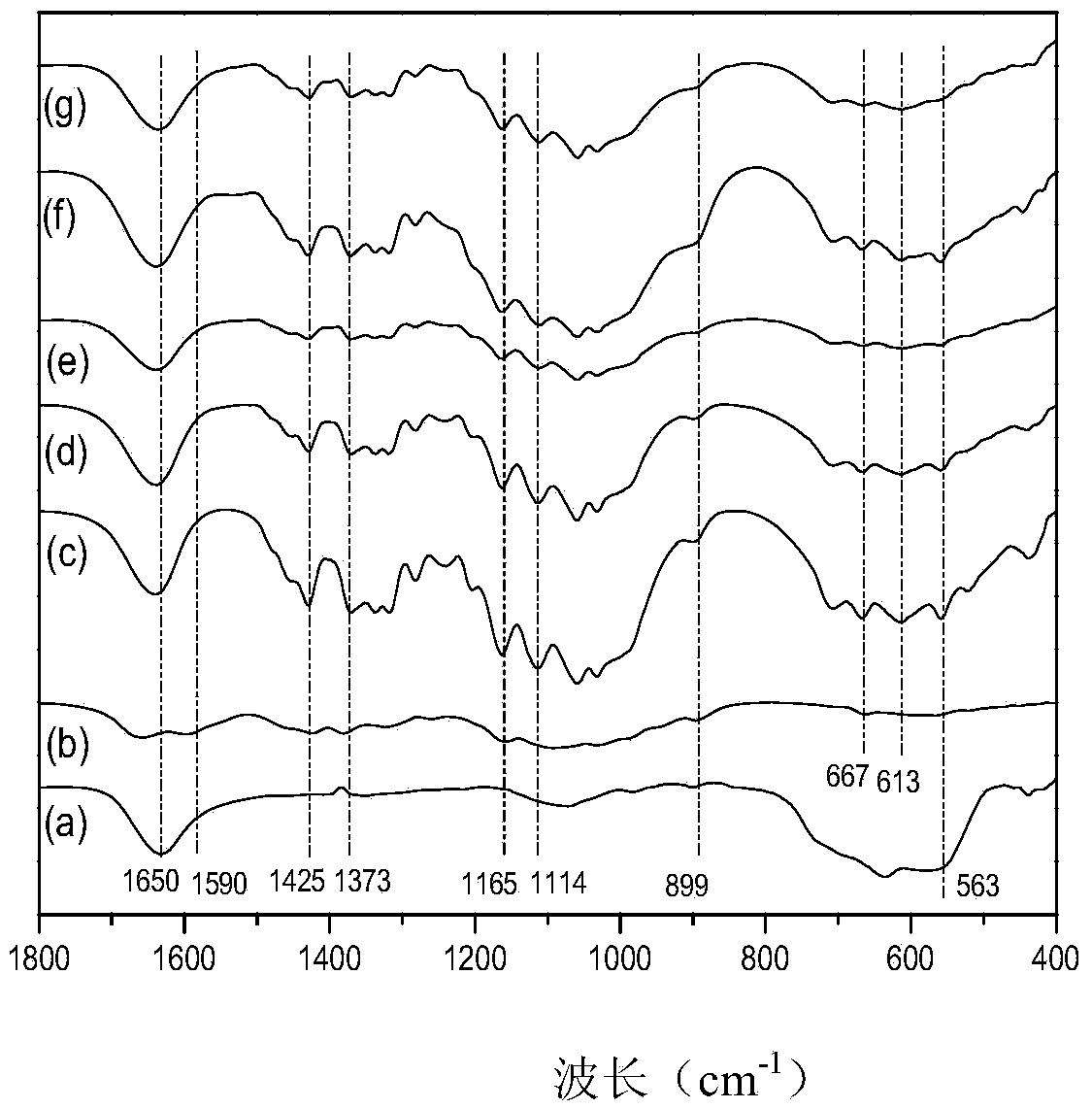

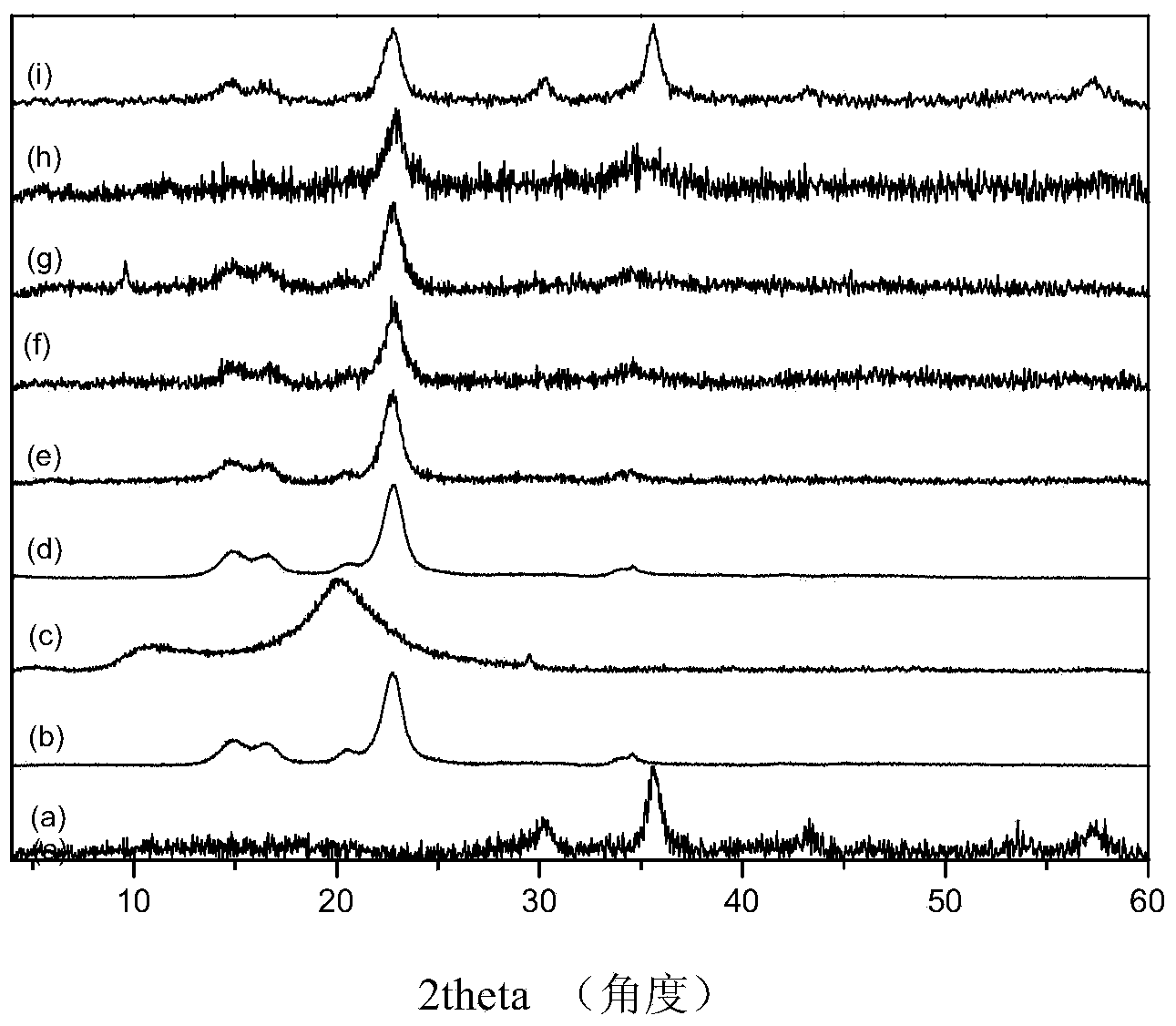

A technology of cellulose and nanocrystals, applied in the field of cellulose, can solve the problems of uneven distribution, incomplete combination of magnetic nanoparticles and cellulose materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

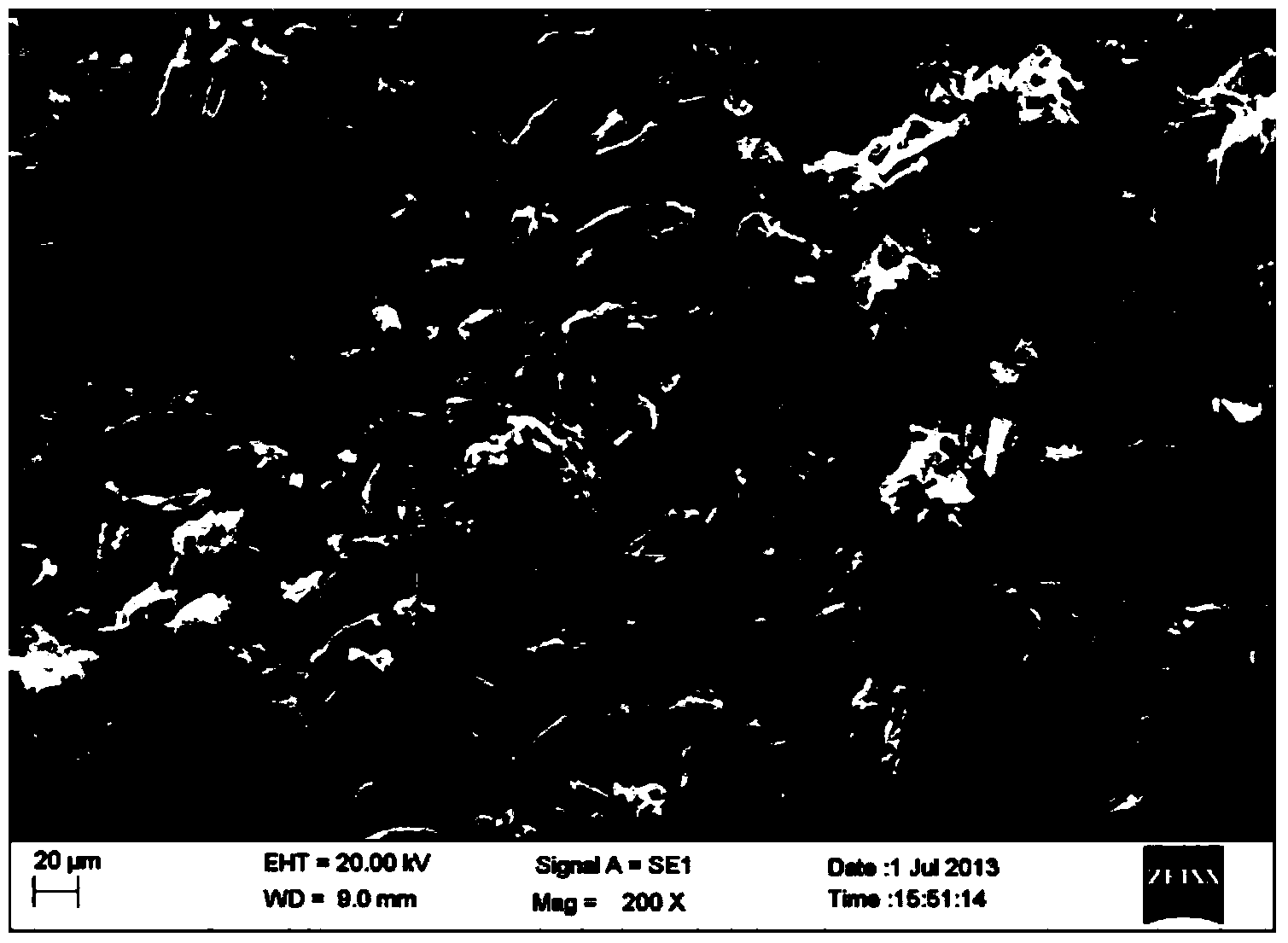

[0026] Add microcrystalline cellulose to 6mol / L hydrochloric acid solution, wherein the solid-to-liquid ratio of microcrystalline cellulose to acid solution is 1:25g / mL, and the mixed solution is reacted at 80°C, the stirring rate is 1000r / min, and the reaction is 90min. After the end, move the reactant into a centrifuge tube, centrifuge at 4000r / min for 5min, pour off the supernatant, and then add deionized water, wherein the volume of deionized water is the same as that of the hydrochloric acid solution added before, and then centrifuge at 4000r / min Centrifuge for 5 minutes to obtain a crude product of cellulose nanocrystals. The morphology of the nanocrystalline crude product after freeze-drying is image 3 shown.

[0027] Get 6.6g cellulose nanocrystal thick product, add 200ml iron ion concentration and be 0.09455mol / L solution, wherein Fe 3+ Accounting for 64.21% of the total moles of iron ions, Fe 2+ accounted for 35.79%, stirring at a rate of 1000r / min for 10min, the...

Embodiment 2

[0030] Add cotton to 6mol / L hydrochloric acid solution (different examples try to use different acid solutions), wherein the solid-to-liquid ratio of microcrystalline cellulose to hydrochloric acid solution is 1g:25mL, and the mixed solution reacts with 100°C and the stirring rate is 2000r / min , after the reaction is over, move the reactant into a centrifuge tube, centrifuge at 4000r / min for 5min, pour off the supernatant, and then add deionized water, wherein the deionized water is twice the volume of the acid solution added before, and then in Centrifuge at 4000r / min for 5min to obtain a crude product of cellulose nanocrystals.

[0031] Get 6.6g cellulose nanocrystal thick product, add 200ml iron ion concentration and be 0.1891mol / L solution, wherein Fe 3+ Accounting for 50% of the total moles of iron ions, Fe 2+ accounted for 50%, stirring at a stirring rate of 5000r / min for 10min, then adding 30ml of a chitosan solution with a mass concentration of 2%, stirring for 50min ...

Embodiment 3

[0033] Add bacterial cellulose to 6mol / L hydrochloric acid solution, wherein the solid-to-liquid ratio of microcrystalline cellulose and acid solution is 1:25g / mL, the mixed solution is reacted at 80°C, and the stirring rate is 1000r / min. After the reaction is completed, the The reactant was transferred into a centrifuge tube, centrifuged at 4000r / min for 5min, poured off the supernatant, and then added deionized water, wherein the volume of deionized water was the same as that of the acid solution added before, and then centrifuged at 4000r / min for 5min to obtain Cellulose nanocrystalline crude product. Get 6.6g cellulose nanocrystal thick product, add 200ml iron ion concentration and be 0.1891mol / L solution, wherein Fe 3+The ratio to the total number of moles of iron ions is 55, Fe 2+ Accounting for 45%, after stirring for 10 minutes, add 30ml of 4% chitosan solution, stirring at a rate of 1000r / min, and stirring for 50min. Then add 20ml of 12% sodium tripolyphosphate aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com