Packaging method of lithium ion battery, and lithium ion battery

A lithium-ion battery and packaging method technology, which is applied to secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the waste of aluminum-plastic film materials, defective products with scratches, and poor liquid absorption capacity of battery cells. problems, to achieve the effect of reducing material waste, ensuring filling and injecting liquid, and quickly infiltrating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

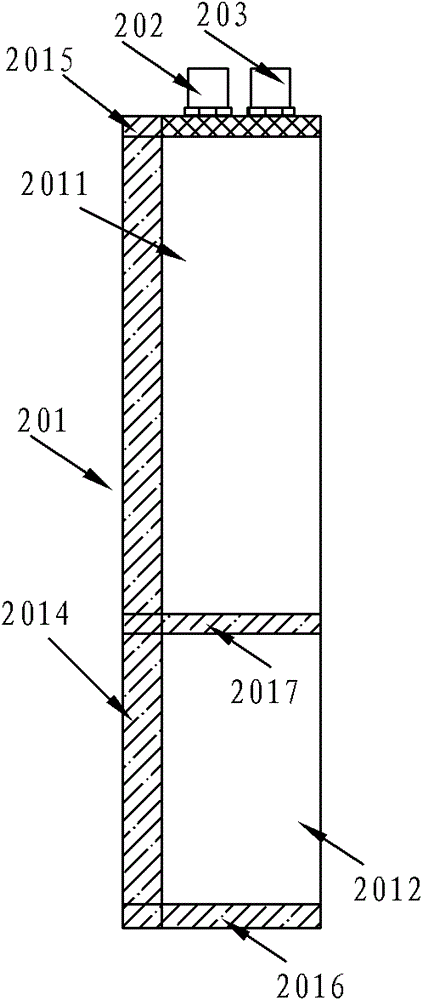

[0051] See figure 2 .

[0052] This embodiment provides a lithium ion battery, which includes the following main components: battery core body (not shown in the figure), aluminum-plastic film casing 201, electrolyte (not shown in the figure), positive pole ear 202 and negative pole Ear 203. Its connection relationship is as follows:

[0053] In the aluminum-plastic film casing 201 of this embodiment, two independent and non-communicating cavities are formed: the cell cavity 2011 and the airbag cavity 2012 .

[0054] Wherein, the cell cavity 2011 is completely sealed, and the electrolyte, and the cell body including the positive electrode sheet, the negative electrode sheet and the diaphragm are sealed and packaged in the cell cavity 2011 .

[0055] An air hole is provided on the surface of the airbag cavity 2012 (not shown in the figure, it is an insertion hole formed by a vacuum suction tube formed during the secondary sealing of the vacuum). The airbag cavity 2012 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com