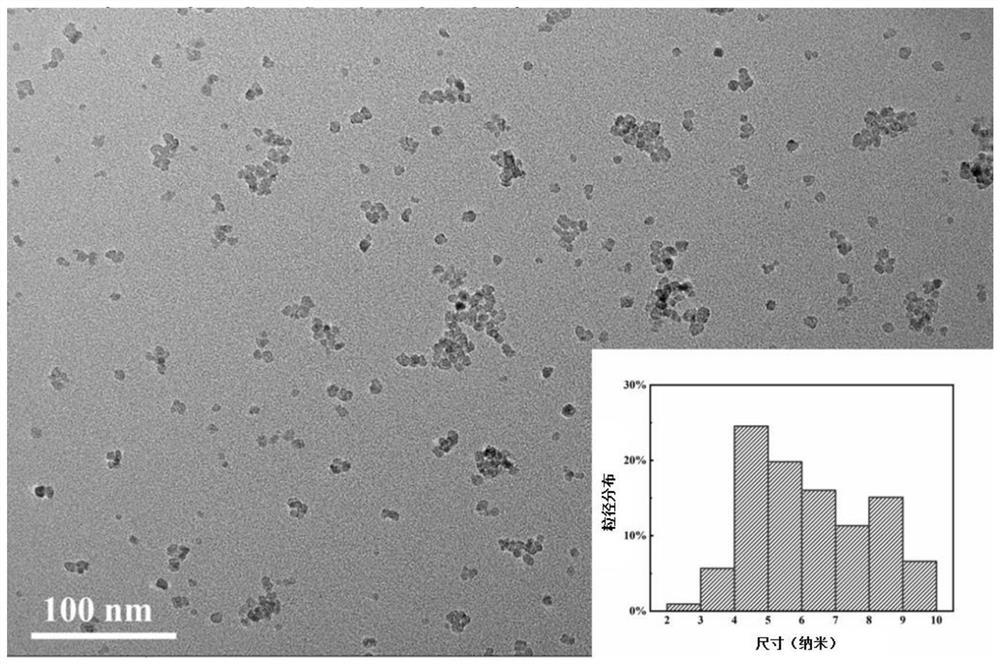

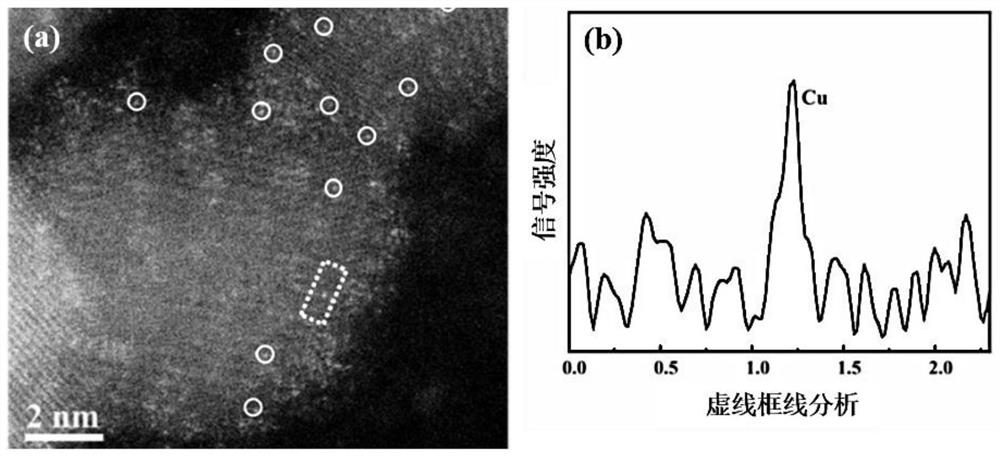

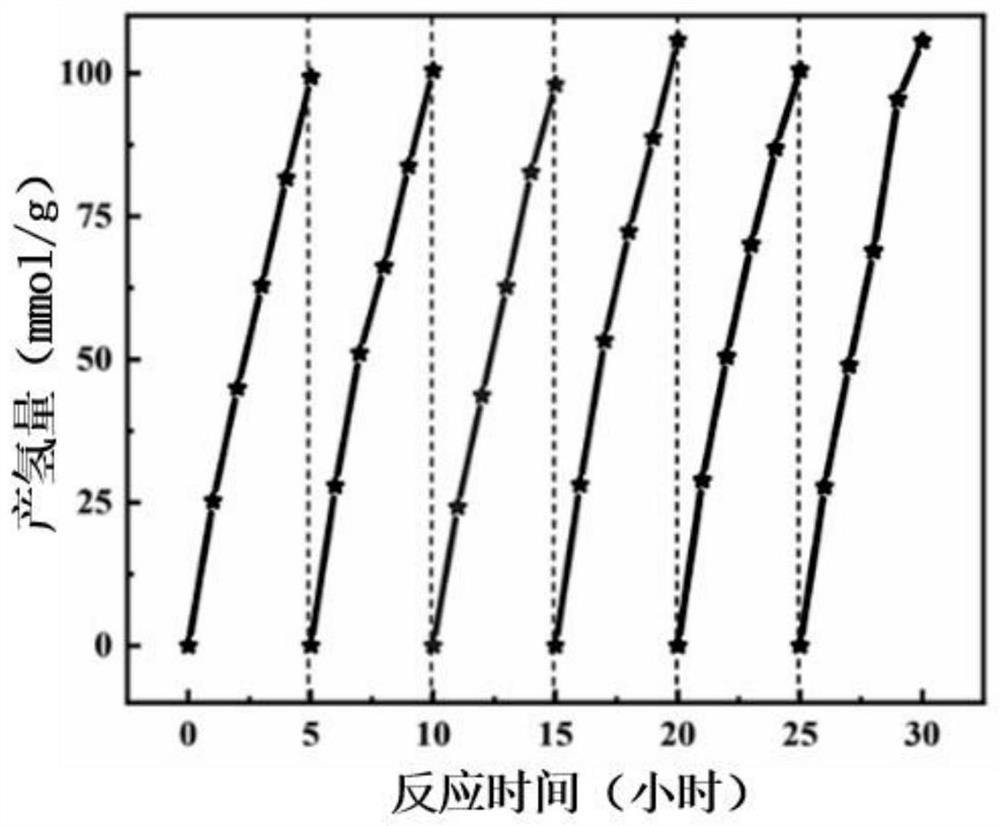

Monoatomic loaded TiO2 quantum dot photocatalyst and preparation method thereof

A photocatalyst and quantum dot technology, applied in the chemical industry, can solve the problems of increased difficulty and cost of synthesis, high surface exposure rate of single atoms, difficulty in controlling synthesis conditions, etc., to achieve increased single atom exposure rate, increased effective active sites, The effect of good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Proportionally add 10mL tetrabutyl titanate to 160mL ethanol, then add 10mL hydrolysis inhibitor (8mL triethanolamine + 2mL 10% acetic acid) and 59mg ferric nitrate nonahydrate, react at 150°C for 50 hours, centrifuge and wash, that is Obtaining highly dispersed and large specific surface area TiO supported by iron single atoms 2 Quantum dot photocatalyst (the molar ratio of titanium and iron is 99.5:0.5).

Embodiment 2

[0031] Proportionally add 10mL tetrabutyl titanate to 160mL ethanol, then add 12mL hydrolysis inhibitor (8mL triethanolamine + 4mL 10% acetic acid) and 118mg ferric nitrate nonahydrate, react at 150°C for 60 hours, centrifuge and wash, that is Obtaining highly dispersed and large specific surface area TiO supported by iron single atoms 2 Quantum dot photocatalyst (the molar ratio of titanium and iron is 99:1).

Embodiment 3

[0033] Proportionally add 10mL tetrabutyl titanate to 160mL ethanol, then add 15mL hydrolysis inhibitor (10mL acetylacetone + 5mL 2% hydrochloric acid) and 94mg lanthanum nitrate hexahydrate, react at 120°C for 70 hours, centrifuge and wash, that is Obtaining highly dispersed and large specific surface area TiO supported by lanthanum single atom 2 Quantum dot photocatalyst (the molar ratio of titanium and lanthanum is 99.25:0.75).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com