A kind of preparation method of surface functionalized cellulose nanospheres

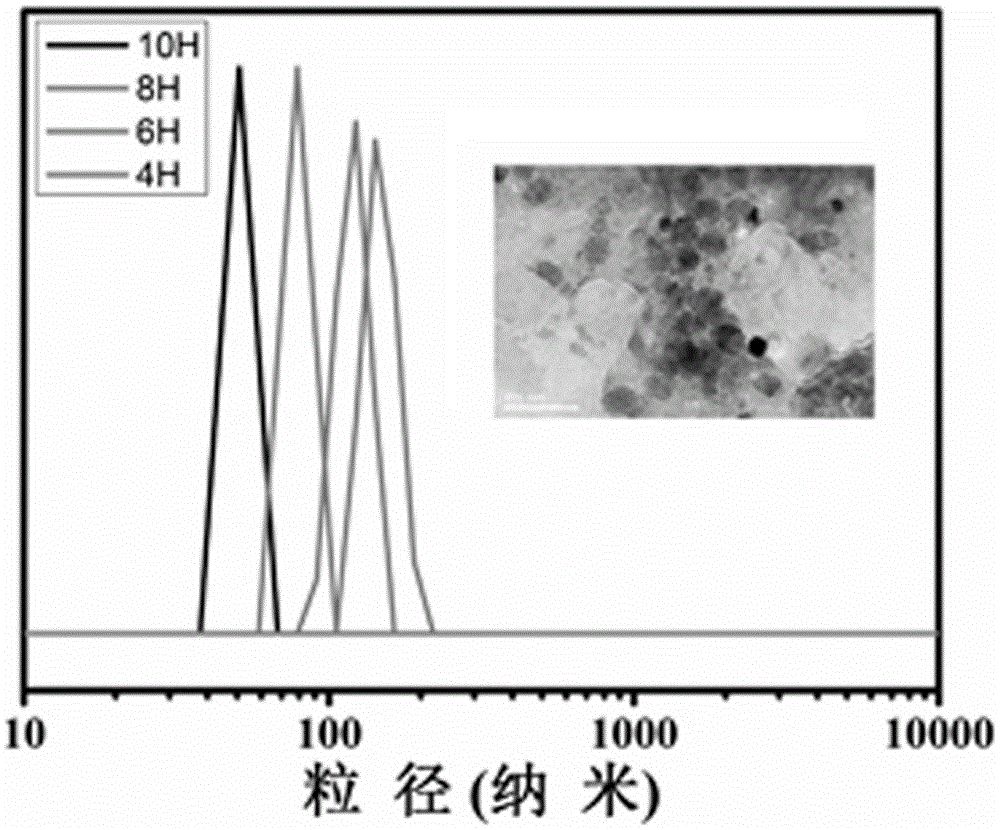

A surface functionalization and cellulose technology, which is applied in the field of preparation of cellulose nanocrystals, can solve the problems of insufficient uniformity of the size of cellulose nanospheres, long reaction time of enzymatic hydrolysis, reduced thermal stability, etc. Mild conditions and easy control, narrow distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add the microcrystalline cellulose fiber to the calcium hydroxide solution with a concentration of 1mol / L, and swell at room temperature for 4 hours, wherein the mass-volume ratio of the fiber to the lye is 0.02g / mL, filter the above mixed solution, and wash the product several times with water. until PH=7, at 50 o C to dry to constant weight; then the above product is added to the mixed acid solution obtained by mixing hydrochloric acid and formic acid with a concentration of 2mol / L and a ratio of 1:9 to fully infiltrate, wherein the mass volume ratio of fiber to acid solution is 0.008g / mL, put the above solution into the reaction vessel, at 65 o C, reacted for 6 hours under stirring with a tetrafluoroethylene stirring paddle, after the above reaction product was cooled naturally, added 2mol / L ammonia solution, adjusted the pH value of the solution to 7, and obtained a uniformly distributed cellulose nanosphere dispersion, and then After centrifuging and washing the ...

Embodiment 2

[0023] Add the lyocell fibers to a sodium hydroxide solution with a concentration of 2 mol / L, and swell at room temperature for 6 hours, wherein the mass-volume ratio of the fibers to the alkali solution is 0.1 g / mL, filter the above mixed solution, and wash the product with water for several times until the pH = 7 at 75 oC and dried to constant weight; then the above product was added to the mixed acid solution obtained by mixing hydrochloric acid and formic acid with a concentration of 5 mol / L in a ratio of 1:9, and the mass volume ratio of the fiber to the acid solution was 0.016g / mL, put the above solution into the reaction vessel, at 75 o C, reacted for 8 hours under stirring with a tetrafluoroethylene stirring paddle, after the above-mentioned reaction product was naturally cooled, 3mol / L hydrazine hydrate was added, and the pH value of the solution was adjusted to 7 to obtain a uniformly distributed cellulose nanosphere dispersion, and then After centrifuging and wash...

Embodiment 3

[0025] Add the waste cotton fiber to the barium hydroxide solution with a concentration of 1mol / L, and swell for 4 hours at room temperature, wherein the mass-volume ratio of the fiber to the lye is 0.04g / mL, filter the above mixed solution, and wash the product with water for several times until the pH =7 at 65 o C and dried to constant weight; then the above product was added to the mixed acid solution obtained by mixing hydrochloric acid and acetic acid with a concentration of 7mol / L and a ratio of 1:9 to fully infiltrate, wherein the mass volume ratio of fiber to acid solution was 0.012g / mL, put the above solution into the reaction vessel, at 70 o C, reacted for 7 hours under stirring with a tetrafluoroethylene stirring paddle, after the above reaction product was naturally cooled, add 1mol / L sodium hydroxide solution, adjust the pH value of the solution to 7, and obtain a uniformly distributed cellulose nanosphere dispersion , and then the dispersion liquid was centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com