Method and grinding machine for measuring and producing a target outer contour of a workpiece by means of grinding

A grinding machine and workpiece technology, which is applied to machine tools designed for grinding the rotating surface of workpieces, parts of grinding machine tools, and control of workpiece feed motion, etc. Grinding in a spherical or concave shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

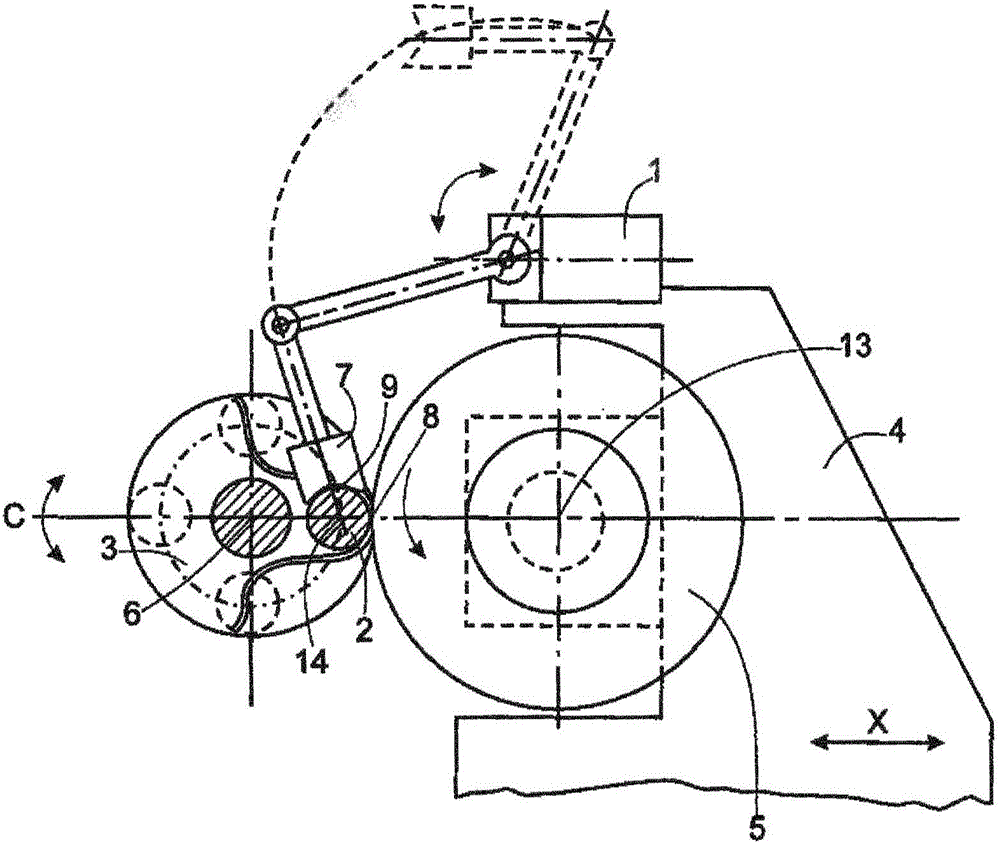

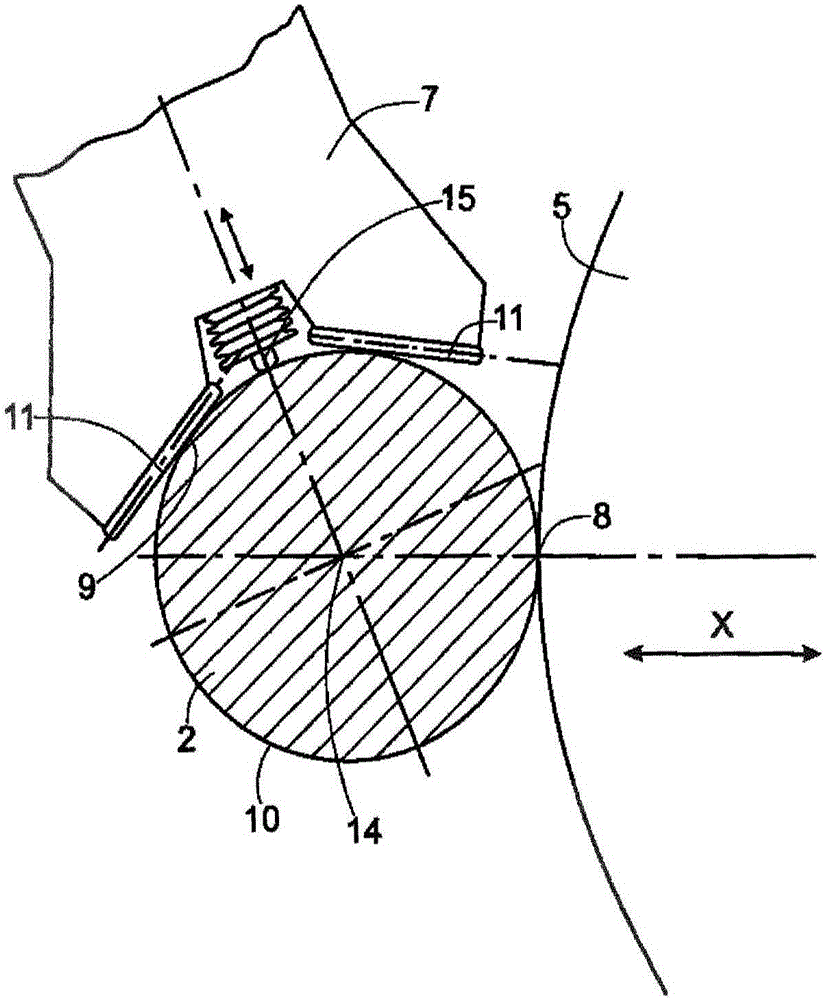

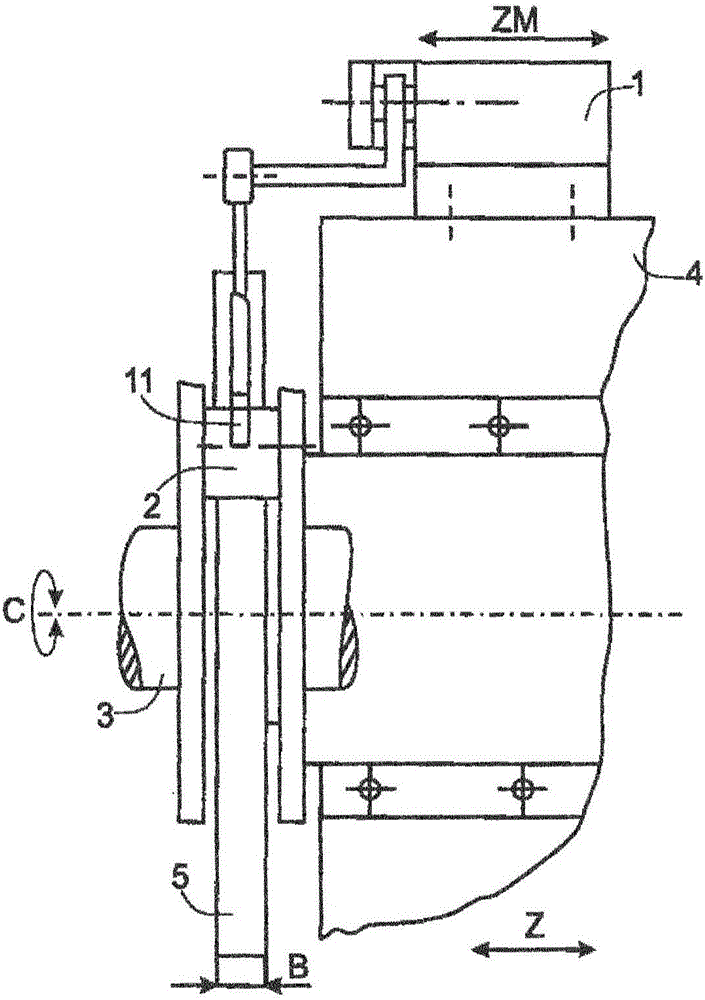

[0045] In FIG. 1 , a schematic diagram is shown of a structure showing the process of grinding a pin bearing journal 2 by means of a grinding disc 5 capable of carrying out a pendulum movement. Grinding mandrel tailstock 4 carries measuring device 1 on its upper area with respect to grinding disc 5 , said measuring device is able to proceed from the abutment position in which it abuts against a pin to be measured on crankshaft 3 The measuring arm on the bearing journal 2 moves according to the solid line to the retracted position where it has no measuring function, and then moves along the dotted line. The grinding disc 5 with its axis of rotation 13 can be advanced in a controlled manner by means of the CNC-controlled X-axis towards the pin bearing journal to be ground. The axis of rotation 13 of the grinding disc is also called the C-axis and is likewise controlled by the CNC. The elements required for realizing the movement in the X direction as well as the workpiece spind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com