Tension control device of fiber sizing equipment of winding machine and control method thereof

A technology of tension control and winding machine, which is applied in the program control of sequence/logic controller, electrical program control, transportation and packaging, etc. It can solve the problems of unable to control the tension value in real time, unable to adjust the size of tension, large errors, etc. , to achieve the effects of convenient operation, improved measurement accuracy, and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

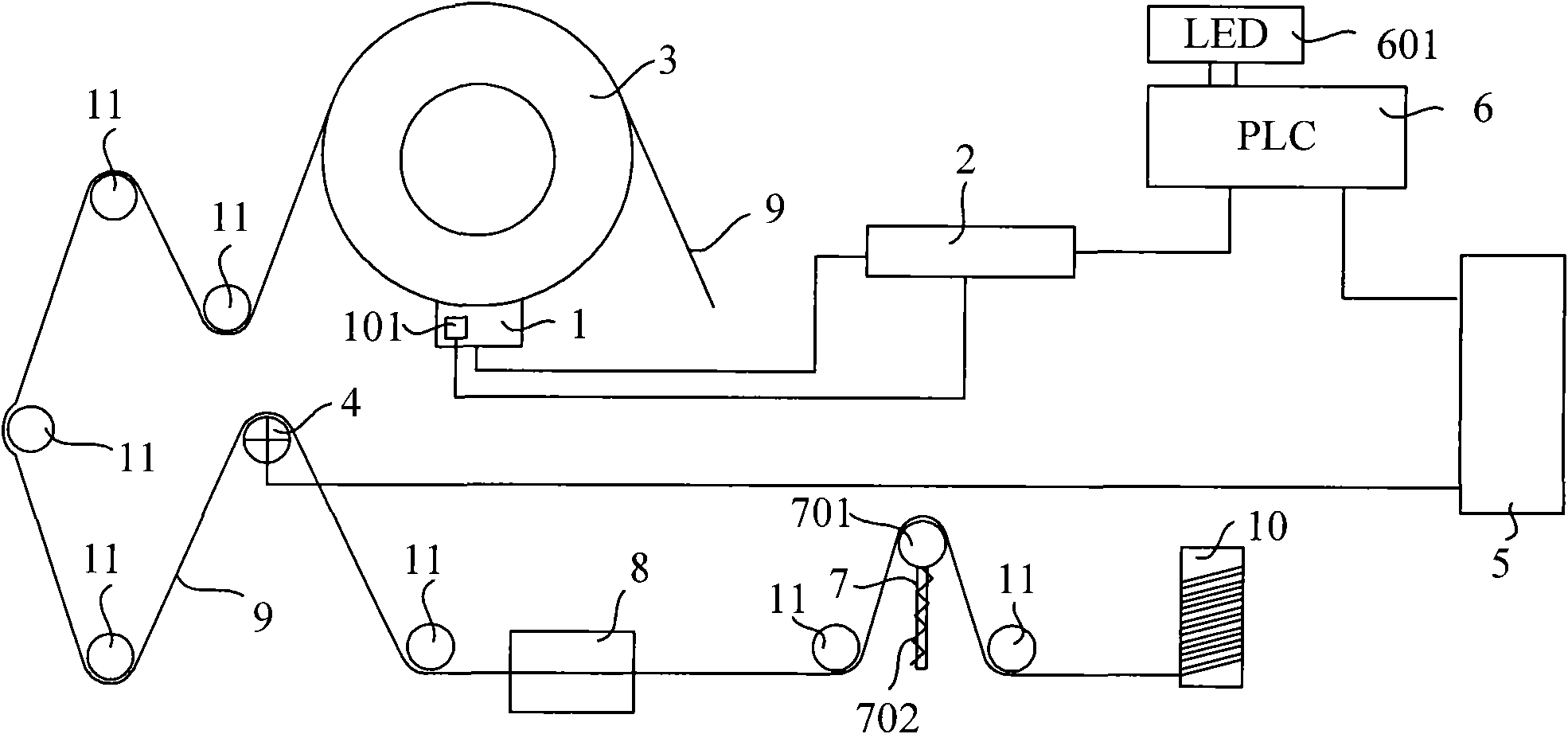

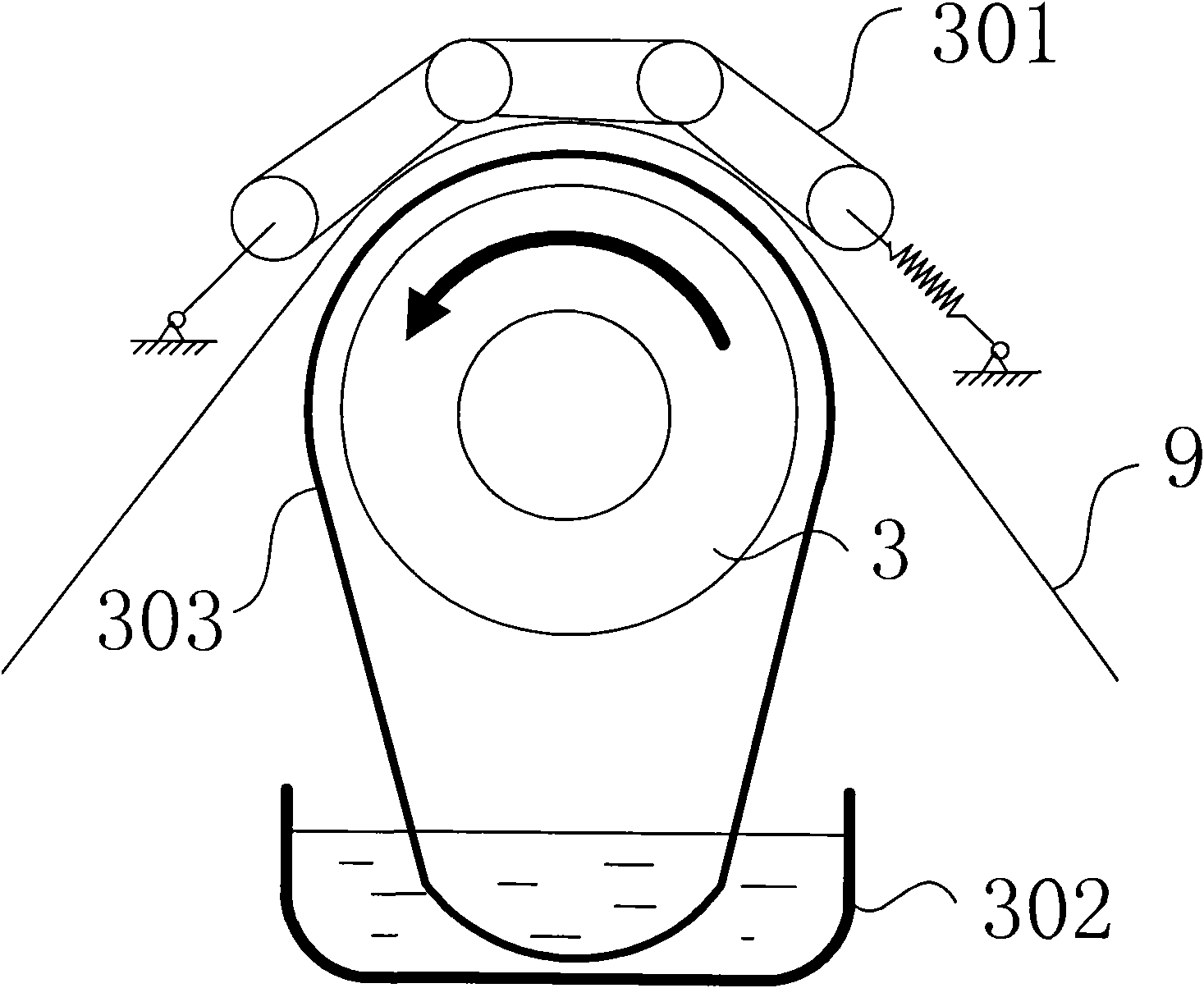

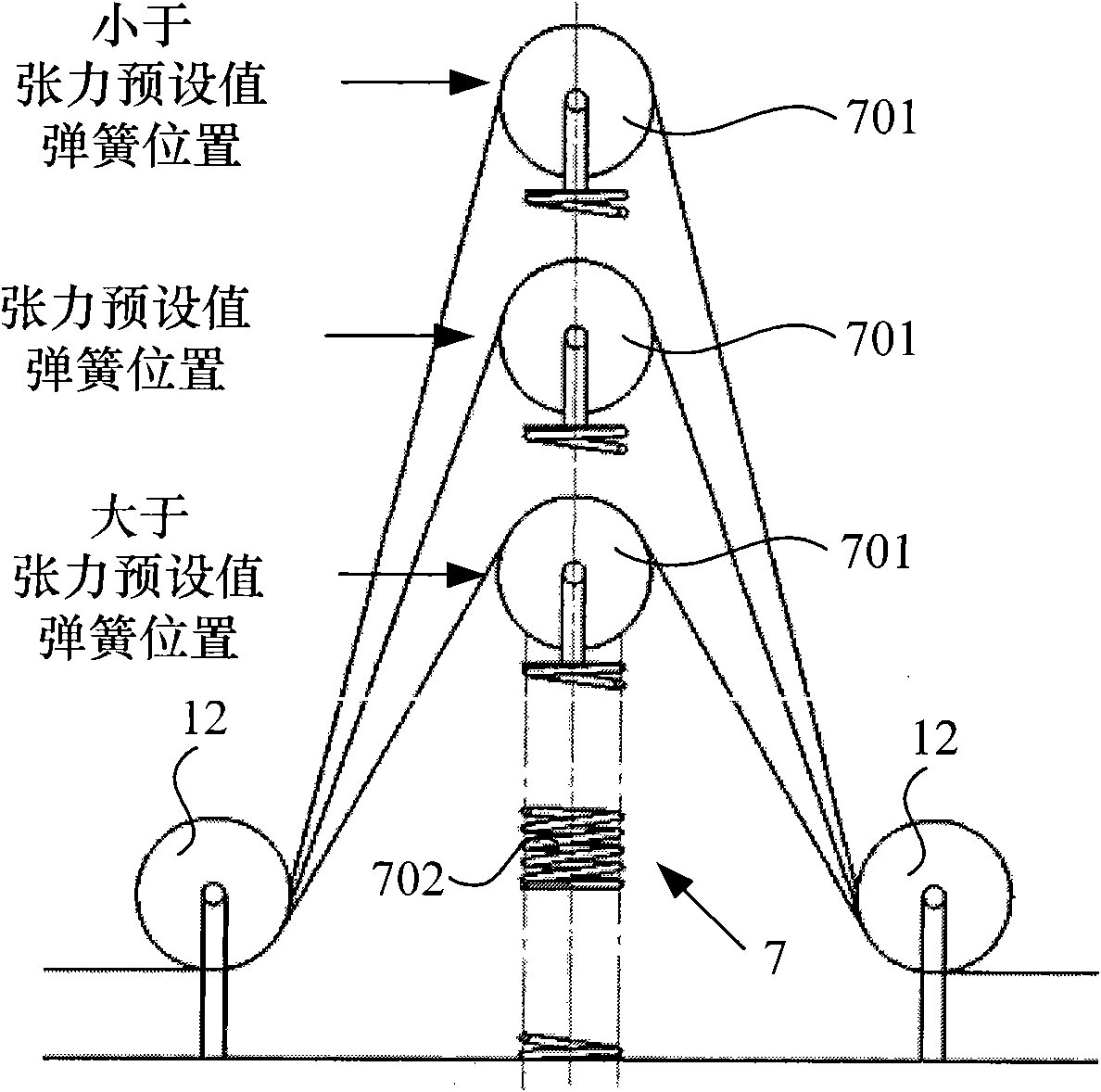

[0037] The invention is a tension control device for fiber gluing equipment of a winding machine, such as figure 1 As shown, it includes servo motor 1, motor driver 2, dipping roller 3, tension sensor 4, tension signal amplifier 5, PLC controller 6, spring guide roller 7, scraping plate 8 and roller 11, and all the above devices are fixed Mounted on the rack.

[0038] The servo motor 1 is provided with a rotary encoder 101, the servo motor 1 is connected to the dipping roller 3, drives the dipping roller 3 to drive the fiber 9 to run counterclockwise, the rotary encoder 101 is connected to the motor driver 2, and transmits the speed signal of the servo motor 1 to The motor driver 2, the servo motor 1 is also connected to the motor driver 2, the motor driver 2 controls the speed of the servo motor 1, the other end of the motor driver 2 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com