Preparation device and preparation method of cellulose-based fiber membrane with nanostructure

A cellulose-based and nano-structured technology, which is applied in fiber processing, textiles, papermaking, non-woven fabrics, etc., can solve the problems of inability to prepare small-sized, high-performance nano-cellulose fiber membranes, and achieve controllable spinning conditions , high porosity and small fiber size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

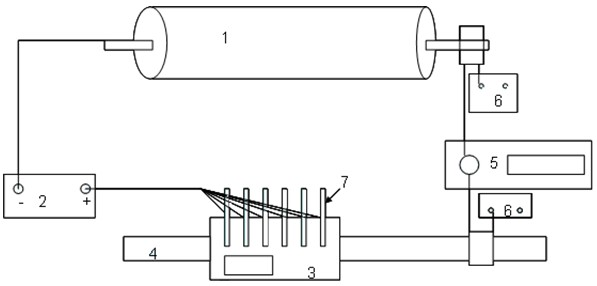

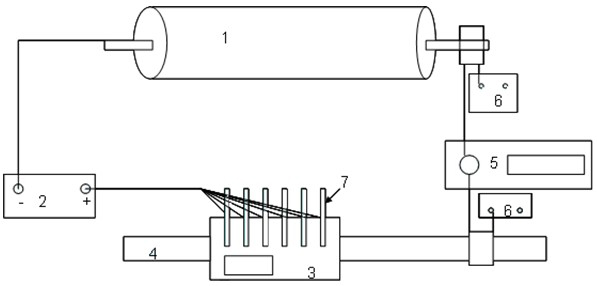

[0023] Such as figure 1 Shown is a schematic structural diagram of a device for preparing a cellulose fiber membrane with nanostructures. The device for preparing a cellulose fiber membrane with nanostructures includes a rotatable sliding table 4 and a liquid injection pump 3 located at On the sliding table 4, when the sliding table 4 rotates, the liquid supply injection pump 3 moves along the sliding table 4, and the liquid supply injection pump 3 is fixedly connected to the spinneret 7. A rotary receiving device 1 (ie Roller collector), the spinneret 7 and the rotary receiving device 1 are connected to the high-voltage power supply 2, and the sliding table 4 and the rotating shaft of the rotary receiving device 1 are connected to the motor 6 and the speed controller 5. When in use, the spinning solution is delivered to the spinneret 7 through the liquid supply injection pump 3, and the high-voltage power supply 2 is turned on to start electrostatic spinning. The thickness and...

Embodiment 2

[0025] Using the device described in Example 1, at room temperature 25 o Under C, add 3 g of cellulose acetate butyrate (weight average molecular weight 70,000 g / mol) into a closed container containing 7 g of acetic acid / acetone (weight ratio 1 / 3) solution, and stir vigorously at 50 rpm on a magnetic stirrer until The cellulose acetate butyrate was completely dissolved, the solution was a colorless and transparent liquid, and a cellulose acetate butyrate solution with a mass fraction of 30% was obtained.

[0026] At room temperature 25 o Under the condition of C, the prepared cellulose acetate butyrate solution is subjected to electrospinning under high voltage conditions. The electrospinning conditions are: ambient relative humidity 40%, voltage 25kV, and the number of spinnerets is 5. The moving speeds of the drum collector and spinneret were 50 rpm and 5 m / min, respectively, the solution input speed to each spinneret was 2mL / h, the receiving distance was 12cm, and the spinning ...

Embodiment 3

[0028] Using the device described in Example 1, at room temperature 25 o At C, add 1.25g cellulose acetate (number average molecular weight 30,000) to 8.75g acetone / dimethylacetamide (weight ratio 2 / 1) solution, and stir vigorously at 70rpm on a magnetic stirrer until the cellulose acetate Completely dissolved, the solution was a colorless and transparent liquid, and a cellulose acetate butyrate solution with a mass fraction of 12.5% was obtained.

[0029] At room temperature 25 o Under the condition of C, the prepared cellulose acetate solution is electrospinned under high voltage conditions. The electrospinning conditions are: the relative humidity of the environment is 40%, the voltage is 15kV, the number of spinnerets is 20, and the drum is collected The moving speed of the spinneret and the spinneret are 50 rpm and 10 m / min, respectively, the solution input speed to each spinneret is 2mL / h, and the receiving distance is 10cm. The material of the drum collector is aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com