Degradable mask and preparation method thereof

A technology of masks and polylactic acid, which is applied in the field of masks, can solve the problems of slow degradation of masks and environmental damage, and achieve the effects of small site ratio, high charge load, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

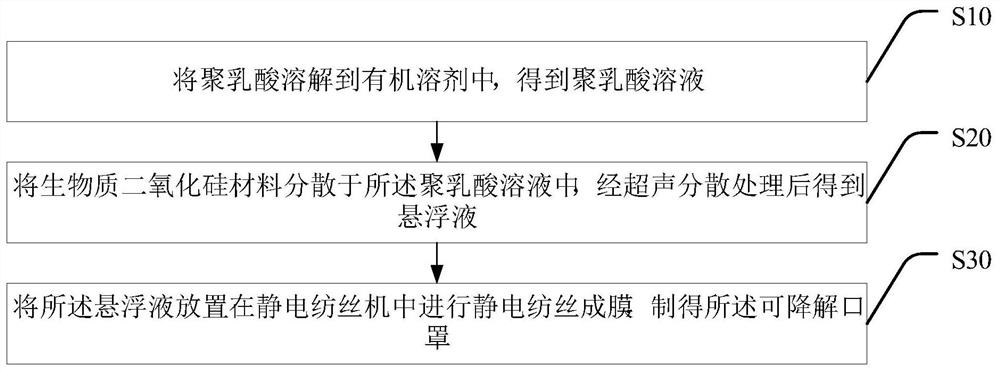

Method used

Image

Examples

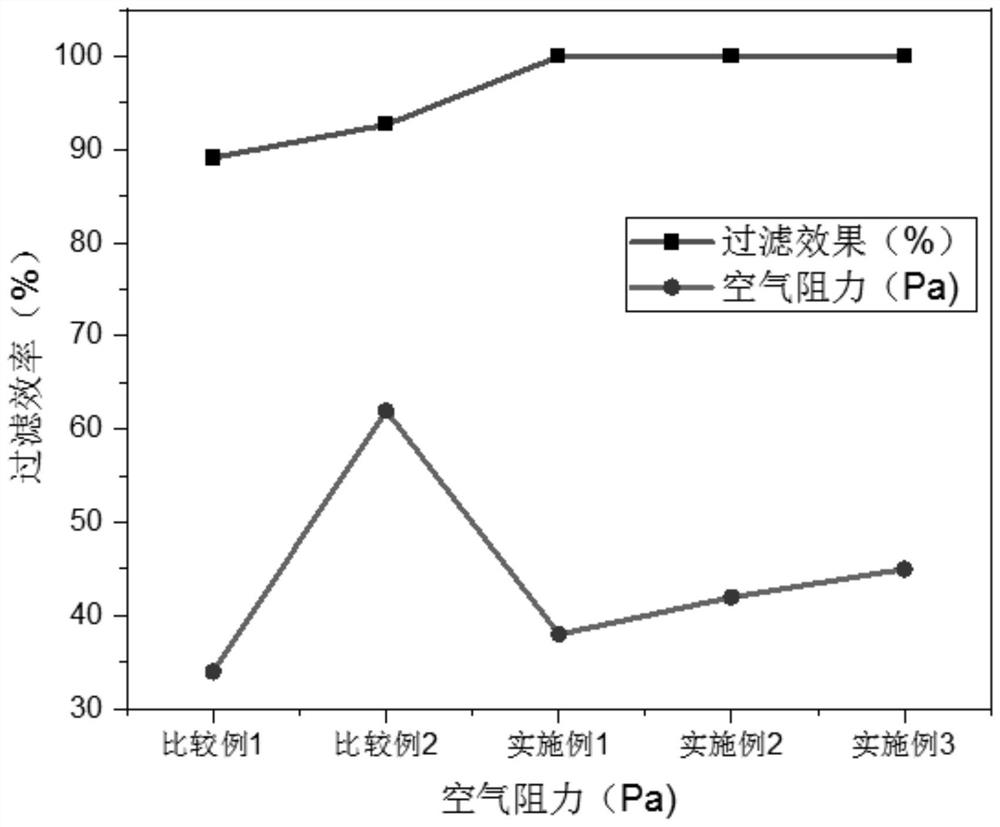

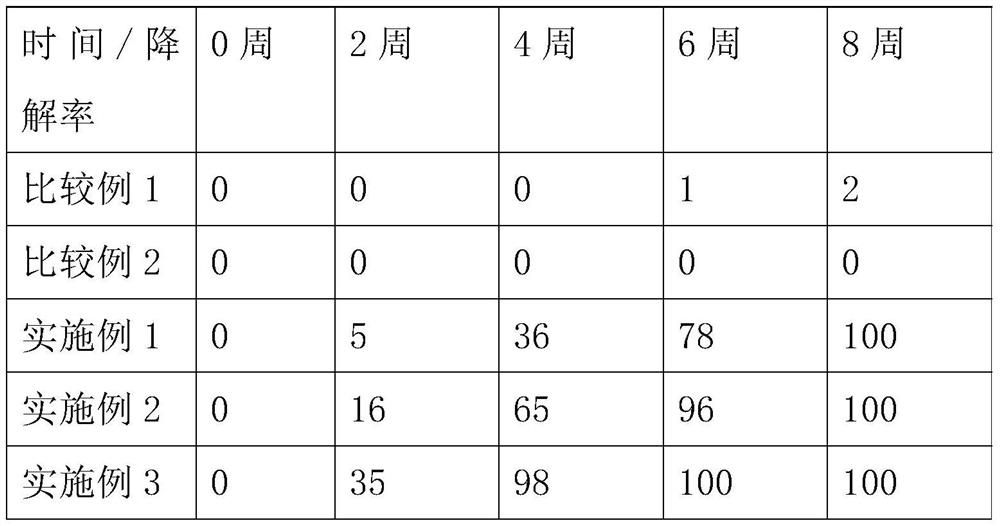

Embodiment 1

[0045] Dissolve polylactic acid and diatomaceous earth in DMF at a mass ratio of 9:1 to prepare a spinning solution with a mass concentration of 0.1g / mL, draw the mixed solution with a needle, and fix the distance between the collecting plate and the spinneret at 12cm , start spinning after setting the DC voltage of 15KV. After electrospinning, a layer of polylactic acid / diatomaceous earth composite degradable mask was collected on the collector.

Embodiment 2

[0047] Dissolve polylactic acid and diatomaceous earth in DMF at a mass ratio of 5:5 to prepare a spinning solution with a mass concentration of 0.1 g / mL, draw the mixed solution with a needle, and fix the distance between the collecting plate and the spinneret at 15 cm , Start spinning after setting the DC voltage of 20KV. After electrospinning, a layer of polylactic acid / diatomaceous earth composite degradable mask was collected on the collector.

Embodiment 3

[0049] Dissolve polylactic acid and diatomaceous earth in DMF at a mass ratio of 2:8 to prepare a spinning solution with a mass concentration of 0.1g / mL, draw the mixed solution with a needle, and fix the distance between the collecting plate and the spinneret at 17cm , start spinning after setting the DC voltage of 25KV. After electrospinning, a layer of polylactic acid / diatomaceous earth composite degradable mask was collected on the collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com