Porous electrode for liquid flow battery and preparation method thereof

A porous electrode, flow battery technology, applied in battery electrodes, circuits, electrospinning, etc., can solve problems such as sacrificing electrode transmission performance, and achieve the effect of ensuring mechanical properties, increasing active area, and improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

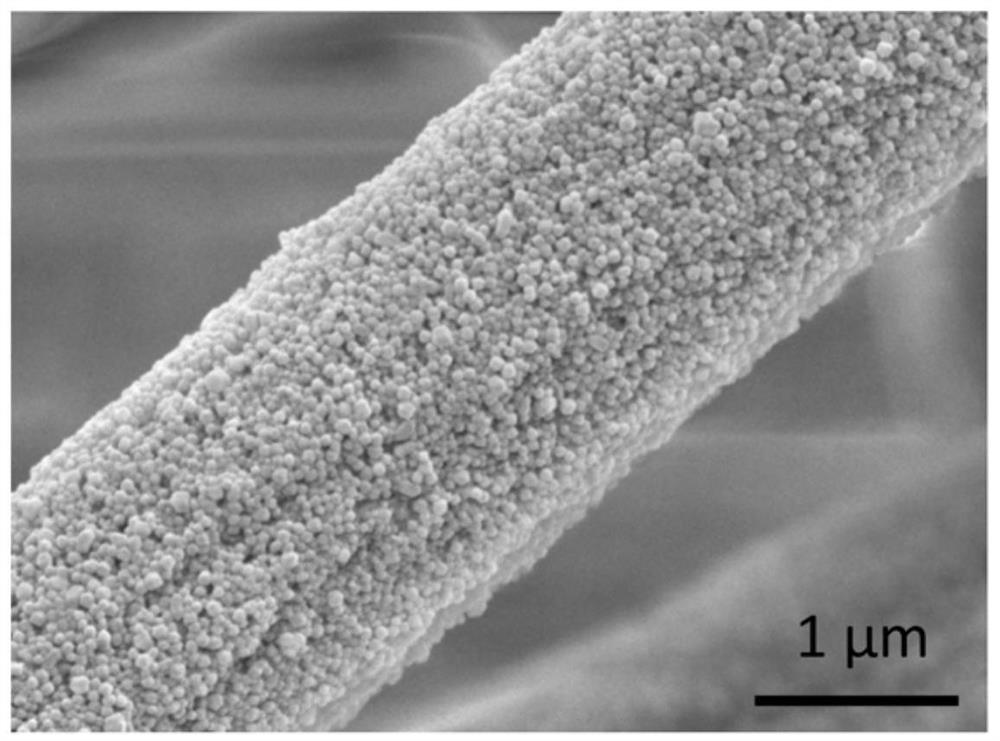

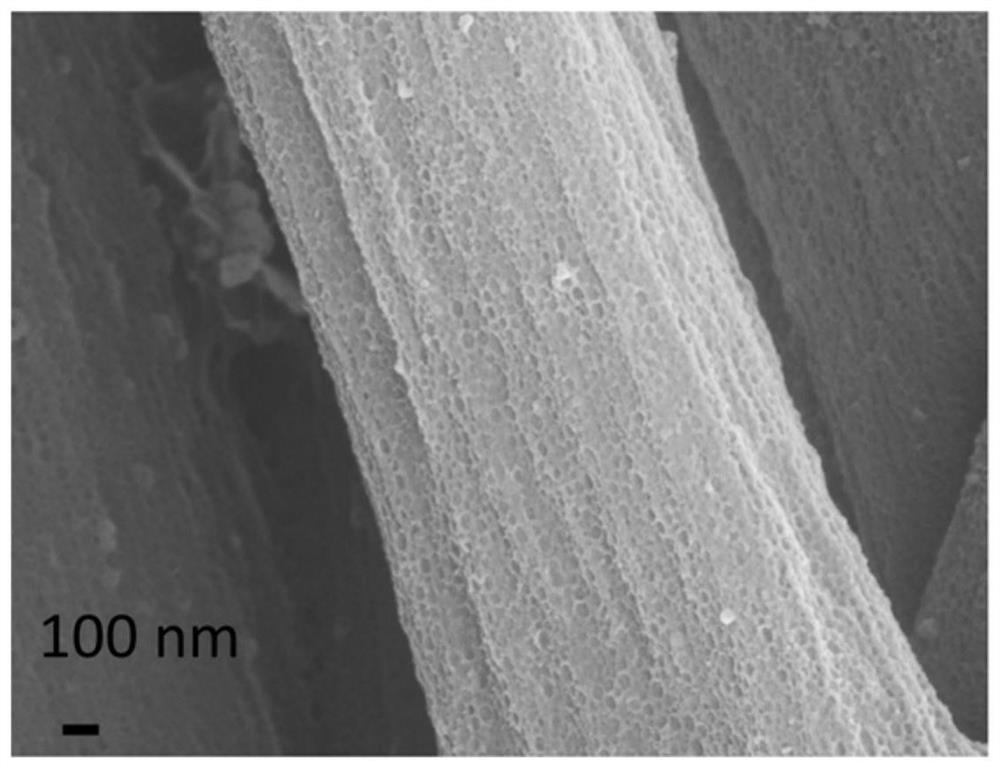

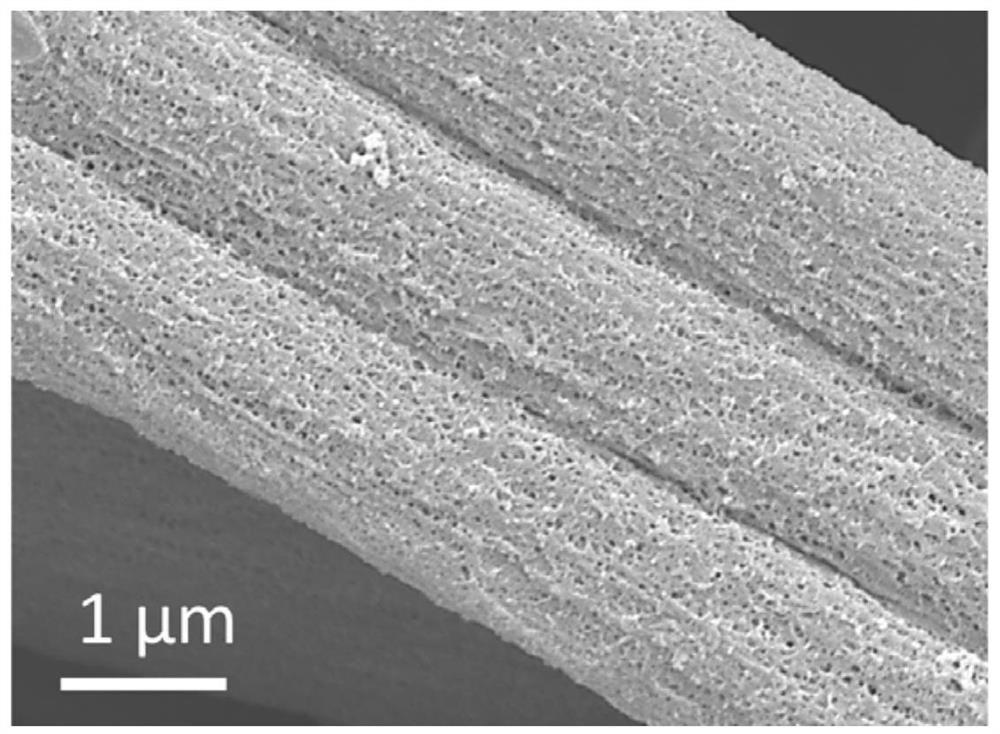

Image

Examples

Embodiment 1

[0036] A porous electrode prepared by the following method:

[0037] (1) Mix 2g of polyacrylonitrile (PAN), 1g of zinc nitrate and 17g of N,N-dimethylformamide, heat and dissolve in a water bath at 70°C, and prepare an electrospinning stock solution.

[0038] (2) Take 15mL of the electrospinning stock solution from step 1, connect it to a 20G (0.60mm inner diameter) needle, and set the advancing speed of the electrospinning stock solution to 1.0mL h -1 , the electrospinning voltage was 17kV, the distance from the needle to the receiving end was 20cm, and the rotating speed of the receiving wheel was 200rpm. The ambient temperature of electrospinning was 25 °C and the relative humidity was 55%. The electrospun fiber membrane was removed after spinning for 10 h.

[0039](3) Weigh 1g of 2-methylimidazole and dissolve it in 200mL of a mixed solution of methanol and ethanol with a volume ratio of 1:1, cut the electrospun fiber membrane (4cm×4cm) in step 2 and soak it in the 2-met...

Embodiment 2

[0047] A porous electrode prepared by the following method:

[0048] (1) Weigh 2g of polyacrylonitrile, 1g of zinc acetate and 17g of N,N-dimethylformamide, mix them, heat and dissolve in a 70°C water bath, and prepare an electrospinning stock solution.

[0049] (2) Take 15mL of the electrospinning stock solution from step 1, connect it to a 20G (0.60mm inner diameter) needle, and set the advancing speed of the electrospinning stock solution to 1.0mL h -1 , the electrospinning voltage is 17kV, the distance from the needle to the receiving end is 20cm, and the rotating speed of the receiving wheel is 200rpm. The ambient temperature of electrospinning was 25 °C and the relative humidity was 55%. The electrospun fiber membrane was removed after spinning for 10 h.

[0050] (3) Weigh 1g of 2-methylimidazole and dissolve it in 200mL of a mixed solution of methanol and ethanol with a volume ratio of 1:1, cut the electrospun fiber membrane (4cm×4cm) in step 2 and soak it in the 2-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com