Preparation method for cerium oxide with structure of multilevel pore canals

A technology of pore structure and cerium oxide, which is applied in the fields of chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve problems such as complex methods, difficult to control pore structure, and unsuitable for mass production, and achieve simple preparation methods , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

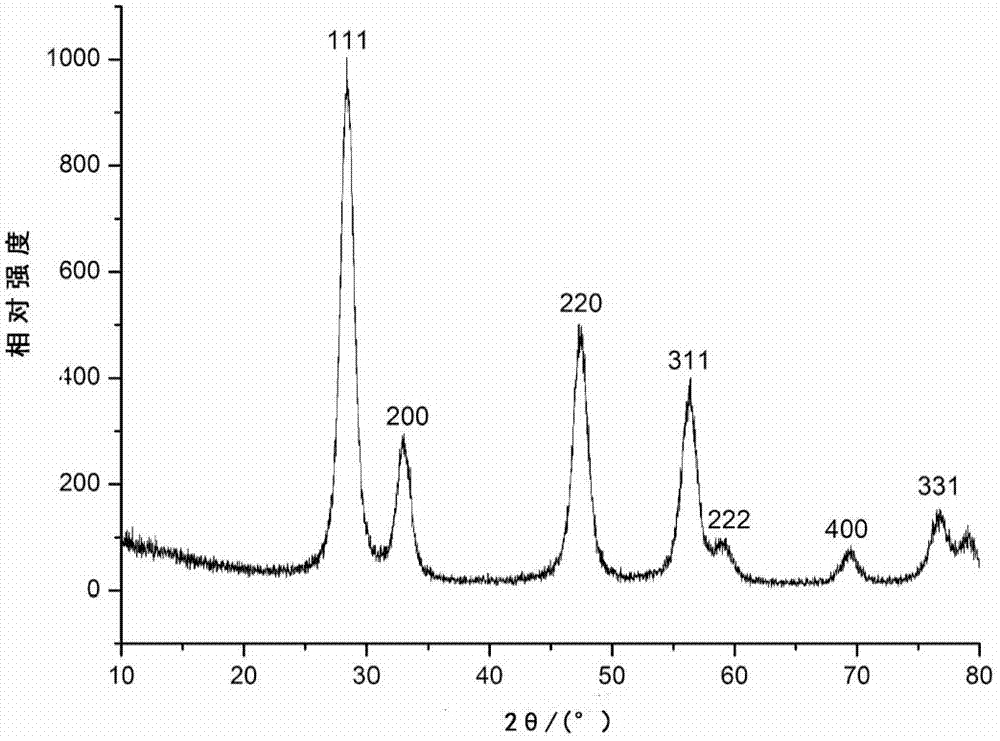

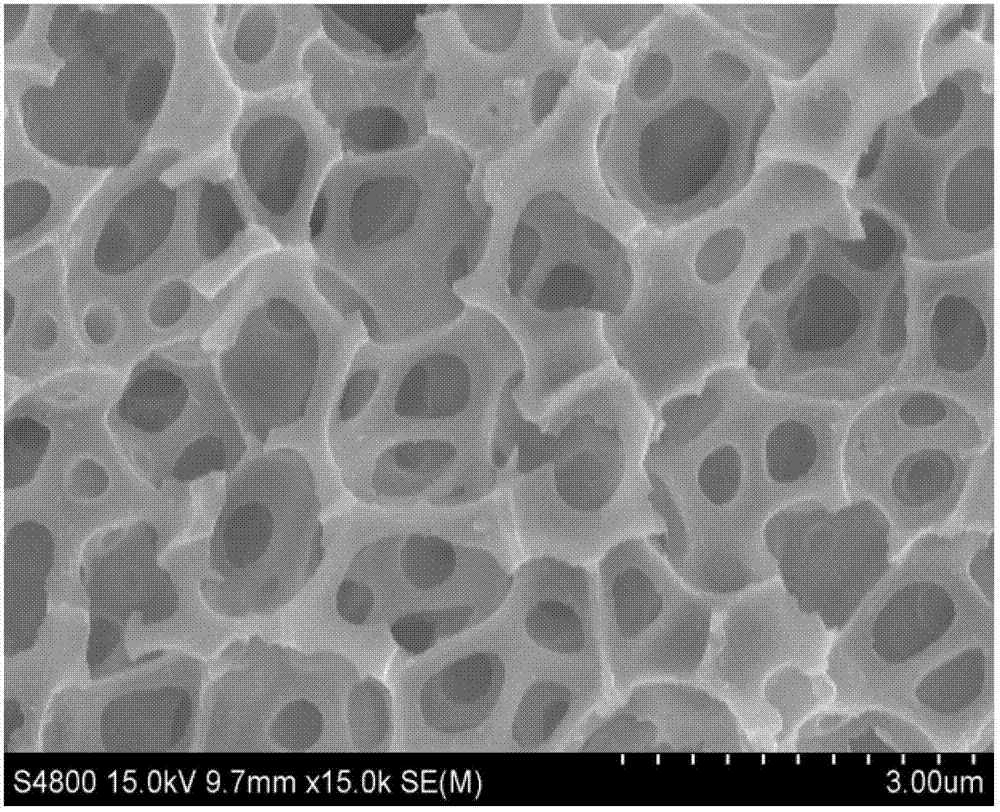

[0019] Artemia egg shells were cleaned with distilled water, and after ball milling for 6 hours, they were washed with HCl with a concentration of 6mol / L and HCl with a concentration of 8mol / L. 2 SO 4 , 6mol / L HNO 3 , 2mol / L KOH soaking pretreatment, the soaking time is 2h for each substance, and dry to remove water; dissolve 0.126g Pluronic F127 in 5mL water and 5mL ethanol, add 0.5g cerium nitrate, 0.484g citric acid, and stir for 0.5h ; Add 0.5 g of the above-treated Artemia egg shells and let stand for 2 hours, filter with suction, and dry in vacuum at 80° C. for 6 hours. Then control the calcination temperature of 300° C. for 3 hours at a heating rate of 1° C. / min to keep the dried product at a temperature of 400° C. and keep it for 4 hours to obtain multi-level porous ceria. Such as figure 1 As shown, the analysis shows that the product is pure phase ceria.

Embodiment 2

[0021] Artemia egg shells were cleaned with distilled water, and after ball milling for 6 hours, they were washed with HCl with a concentration of 9mol / L and HCl with a concentration of 13mol / L. 2 SO 4 , 10mol / L of HNO 3 , 4mol / L KOH soaking pretreatment, soaking time is 4h for each substance, drying to remove moisture; dissolving 0.074g CTAB in 8mL water and 6mL ethanol, adding 3.75g cerium acetate, 2.90g citric acid, and stirring for 1.25h; After adding 1.5 g of the above-treated Artemia egg shells, let stand for 4 hours, filter with suction, and dry in vacuum at 90° C. for 15 hours. Then, the obtained dried product is controlled at a heating rate of 5.5° C. / min, and the calcination temperature is controlled at 300° C. for 3 hours, and the calcination temperature is 600° C., and kept for 5 hours to obtain multi-level porous cerium oxide.

Embodiment 3

[0023] Clean Artemia egg shells with distilled water, and after ball milling for 6 hours, use HCl with a concentration of 12mol / L and HCl with a concentration of 18mol / L respectively. 2 SO 4 , 14mol / L HNO 3 , 6mol / L KOH soaking pretreatment, the soaking time is 6h for each substance, and dry to remove water; dissolve 0.1093g CTAB in 6mL water and 4mL ethanol, add cerium acetate 7g, citric acid 3.61g, stir for 2h; add 2.5 g. After the above-mentioned treated Artemia egg shells were left to stand for 6 hours, they were suction filtered and dried in vacuum at 100° C. for 24 hours. Then, the obtained dried product is controlled at a heating rate of 10° C. / min, and the calcining temperature is controlled at 300° C., kept for 3 hours, and the calcined temperature is 800° C., kept for 6 hours to obtain multi-level porous cerium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com