Compressing-deslagging-drilling dust remover for coal pits

A dust collector and coal mine technology, applied in the fields of dust prevention, mining equipment, earth-moving drilling, etc., can solve the problems of large equipment volume, strong airflow impact, threatening the health of operators, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

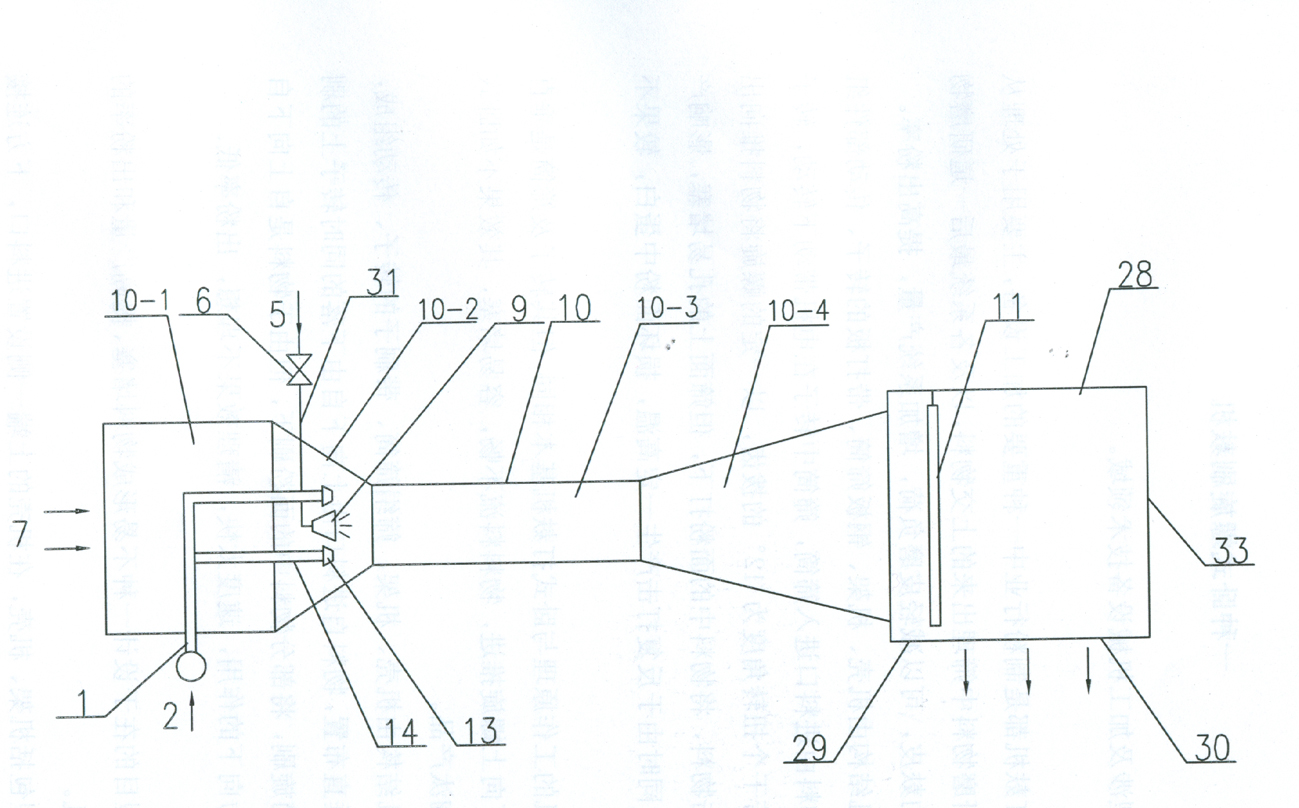

[0026] like figure 1 As shown, it is a coal mine underground dust collector with compressed air and slag discharge drilling, including a Venturi mixer 10, and the Venturi mixer 10 includes an air inlet chamber 10-1, a shrinkage pipe section 10-2, a straight pipe section 10-3 and a cone Shaped diffusion section 10-4. A high-pressure gas inlet pipe 1 is arranged in the air inlet chamber 10-1, the outer end of the high-pressure gas inlet pipe 1 is arranged outside the air inlet chamber 10-1, and the inner end of the high-pressure gas inlet pipe 1 is connected with two venturi tubes for mixing A straight pipe 14 parallel to the central axis of the device 10, the other end of the straight pipe 14 is equipped with a high-pressure gas nozzle 13, and the outlet of the high-pressure gas nozzle 13 is arranged at the shrinkage pipe section 10-2.

[0027] A water inlet pipe 31 is also arranged on the shrinkage pipe section 10-2 of the Venturi tube mixer 10, and a valve 6 is installed on ...

Embodiment 2

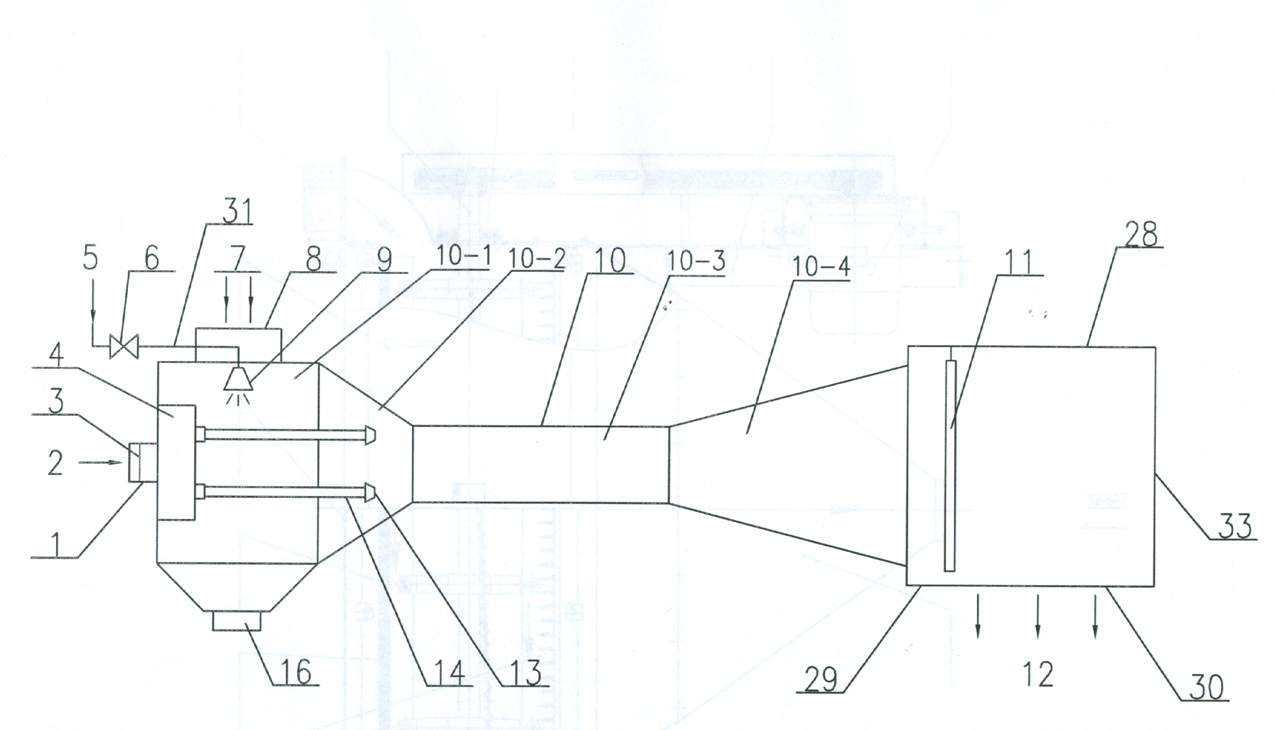

[0030] like figure 2 As shown, a high-pressure gas distribution chamber 4 is set between the high-pressure gas inlet pipe 1 and the straight pipe 14 , the high-pressure gas distribution chamber 4 is set in the air intake chamber 10 - 1 , and each straight pipe 14 is arranged at one end of the high-pressure gas distribution chamber 4 . The upper end of the air intake chamber 10 - 1 is connected to the dust-laden airflow inlet pipe 8 , and the axis of the dust-laden airflow inlet pipe 8 is perpendicular to the axis of the Venturi tube mixer 10 . A first filter screen 3 is arranged in the high-pressure gas inlet pipe 1 . The water inlet pipe 31 is passed through the air inlet chamber 10-1, and the water atomization nozzle 9 is arranged in the air inlet chamber 10-1. The lower end of the air inlet chamber 10-1 is connected with the slag discharge port 16. All the other structures are with embodiment 1.

[0031] The high-pressure gas 2 enters the high-pressure gas distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com