Compressing-deslagging-drilling dust remover for coal pits

A technology for dust collectors and coal mines, applied in dust prevention, mining equipment, earthwork drilling and mining, etc. It can solve the problems of large equipment volume, high gas concentration, difficulty in adapting to frequent replacement of drilling positions, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

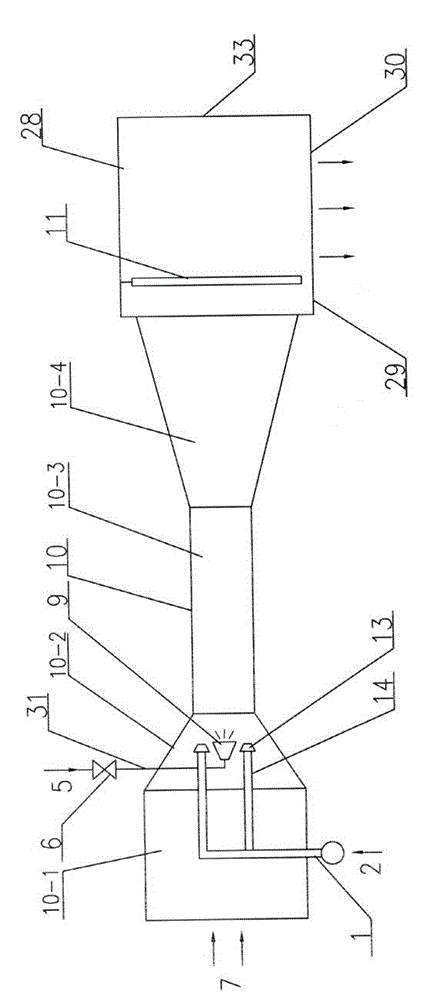

[0026] like figure 1 As shown, it is a coal mine underground dust collector with compressed air and slag discharge drilling, including a Venturi mixer 10, and the Venturi mixer 10 includes an air inlet chamber 10-1, a shrinkage pipe section 10-2, a straight pipe section 10-3 and a cone Shaped diffusion section 10-4. A high-pressure gas inlet pipe 1 is arranged in the air inlet chamber 10-1, the outer end of the high-pressure gas inlet pipe 1 is arranged outside the air inlet chamber 10-1, and the inner end of the high-pressure gas inlet pipe 1 is connected with two venturi tubes for mixing A straight pipe 14 parallel to the central axis of the device 10, the other end of the straight pipe 14 is equipped with a high-pressure gas nozzle 13, and the outlet of the high-pressure gas nozzle 13 is arranged at the shrinkage pipe section 10-2.

[0027] A water inlet pipe 31 is also arranged on the shrinkage pipe section 10-2 of the Venturi tube mixer 10, and a valve 6 is installed on ...

Embodiment 2

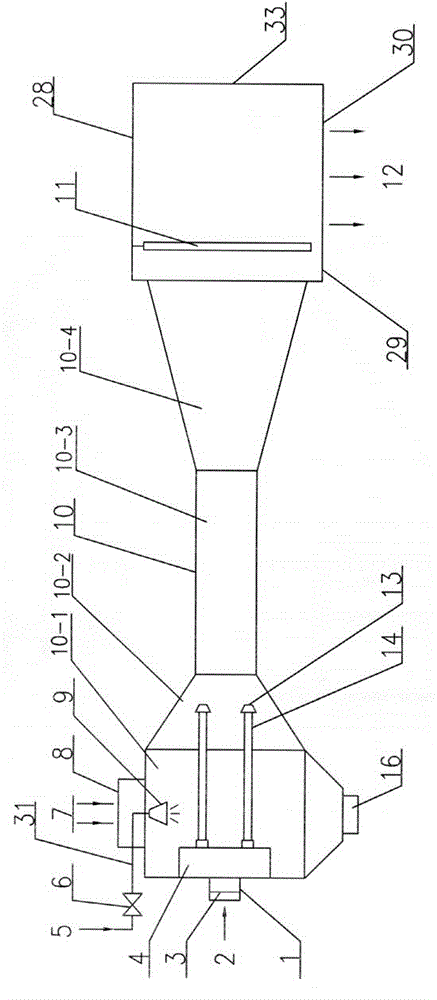

[0030] like figure 2 As shown, a high-pressure gas distribution chamber 4 is set between the high-pressure gas inlet pipe 1 and the straight pipe 14 , the high-pressure gas distribution chamber 4 is set in the air intake chamber 10 - 1 , and each straight pipe 14 is arranged at one end of the high-pressure gas distribution chamber 4 . The upper end of the air intake chamber 10 - 1 is connected to the dust-laden airflow inlet pipe 8 , and the axis of the dust-laden airflow inlet pipe 8 is perpendicular to the axis of the Venturi tube mixer 10 . A first filter screen 3 is arranged in the high-pressure gas inlet pipe 1 . The water inlet pipe 31 is passed through the air inlet chamber 10-1, and the water atomization nozzle 9 is arranged in the air inlet chamber 10-1. The lower end of the air inlet chamber 10-1 is connected with the slag discharge port 16. All the other structures are with embodiment 1.

[0031] The high-pressure gas 2 enters the high-pressure gas distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com