Drilling slag dust collector for underground coal mine

A technology for dust collectors and coal mines, applied in dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of high gas concentration, large equipment volume, harsh environment, etc., and achieve the effect of light weight, small volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

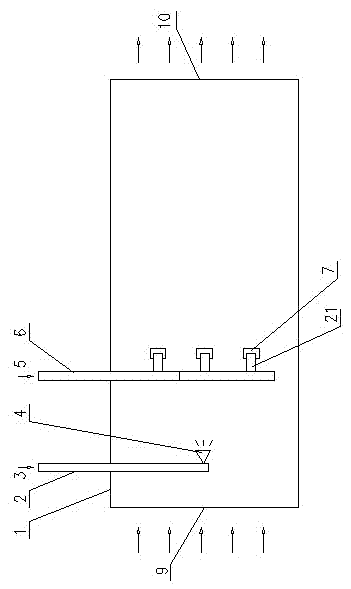

Embodiment 1

[0029] Such as figure 1 As shown, it is a coal mine underground drilling slag removal dust collector, including a straight pipe 1, a water pipe 2 and a gas pipe 6, the front end of the straight pipe 1 is an air inlet 9, and the rear end of the straight pipe 1 is an exhaust port 10. The water pipe 2 is placed on the straight pipe 1 , and one end of the water pipe 2 in the straight pipe 1 is connected to the water atomizing nozzle 4 , and the water atomizing nozzle 4 faces the exhaust port 10 . The gas pipe 6 is placed on the straight pipe 1, and the gas pipe 6 in the straight pipe 1 is connected with three branch pipes 21, each branch pipe 21 is respectively arranged parallel to the central axis of the straight pipe 1, and the other end of each branch pipe 21 is respectively The gas shower heads 7 are connected, and each gas shower head 7 faces the exhaust port 10 respectively. The water atomizing nozzle 4 is arranged between the air inlet 9 and the gas nozzle 7 .

[0030] Hi...

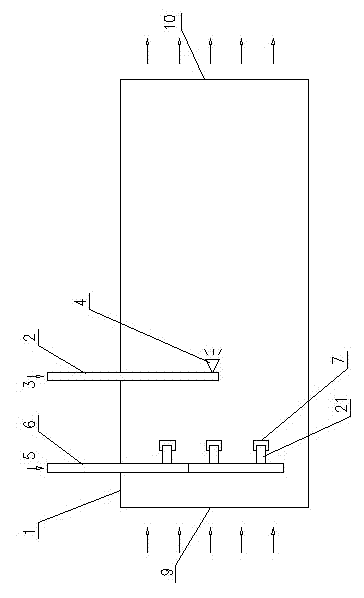

Embodiment 2

[0032] Such as figure 2 As shown, the gas nozzle 7 is arranged between the air inlet 9 and the water atomization nozzle 4 . All the other structures are with embodiment 1.

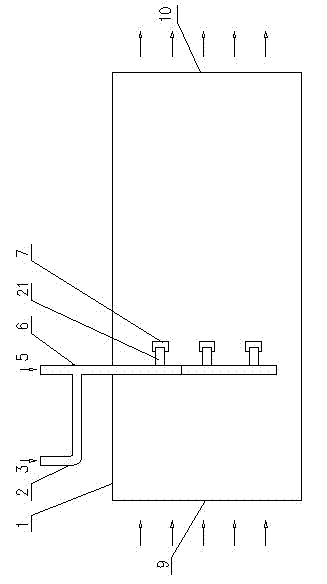

Embodiment 3

[0034] Such as image 3 As shown, it includes a straight pipe 1, a water pipe 2 and a gas pipe 6. The front end of the straight pipe 1 is an air inlet 9, and the rear end of the straight pipe 1 is an exhaust port 10. The gas pipe 6 is placed on the straight pipe 1, and the gas pipe 6 in the straight pipe 1 is connected with three branch pipes 21, each branch pipe 21 is respectively arranged parallel to the central axis of the straight pipe 1, and the other end of each branch pipe 21 is respectively The gas shower heads 7 are connected, and each gas shower head 7 faces the exhaust port 10 respectively. The water pipe 2 is next to the gas pipe 6 outside the straight pipe 1. The water pipe 2 and the gas pipe 6 are combined into one pipe. In this way, the compressed air 5 and the high-pressure water 3 (the volume occupied by the high-pressure water is very small) are sprayed at the gas nozzle 7 at high speed, and the water is atomized into droplets during the high-speed spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com