Liquid-solid circulating fluidized bed waste water treatment system for simultaneous carbon, nitrogen and phosphorus removal

A circulating fluidized bed, fluidized bed technology, applied in the field of fluidized bed, can solve the problem of low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

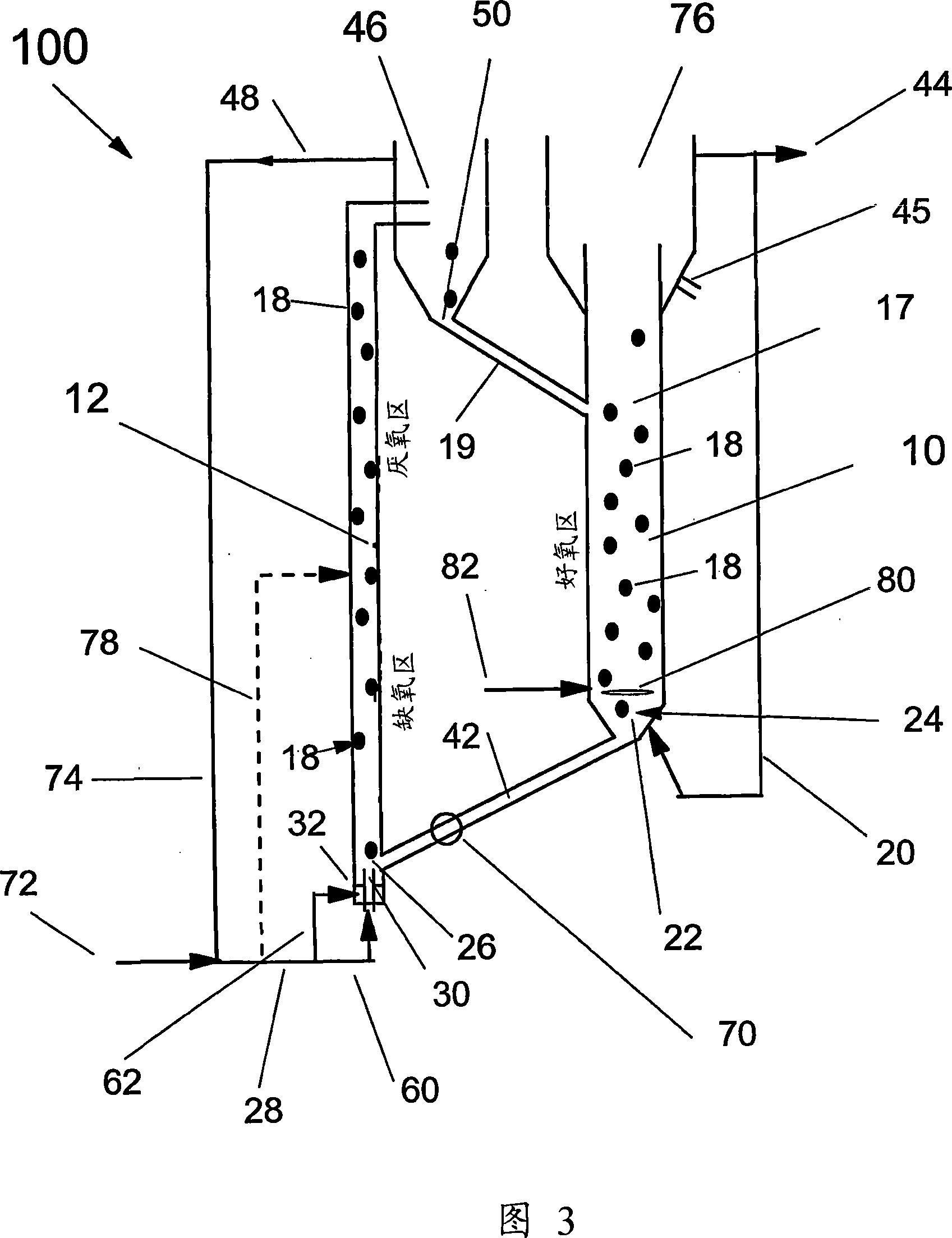

[0039] A flow diagram of the fixed film biological nutrient removal process used in the liquid-solid circulating fluidized bed 100 (FIG. 3) of the present invention is depicted in FIG. Referring to FIG. 3 , the aerobic process occurs in the downflow bed 10 , the anoxic process occurs in the lower portion of the upflow bed 12 , and the anaerobic process occurs in the upper portion of the upflow bed 12 . It is also possible to make the anoxic process take place in the upper part of the uplifted bed, and the anaerobic process take place in the lower part of the uplifted bed. But at this time, most of the nitrification effluent from the aerobic zone needs to be supplied to the bottom of the anoxic zone in the middle of the ascending fluidized bed. Raw sewage 72 (primary influent or primary effluent) is first mixed with anoxic / anaerobic effluent recirculation stream 74 from liquid-solid separator 46 at the top of the raised bed and then fed into the bottom of the raised bed 12, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com