Method for preparing light foam concrete by using compound protein foaming agent

A technology of protein foaming agent and lightweight foam, which is applied in the field of preparing light foam concrete by using compound protein foaming agent, compound protein foaming agent, and preparing non-steamed light foam concrete, which can solve the problem of high cost, The process is complicated, and the stability of the sludge hydrolyzed protein foaming agent is not well solved, so as to achieve the effect of improving the foam stability and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for lightweight foamed concrete, comprising the steps of:

[0029] Formulated blowing agent

[0030] The components are: 10g of activated sludge protein with a mass concentration of 15%, 0.3g of vegetable protein with a mass concentration of 40%, 0.2g of methylcellulose and 89.5g of water, fully mixed to obtain a foaming agent;

[0031] Prepare cement paste

[0032] The components are: 40g of cement, 25g of fly ash, 5g of lime, 2g of gypsum, 0.5g of polycarboxylate superplasticizer and 27.5g of water, and stir evenly to obtain cement slurry.

[0033] After the foaming agent is foamed, the foam is added to the cement slurry, stirred rapidly for 3 minutes, introduced into a mold, and naturally cured for 28 days to obtain a foam concrete block.

Embodiment 2

[0035] A preparation method for lightweight foamed concrete, comprising the steps of:

[0036] Formulated blowing agent

[0037] Components are: 11.5g mass concentration is 18% activated sludge protein, 0.2g mass concentration is 40% plant protein, 0.1g hydroxymethyl cellulose, 0.1g gum arabic and 88.1g water are fully mixed to obtain hair foaming agent;

[0038] Prepare cement paste

[0039] The components are: 30g of cement, 35g of fly ash, 6g of lime, 1g of gypsum, 0.5g of polycarboxylate superplasticizer and 27.5g of water, and stir evenly to obtain cement slurry.

[0040] After the foaming agent is foamed, the foam is added to the cement slurry, stirred rapidly for 3 minutes, introduced into a mold, and naturally cured for 28 days to obtain a foam concrete block.

Embodiment 3

[0042] A preparation method for lightweight foamed concrete, comprising the steps of:

[0043] Formulated blowing agent

[0044] The components are: 10g of activated sludge protein with a mass concentration of 20%, 0.2g of plant protein with a mass concentration of 40%, 0.1g of sodium dodecylbenzenesulfonate and 87.7g of water are fully mixed to prepare a foaming agent;

[0045] Prepare cement paste;

[0046] The components are: 35g of cement, 30g of fly ash, 5g of lime, 1g of gypsum, 0.5g of polycarboxylate superplasticizer and 28.5g of water, and stir evenly to prepare cement slurry.

[0047] After the foaming agent is foamed, the foam is added to the cement slurry, stirred rapidly for 3 minutes, introduced into a mold, and naturally cured for 28 days to obtain a foam concrete block.

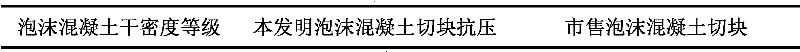

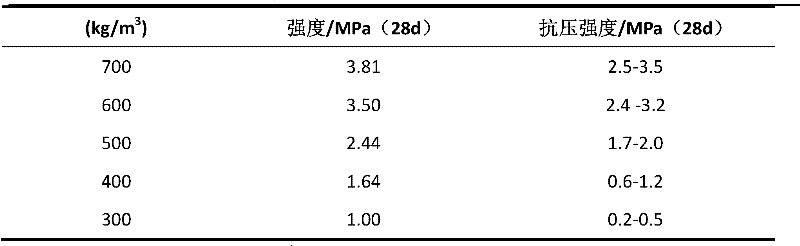

[0048] The performance comparison (seeing table 1, table 2) of foamed concrete and foaming agent prepared by the present invention and commercially available products

[0049] Table 1, foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com