Method for treating high-salinity high-concentration ammonia-nitrogen wastewater

A technology for ammonia nitrogen wastewater and treatment methods, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as inability to efficiently treat high-salt and high-ammonia nitrogen wastewater, and achieve the goal of overcoming inability The effect of treating wastewater resistant to high salt and high ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A treatment method for high-salinity, high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0029] The batch activated sludge method is used to enrich the ammonia nitrogen and salinity of the culture solution step by step. NaCl and KCl are used to simulate high salinity. The initial salt concentration is 5 g / L, and the final salt concentration is 30-35 g / L. L, the initial concentration of ammonia nitrogen is 30-60mg / L, the final concentration is 400-500mg / L, and the concentration of COD is 50mg / L-150mg / L; the enrichment culture of nitrifying bacteria is carried out alternately, and an enrichment culture cycle includes Two stages: the first stage: the cultivation and enrichment of salt-tolerant nitrifying bacteria, the cultivation conditions are: the salt content, calculated as NaCl and KCl, is 5g / L, the concentration of ammonia nitrogen is 30-60mg / L, and the concentration of activated sludge is 20~25g / L, temperature 25~30℃, pH 7~8, DO 4~6mg / L...

Embodiment 2

[0033] Example 2 High-salinity, high-concentration ammonia nitrogen wastewater treatment experiment

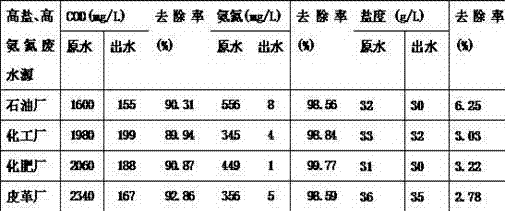

[0034] Get the high-salt, high-ammonia-nitrogen wastewater discharged from petroleum plants, chemical plants, chemical fertilizer plants and tanneries, and inoculate the pollution of salt-resistant and ammonia-nitrogen-resistant high-efficiency nitrifying bacteria obtained by domestication by the method of Embodiment 1 of the present invention into each sewage by 10% volume ratio Processed for 2 days, the specific experimental results are shown in Table 1:

[0035] Table 1 Treatment results of high salinity and high concentration ammonia nitrogen wastewater

[0036]

[0037] Shown by the experimental result of table 1, the present invention adopts intermittent activated sludge process, carries out the enrichment of nitrifying sludge by the method that alternately improves culture solution salinity or ammonia nitrogen concentration, obtains high salt resistance and high ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com