Hollow polymer emulsion capable of forming films at room temperature and preparation method thereof

A technology of polymer emulsion and polymer latex, which is applied in the field of room temperature film-forming hollow polymer emulsion and its preparation, can solve the problems of system stability decline, high glass transition temperature of emulsion polymer, and incapability of self-film formation, etc. The effect of preparation technology and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

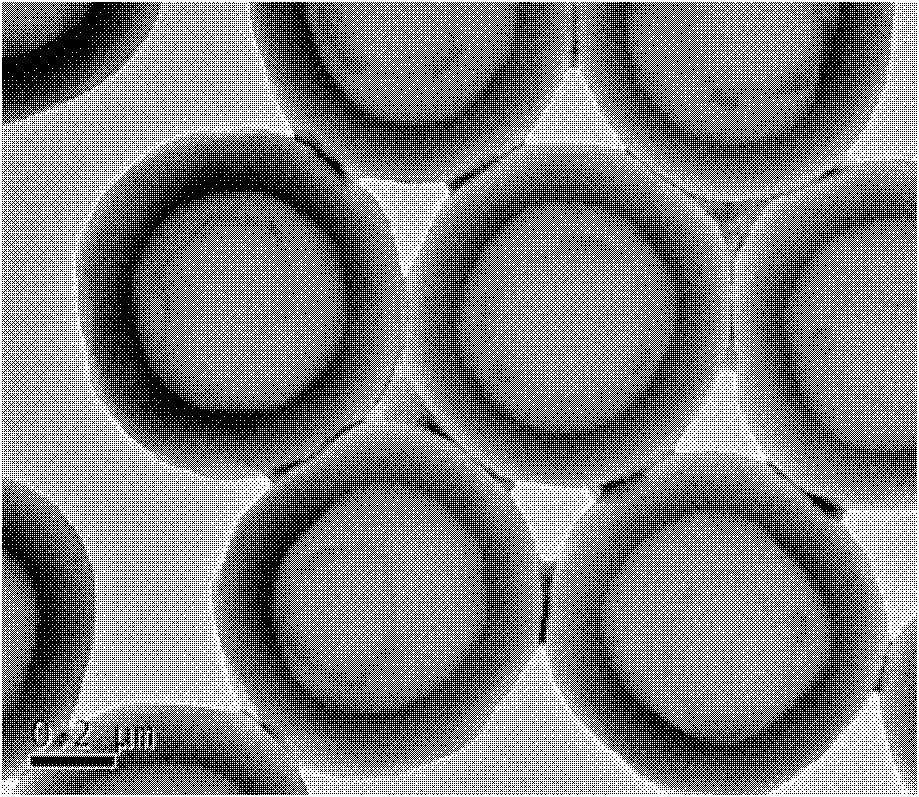

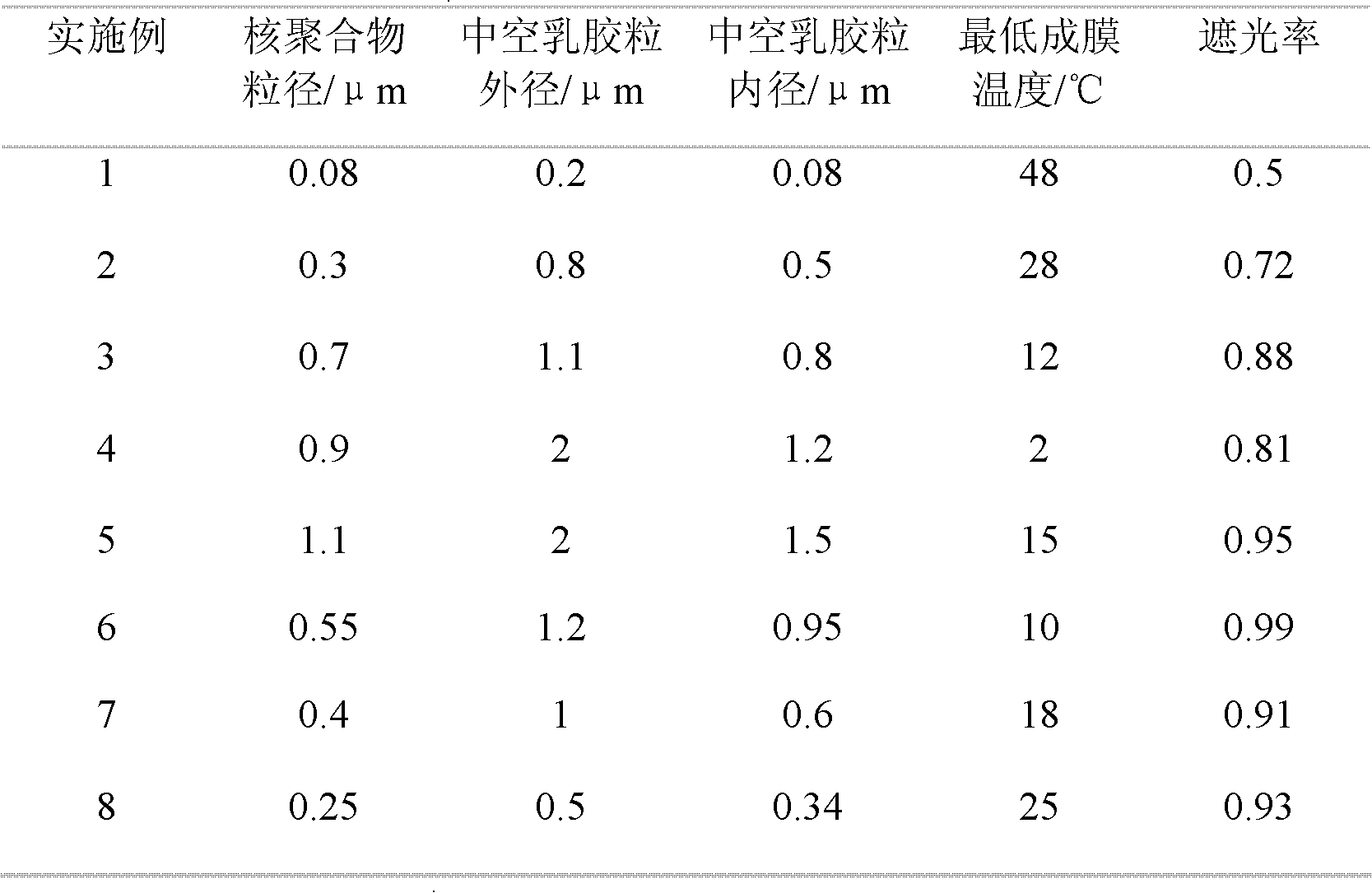

[0041] Embodiment 1, preparation room temperature film-forming hollow polymer emulsion

[0042] (1) Preparation of seed emulsion: 550 grams of deionized water and 0.12 grams of sodium lauryl sulfate were added in a 1-liter four-neck flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet pipe, and the mixture was replaced by nitrogen. Heat to 60°C. A mixture of 17.0 g of methyl methacrylate, 1.6 g of methacrylic acid and 1.4 g of butyl acrylate was added to the flask, and 20 g of a solution containing 0.1 g of potassium persulfate was added thereto. Insulated and stirred for 7 hours to obtain seed emulsion. The seed emulsion has a solid content of 3.3 wt % and an average particle diameter of 0.05 μm.

[0043] (2) Preparation of core polymer: Take 100 grams of the above seed emulsion and add it to a 1-liter four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, dilute with 300 grams of deionized water, and heat to 60° C. Take...

Embodiment 2

[0047] Embodiment 2, preparation room temperature film-forming hollow polymer emulsion

[0048] (1) Preparation of seed emulsion: 550 grams of deionized water and 0.06 grams of sodium lauryl sulfate were added to a 1-liter four-necked flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet pipe, and the mixture was replaced by nitrogen. Heat to 70°C. A mixture of 14.0 g of methyl methacrylate, 1.5 g of methacrylic acid and 2.5 g of butyl acrylate was charged to the flask, and 20 g of a solution containing 0.2 g of potassium persulfate was added thereto. Insulated and stirred for 5 hours to obtain seed emulsion. The seed emulsion has a solid content of 3.1 wt % and an average particle diameter of 0.09 μm.

[0049] (2) Preparation of core polymer: Take 90 grams of the above-mentioned seed emulsion and add it to a 1-liter four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, dilute with 300 grams of deionized water, and heat to...

Embodiment 3

[0053] Embodiment 3, preparation room temperature film-forming hollow polymer emulsion

[0054] (1) Preparation of seed emulsion: 550 grams of deionized water and 0.04 grams of sodium lauryl sulfate were added to a 1-liter four-neck flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet pipe, and the mixture was replaced by nitrogen. Heat to 80°C. A mixture of 16.0 g of methyl methacrylate, 0.7 g of methacrylic acid and 3.3 g of butyl methacrylate was added to the flask, and 20 g of a solution containing 0.3 g of potassium persulfate was added thereto. Insulated and stirred for 3 hours to obtain seed emulsion. The seed emulsion has a solid content of 3.4 wt % and an average particle diameter of 0.14 μm.

[0055] (2) Preparation of core polymer: Take 80 grams of the above-mentioned seed emulsion and add it to a 1-liter four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, dilute with 250 grams of deionized water, and heat to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com