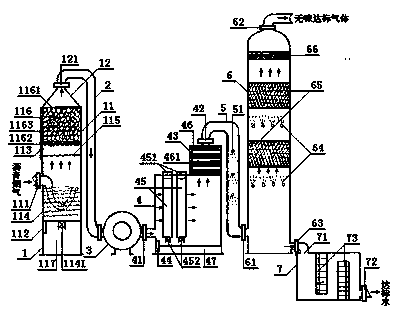

Asphalt fume dust collection and purification system

A technology for collecting asphalt flue gas and dust, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as single function, achieve reliable work, stable performance, and improve the overall treatment effect and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0026]In the accompanying drawings, the asphalt flue gas dust collection and purification system of the present invention, the main body includes a dust treatment tower 1, a gas pipeline 2, an induced draft fan 3 and an oil filter deodorization box 4, and is characterized in that it also includes a main gas spray Pipeline 5, turbulent-flow dynamic wave water film washing tank 6 and sedimentation and oil-repelling circulating water pool 7, wherein: the main body of the dust treatment tower 1 is made of steel plate welding, and the barrel-shaped tower body is provided with an input pipe interface A111 11 and a conical tower top 12 with an output pipe interface A121 on it. The barrel body of the tower body 11 is provided with a control operation door A112 and a cleaning operation door A113. The chamber is sequentially provided with a circular swirl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com