Patents

Literature

36results about How to "Accurate volume control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

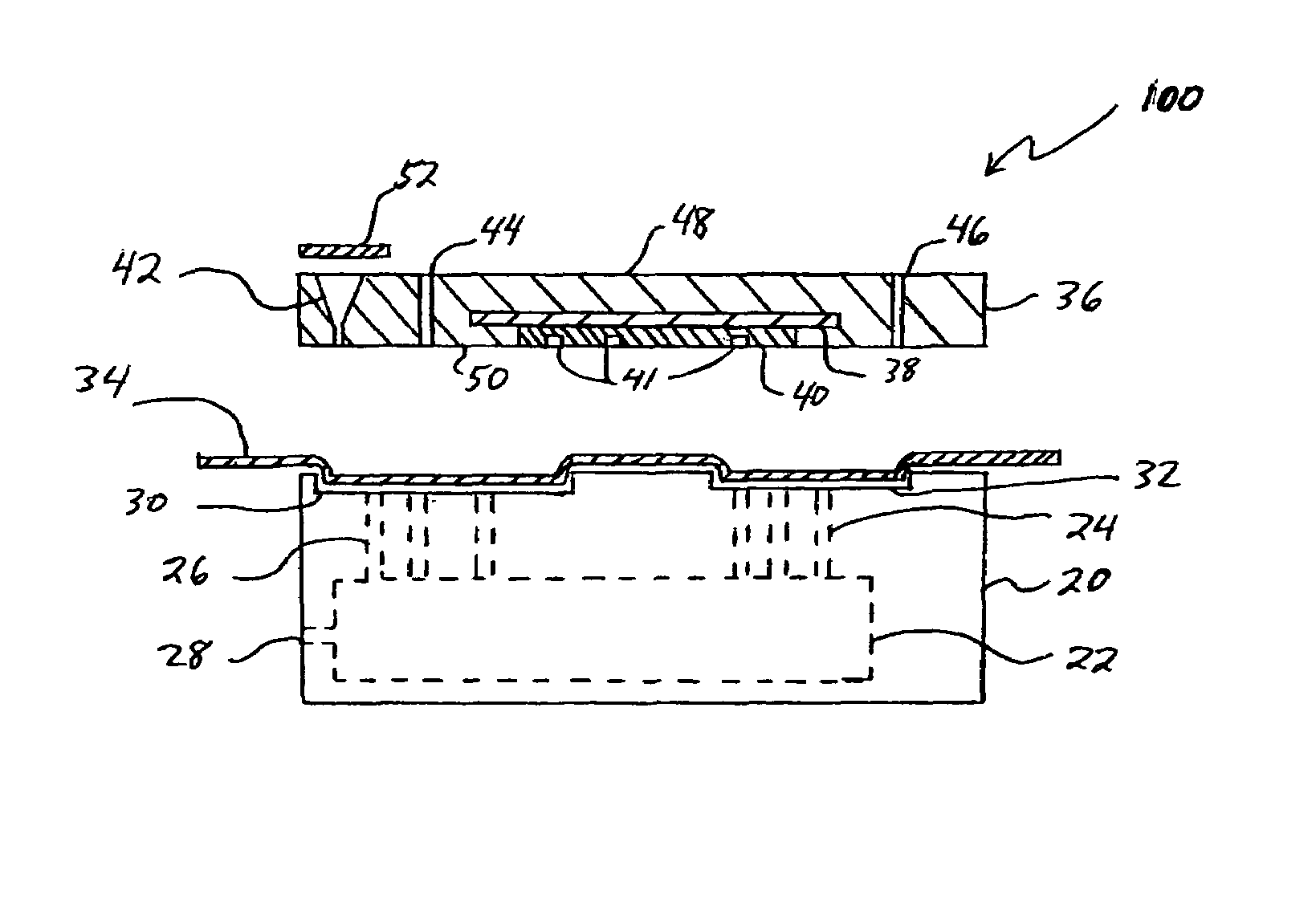

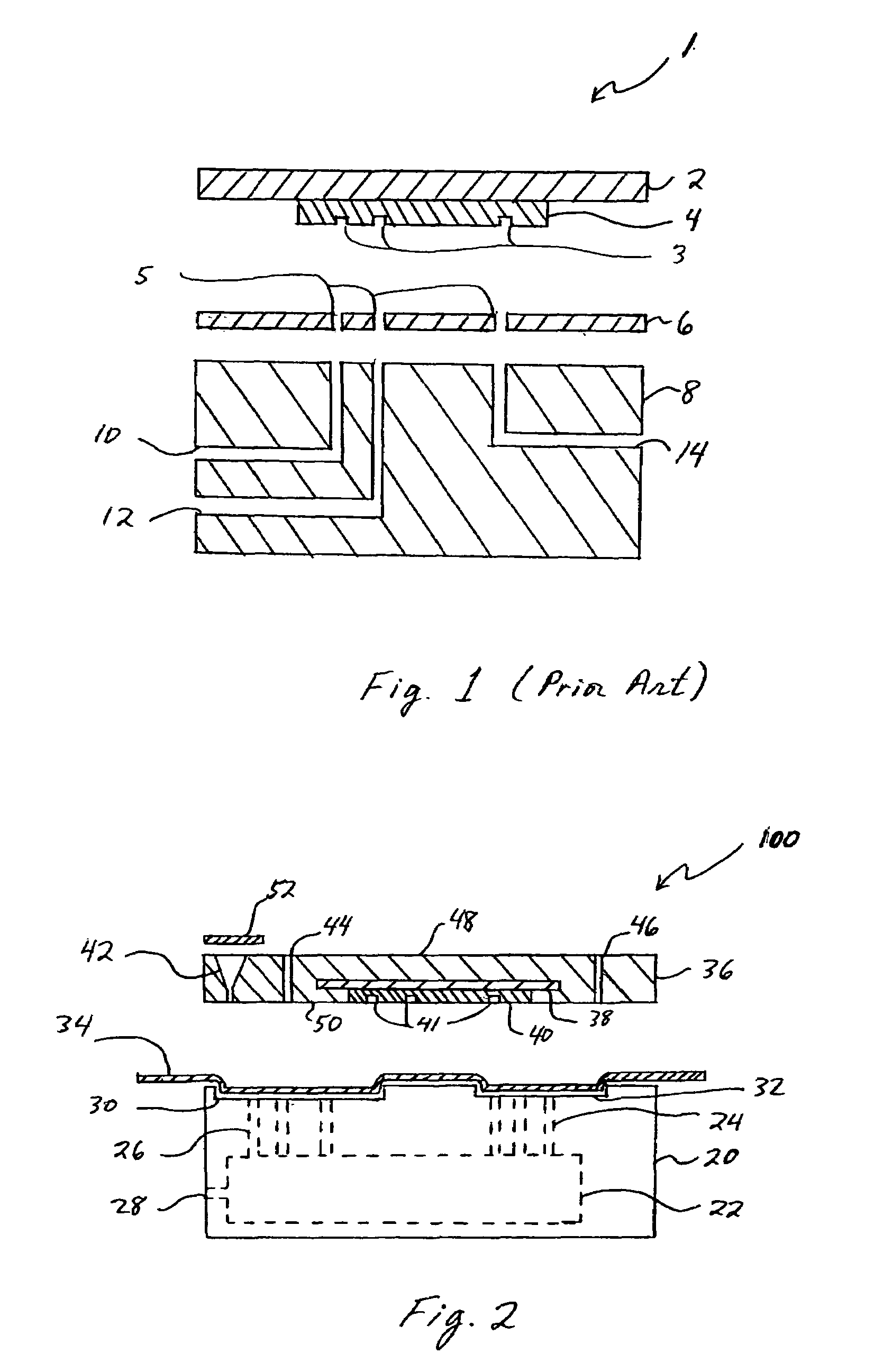

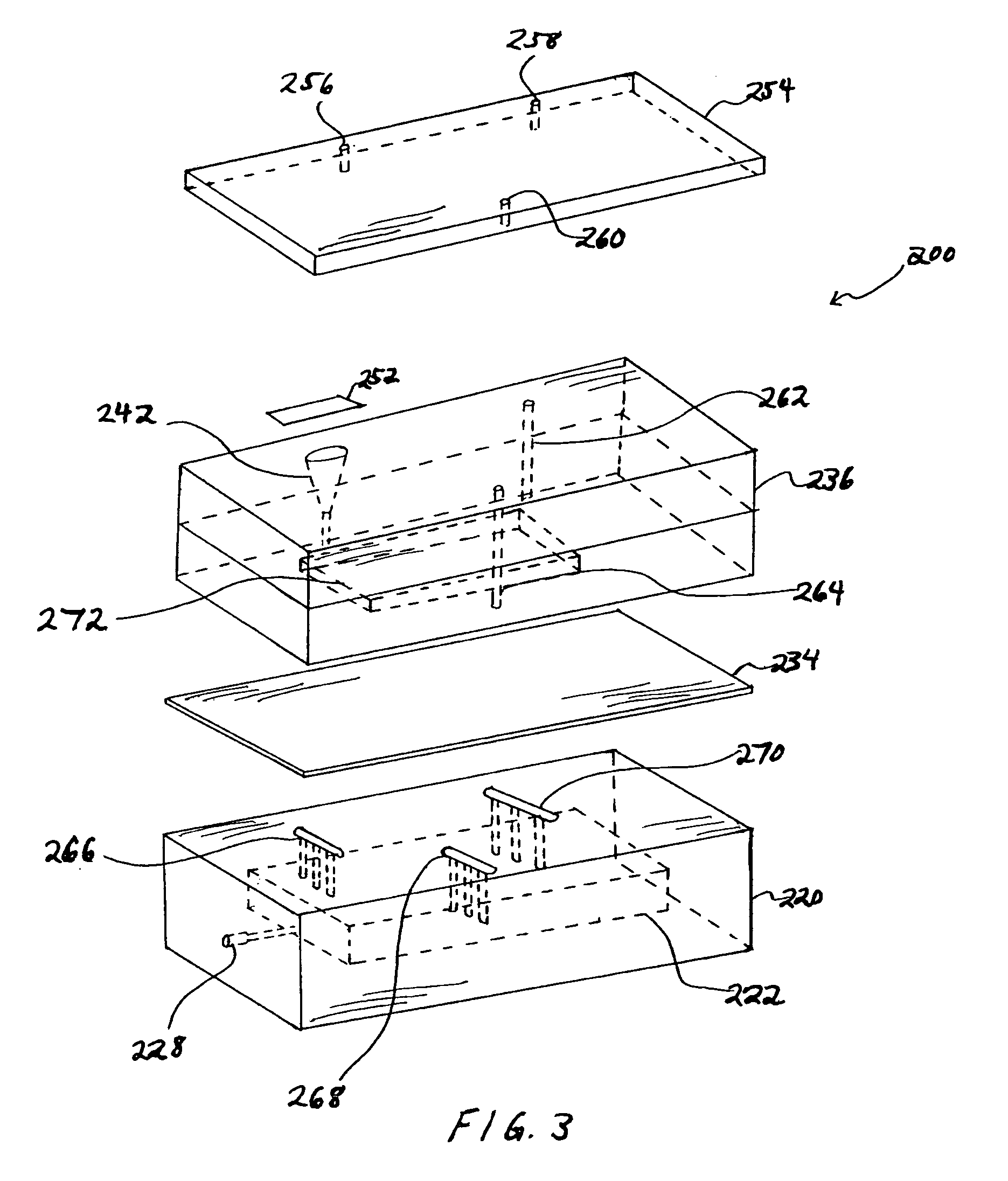

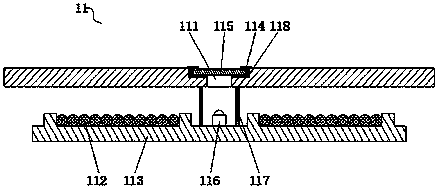

Microfluidics packages and methods of using same

InactiveUS20050026300A1Accurate volume controlReduce dead volumeHeating or cooling apparatusWithdrawing sample devicesFluidicsEngineering

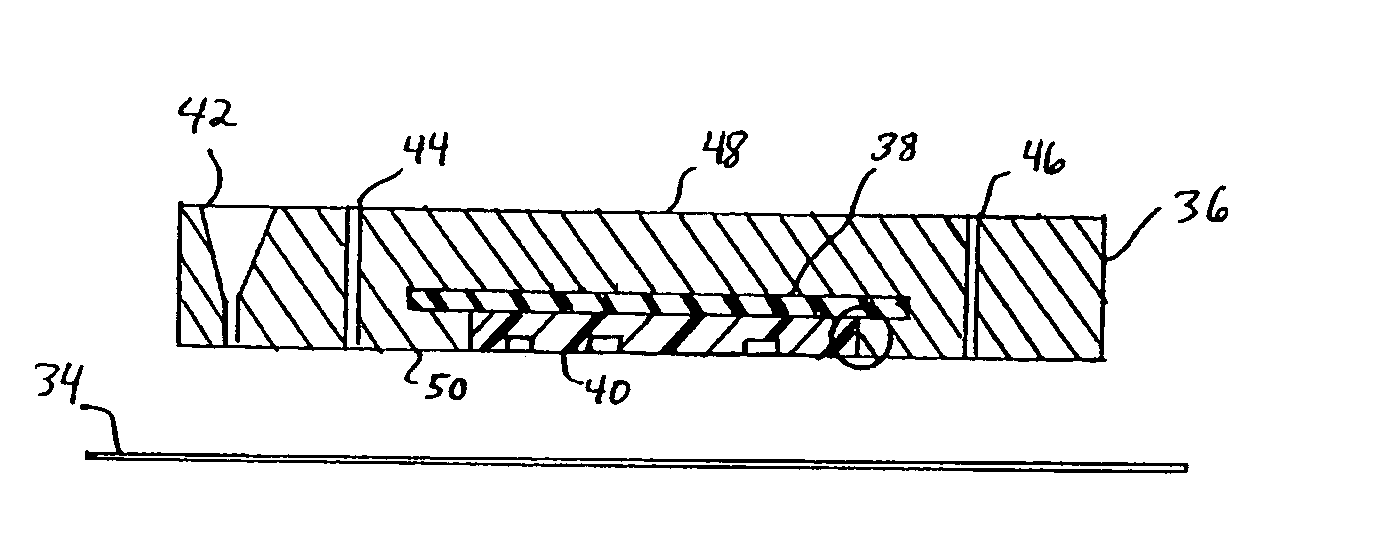

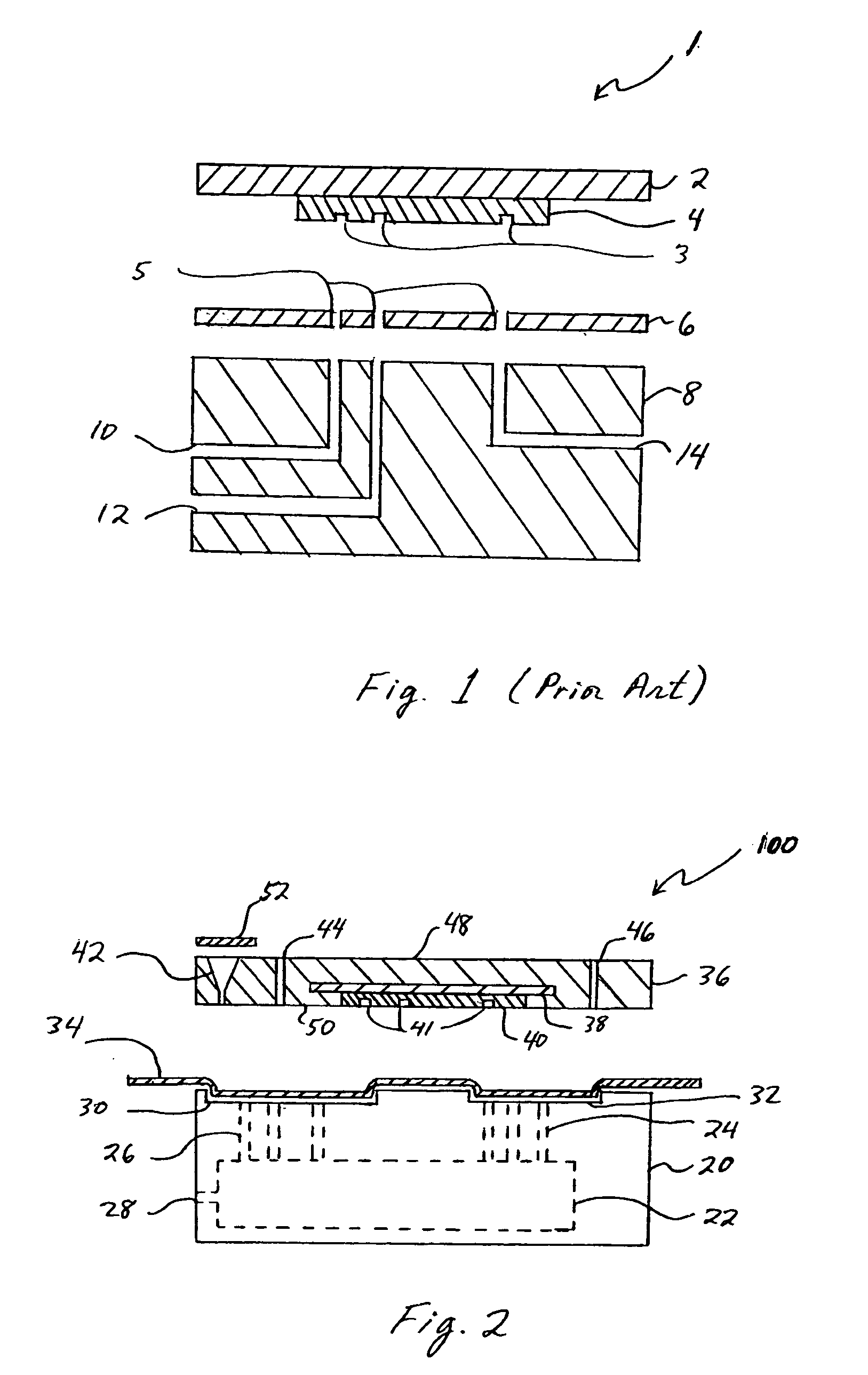

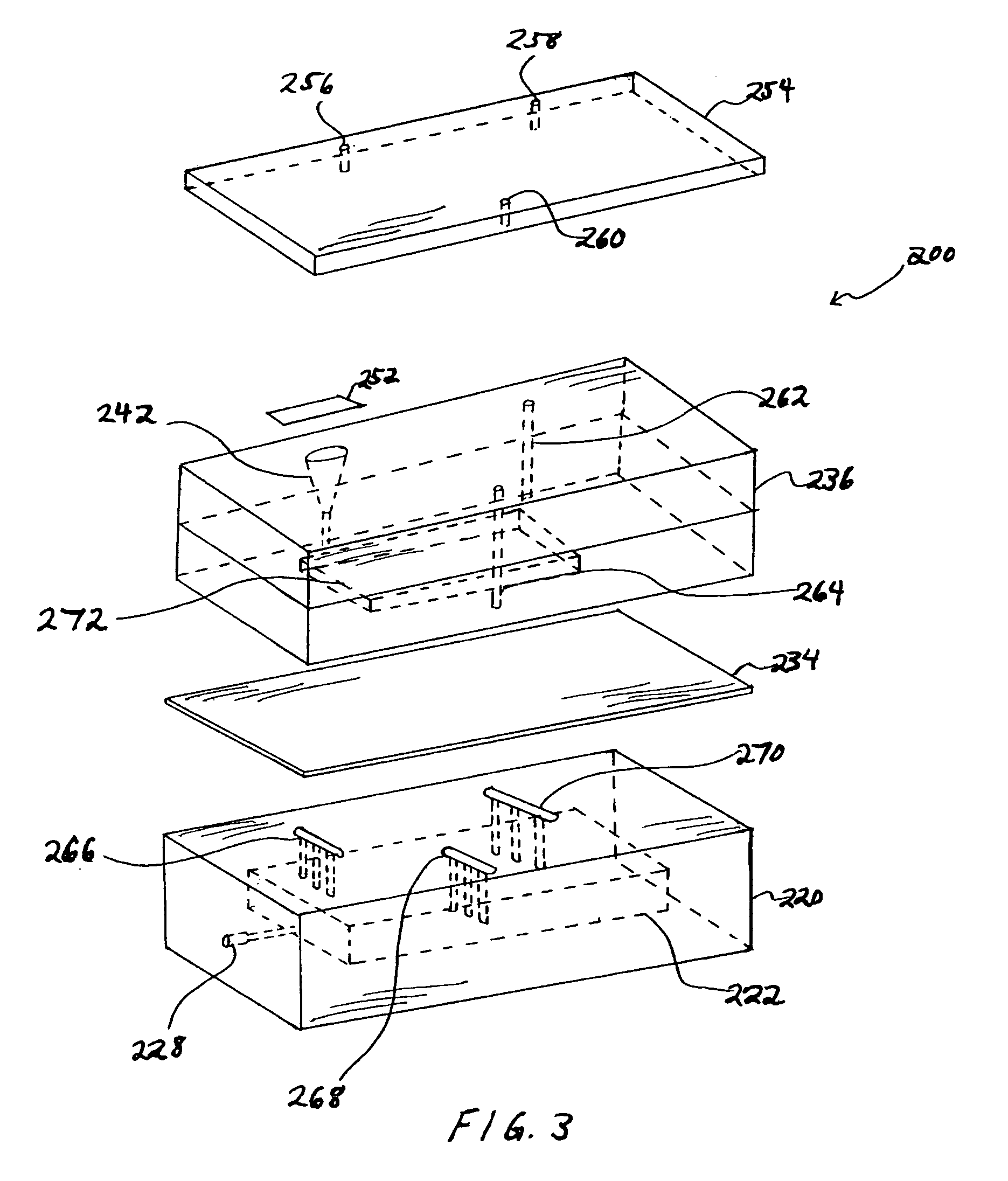

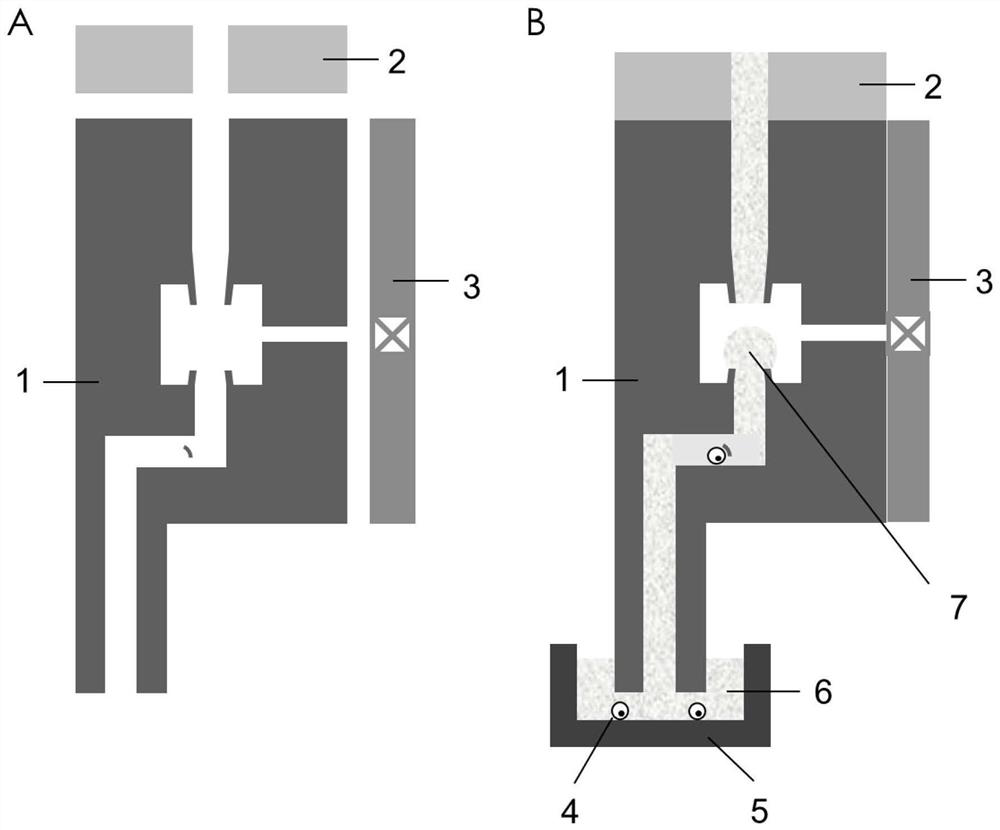

Microfluidics packages and methods of use are described, comprising in one embodiment a substrate having a top surface and means to lower pressure on the top surface; a fluidics card having a bottom surface and means to allow fluids to traverse through the card; and a polymeric barrier film, the polymeric barrier film positioned between the top surface of the substrate and the bottom surface of the fluidics card.

Owner:AGENCY FOR SCI TECH & RES

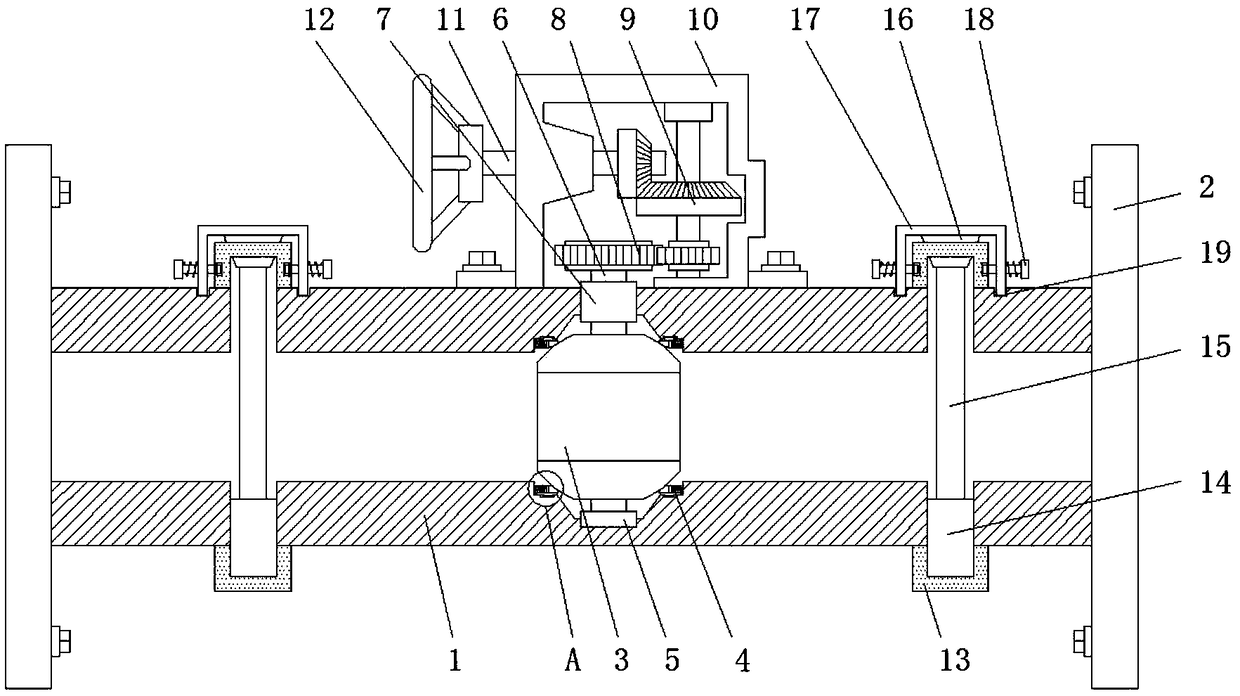

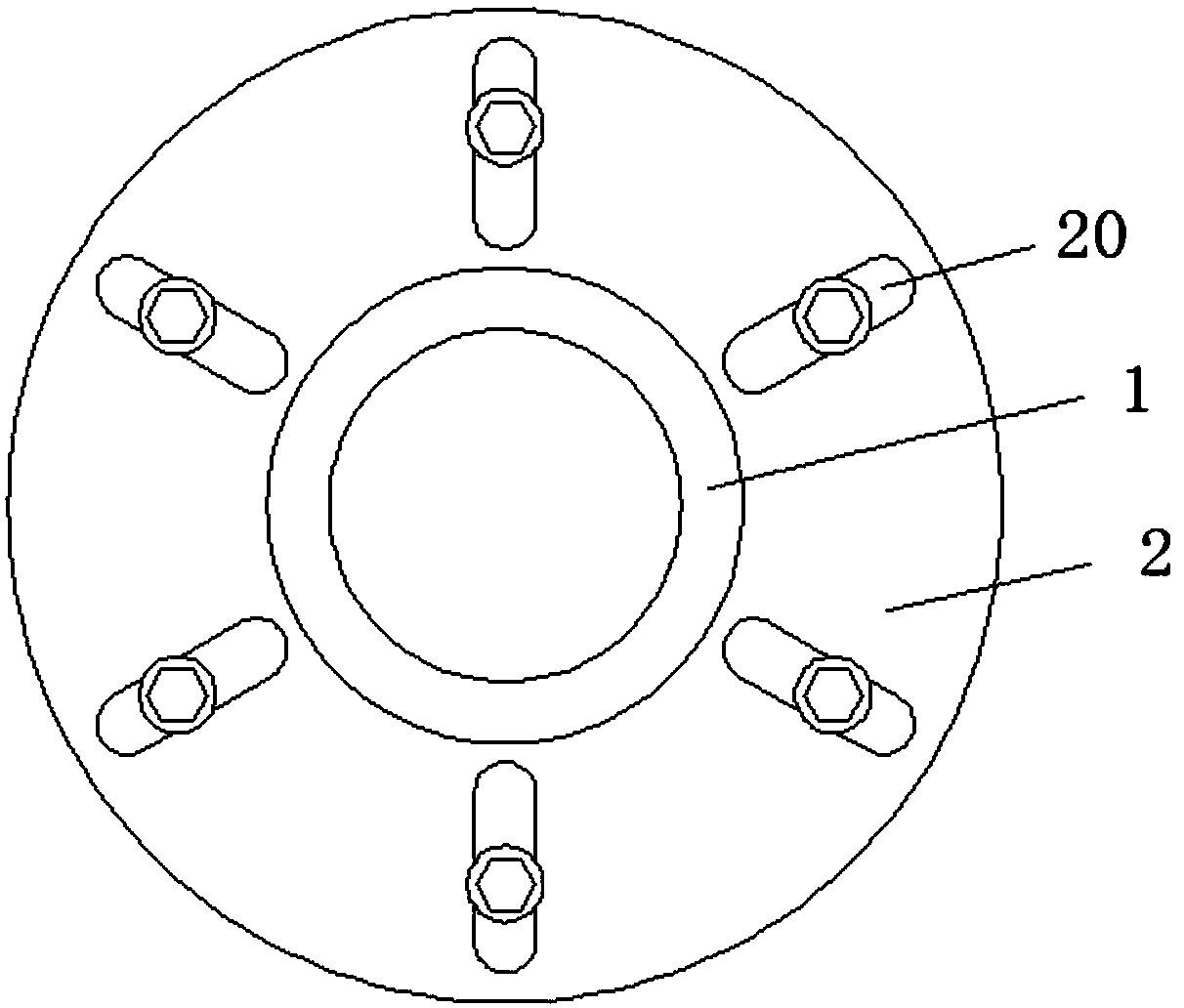

Volume control type sewage pipe connecting valve

InactiveCN108775417AAccurate volume controlHigh rotation accuracyPlug valvesOperating means/releasing devices for valvesGear driveWater flow

The invention relates to the technical field of drainage valves, and discloses a volume control type sewage pipe connecting valve. The volume control type sewage pipe connecting valve comprises a pipebody. Flange plates are fixedly connected to the left and right ends of the pipe body, a ball valve body is fixedly installed on the middle portion of an inner cavity of the pipe body, sealing fasteners are fixedly installed at the junction between the upper and lower outer walls of the ball valve body and the inner wall of the pipe body, the bottom end of the ball valve body is fixedly connectedwith the inner wall of a valve seat bearing in a sleeving mode, the bottom end of the valve seat bearing is fixedly connected with the inner bottom of the pipe body, the top end of the ball valve body is fixedly connected with an upper valve stem, and a valve top bearing is fixedly connected to the outer wall of the upper valve stem in a sleeving mode. According to the volume control type sewagepipe connecting valve, by arranging a gear set, a handle rotates two circles to drive a first bevel gear to rotate one circle, so that a driven gear drives a driving gear to rotate by ninety degrees,that is, the handle rotates two circles to drive the ball valve body to rotate an opening and closing period, so that higher rotation precision is conveniently obtained under the condition of manual rotation, and the control amount of the equipment to the pipeline water flow is more accurately controlled.

Owner:张健

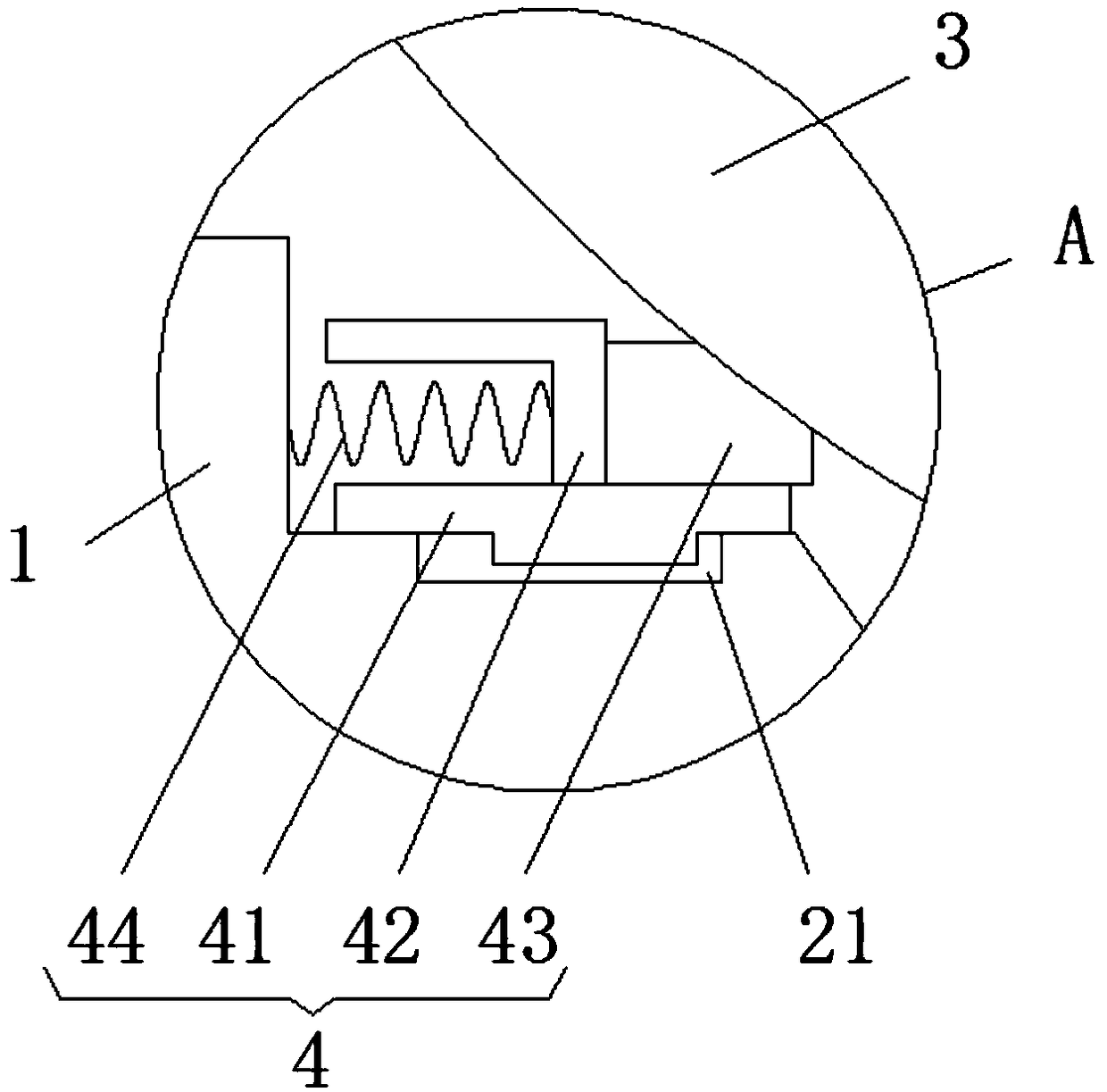

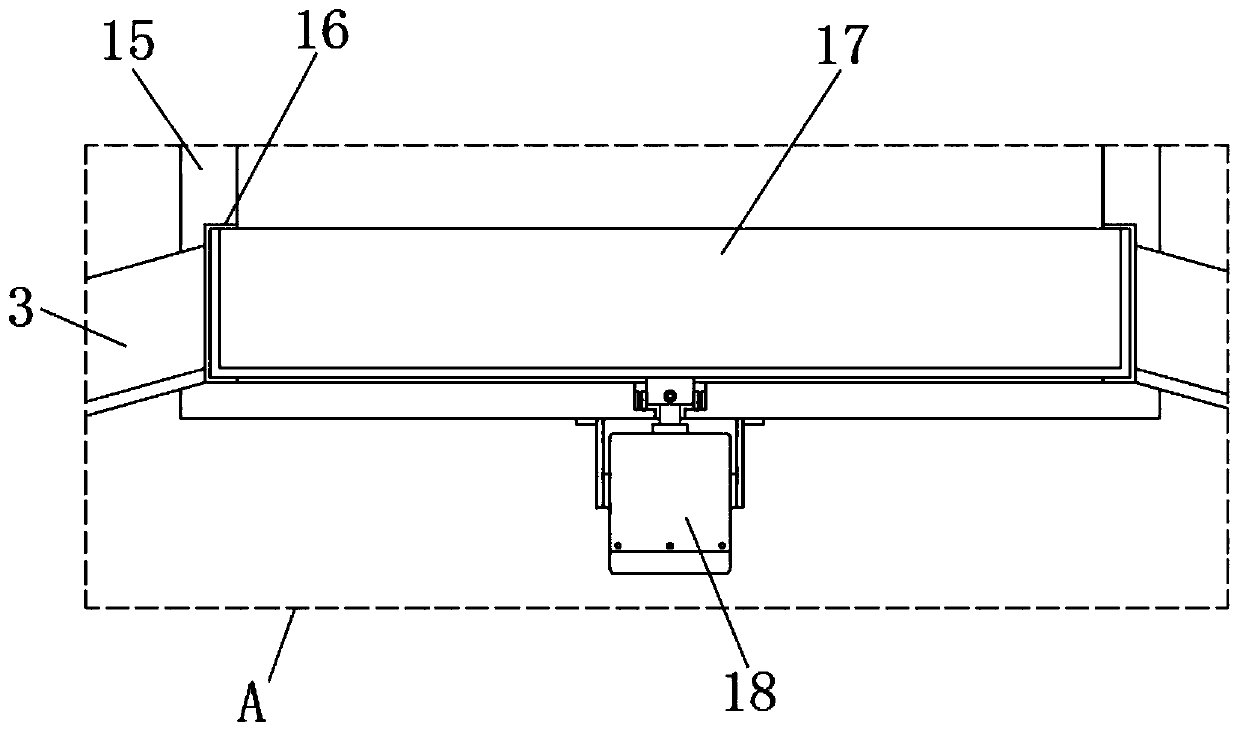

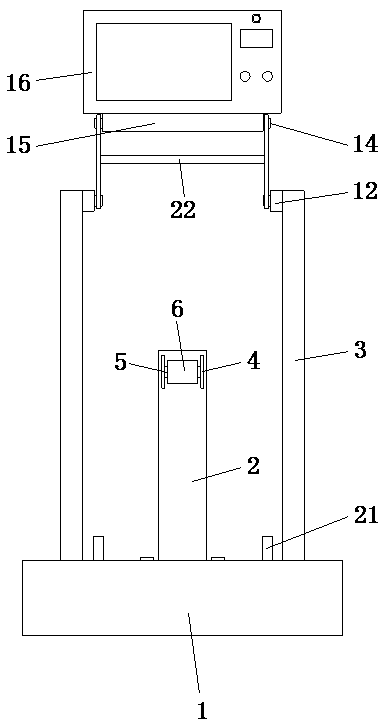

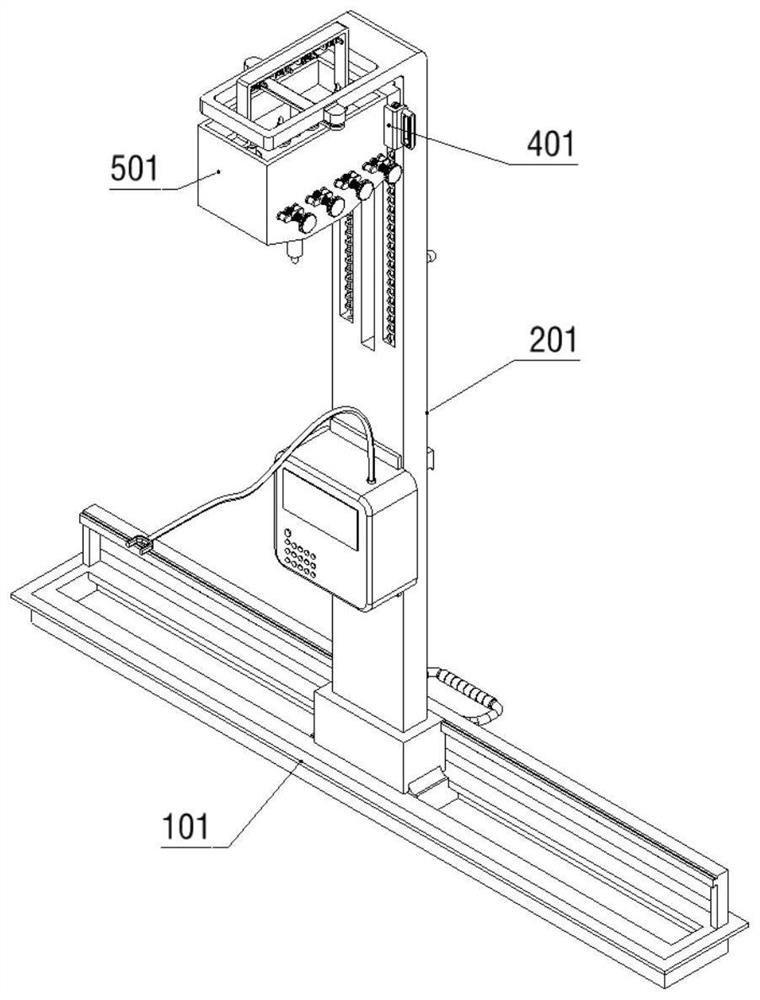

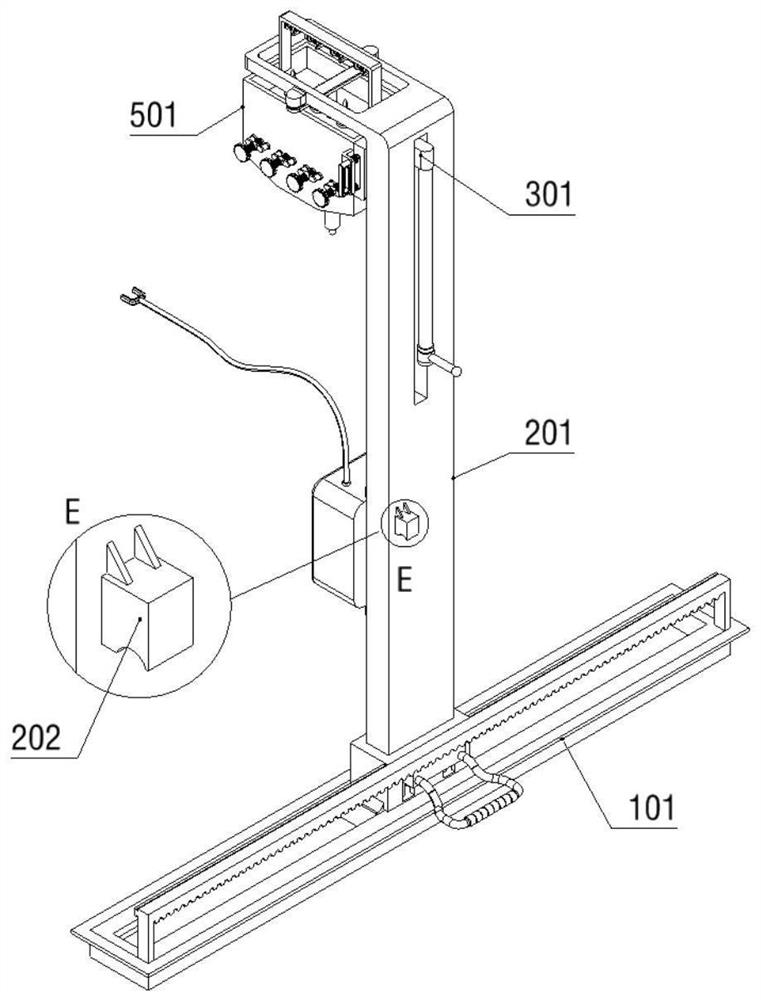

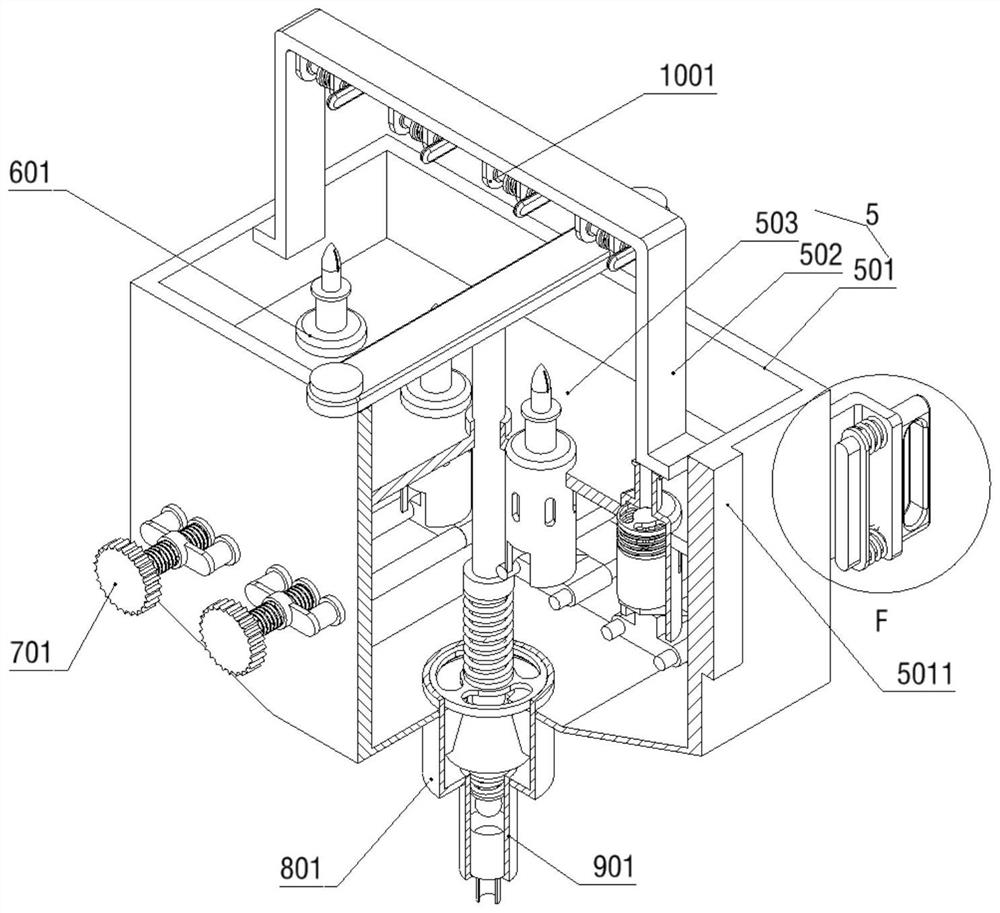

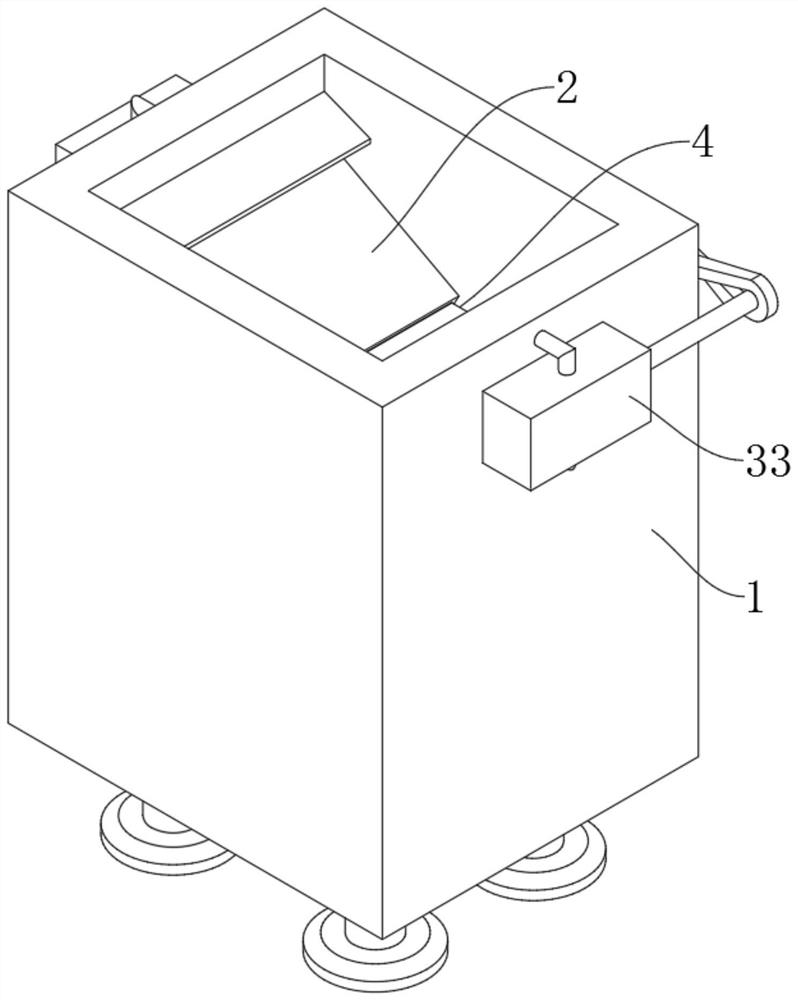

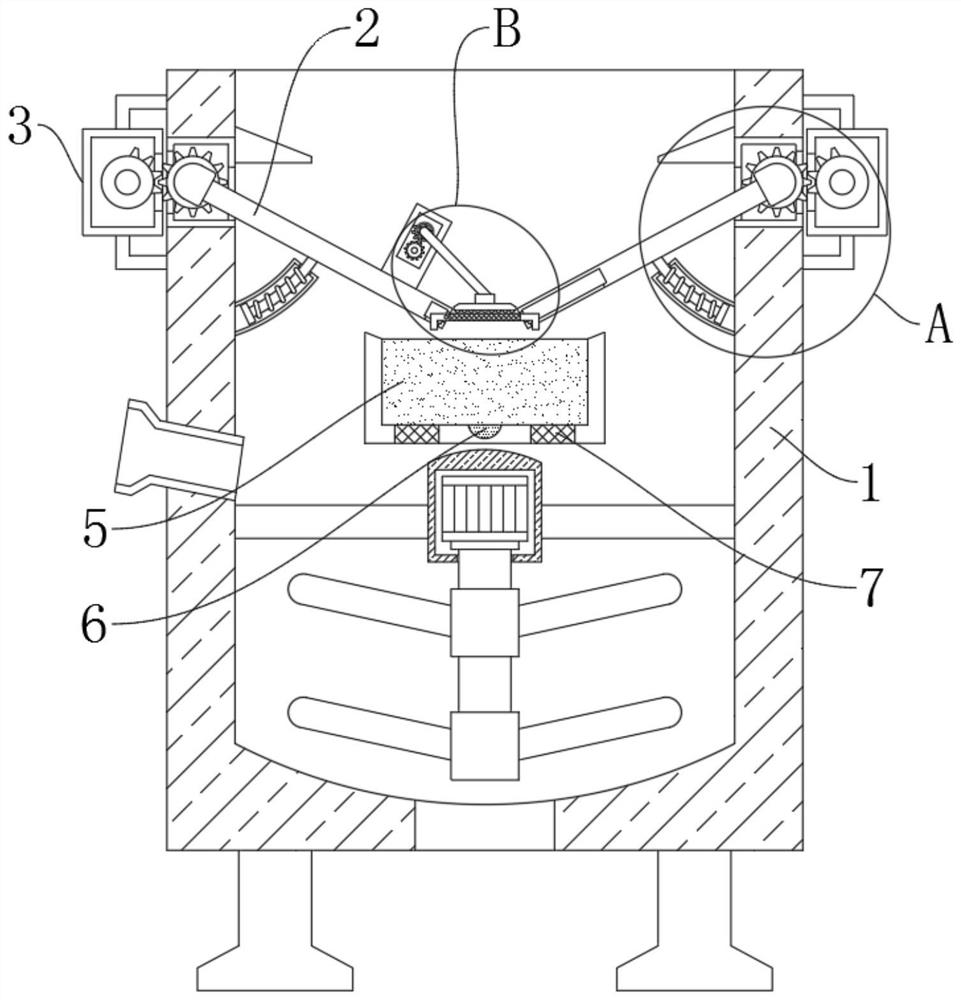

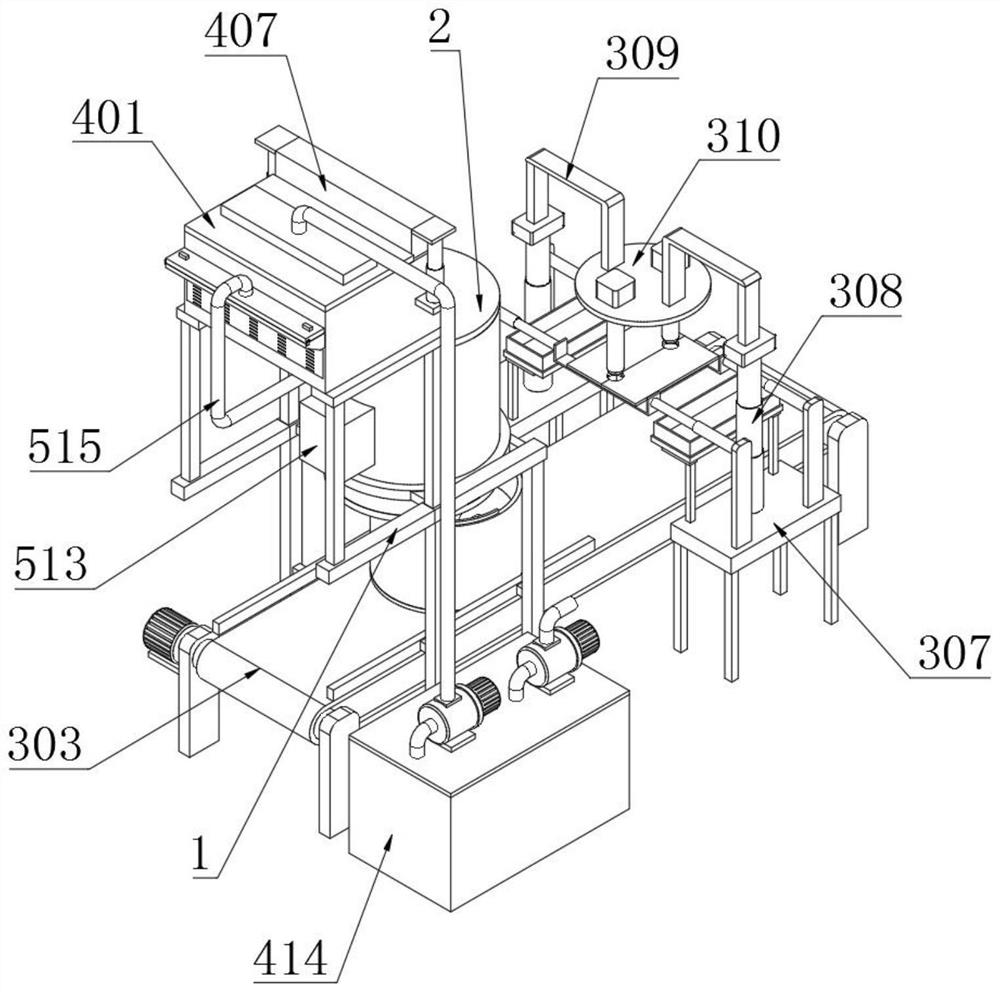

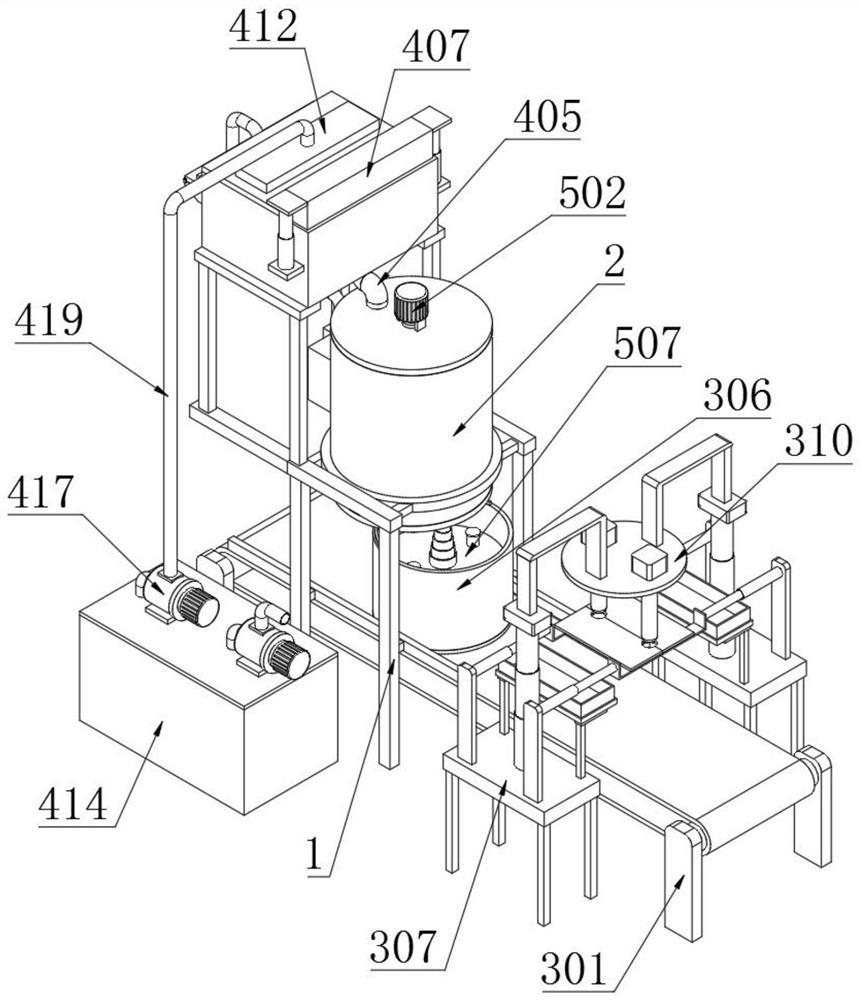

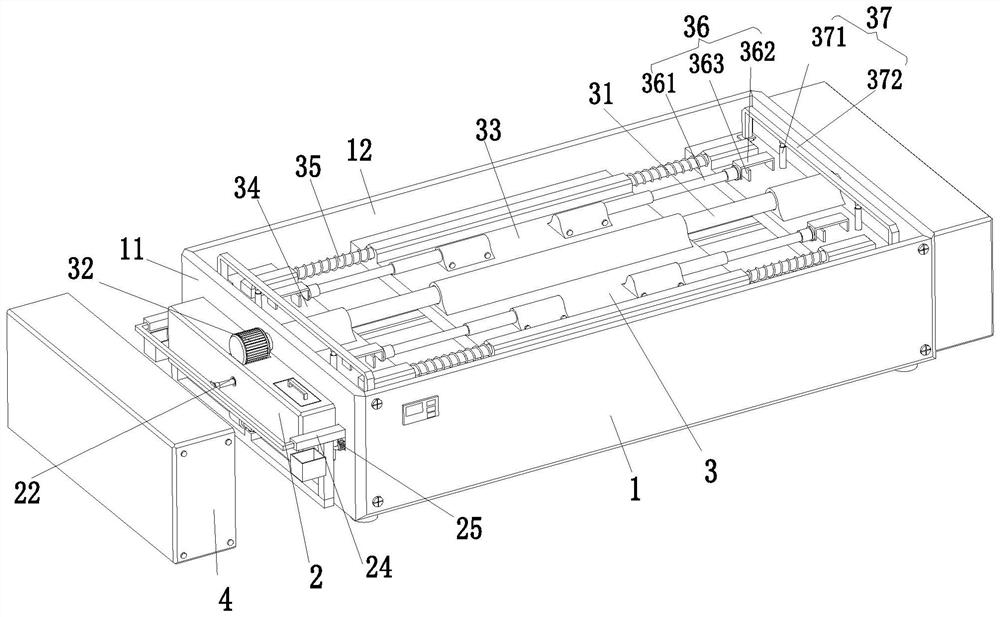

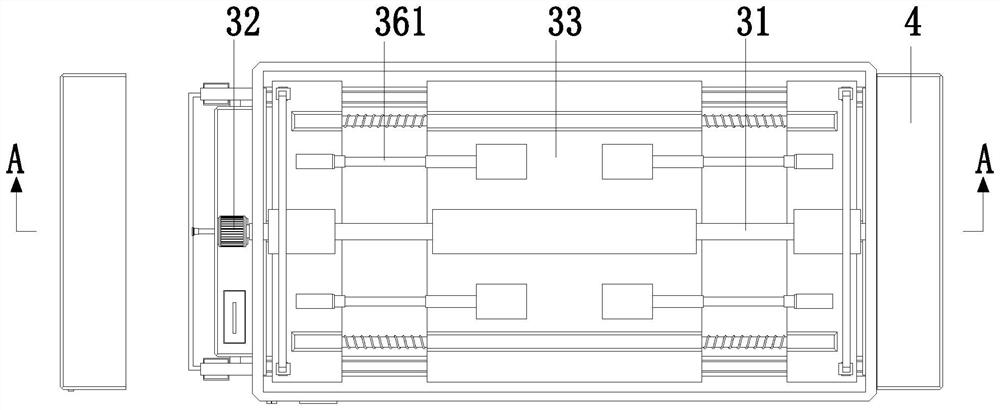

Throwing device capable of achieving automatic proportion-controlled feeding

ActiveCN111214986AAccurate volume controlEasy to operateRotary stirring mixersTransportation and packagingElectric machineryStructural engineering

The invention discloses a throwing device capable of achieving automatic proportion-controlled feeding. The device comprises a base, a gear motor, a junction box and a third stepping motor, wherein amaterial mixing barrel is fixed at the top end of the base through bolts; a material distribution pipe is welded to the lower surface of the material mixing barrel; feeding grooves are uniformly inserted in the outer surface of the material distributing pipe; a sliding groove is formed in the inner wall of the material distributing pipe; a material distributing mechanism is arranged on the inner side of the sliding groove; a second stepping motor is fixed on the lower surface of the material distribution pipe through screws; the output end of the second stepping motor penetrates through the lower surface of the material distribution pipe; a junction box is fixed to the outer surface of the mixing barrel through screws; a proportioning barrel is inserted into the upper surface of the material mixing barrel; an observation window is arranged on the outer surface of the front end of the proportioning barrel in a penetrating mode, and the periphery of the observation window and the proportioning barrel are bonded and fixed; and a quantity control mechanism and a sliding frame are arranged on the upper surface of the base. The feeding proportion can be automatically controlled, accuratequantity control is achieved, operation is easy, and batched feeding is facilitated.

Owner:乐清众晟塑胶有限公司

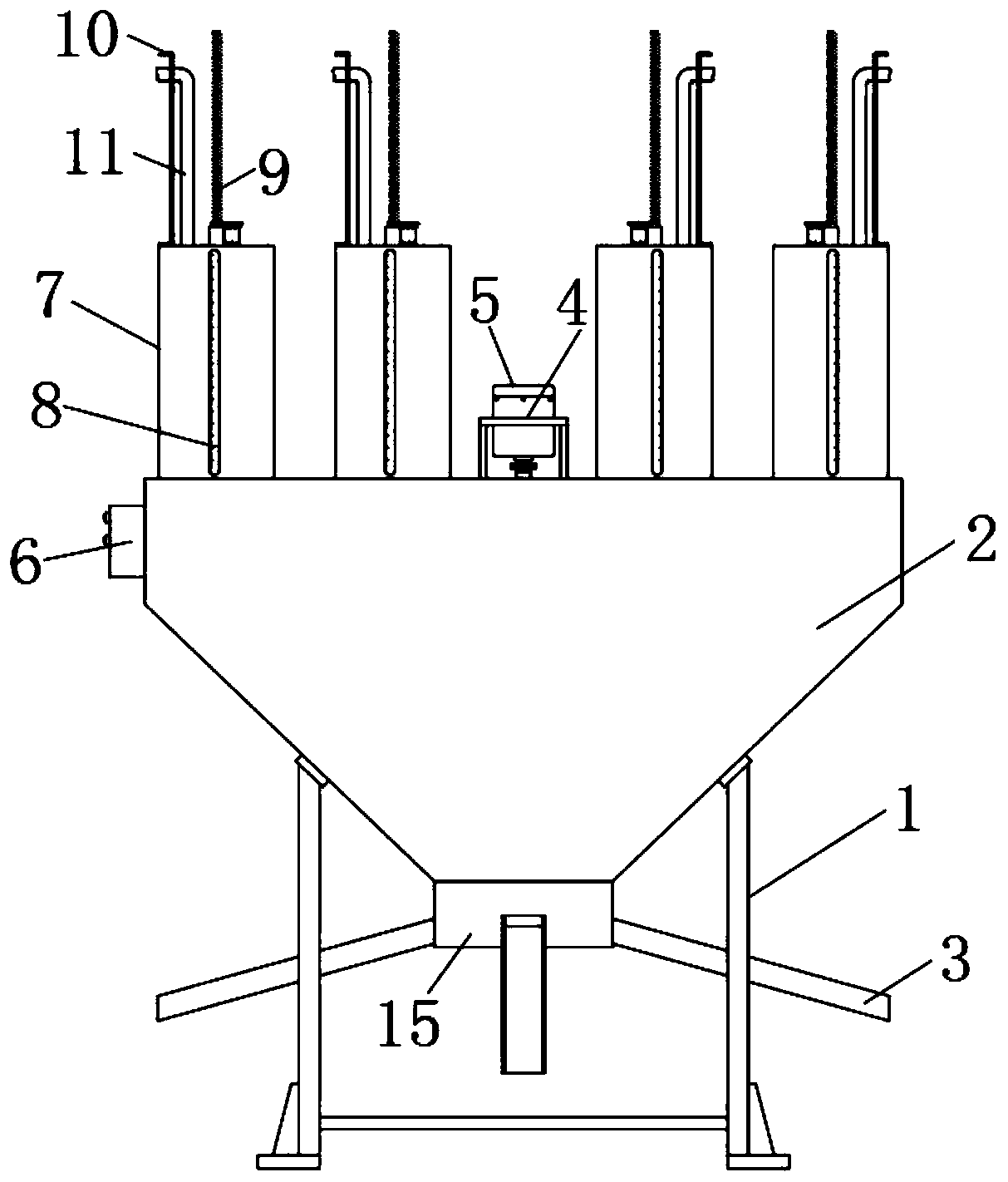

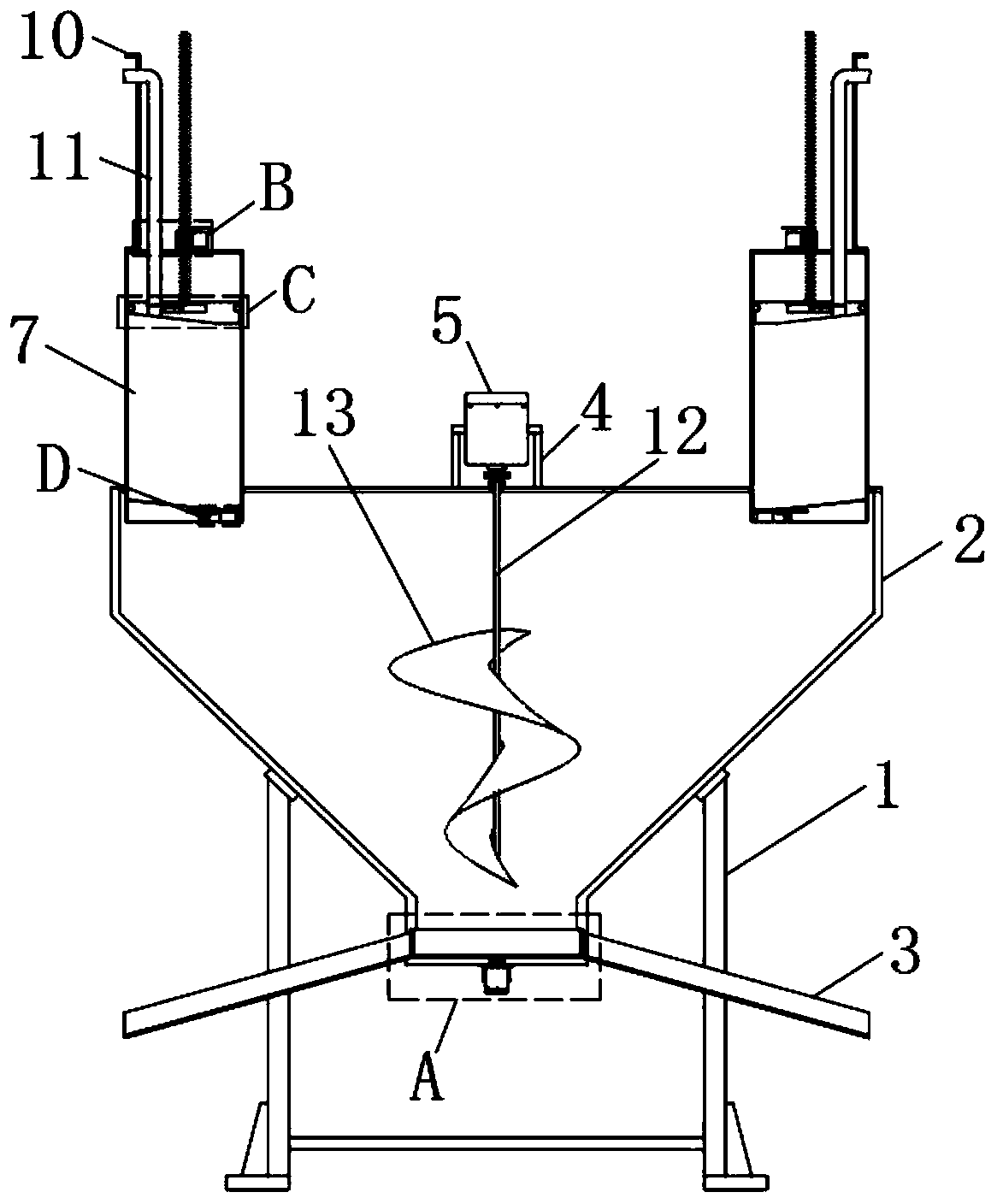

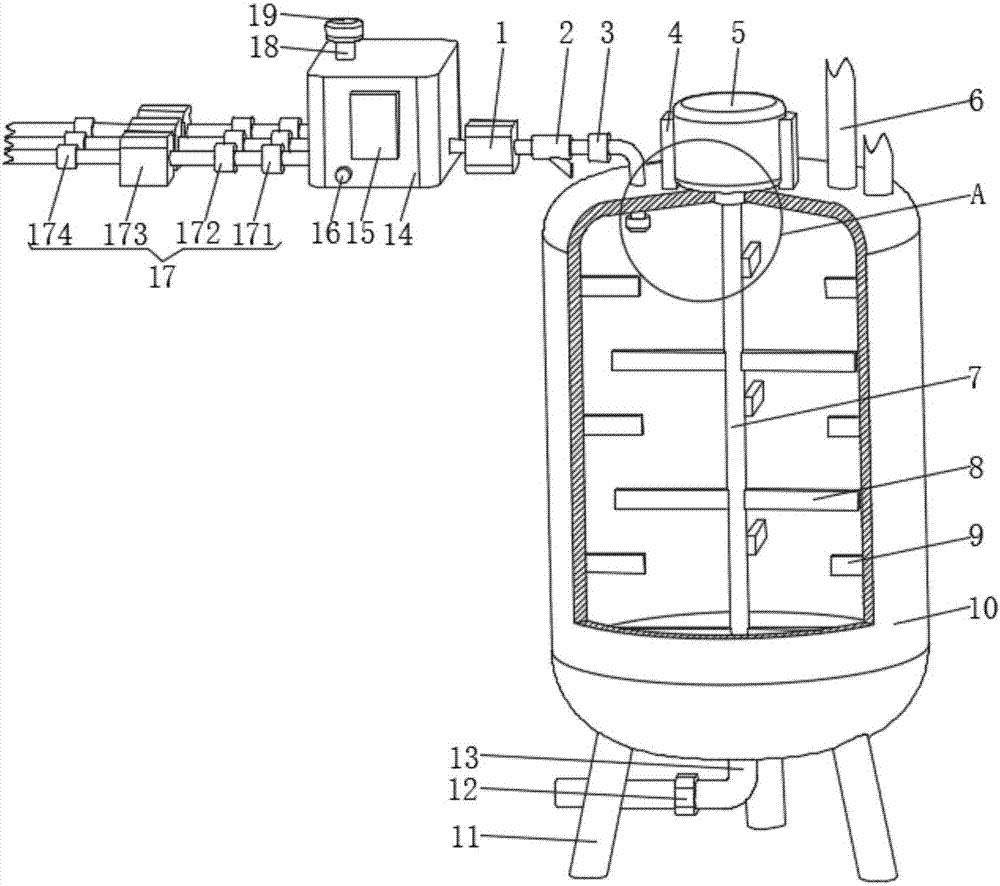

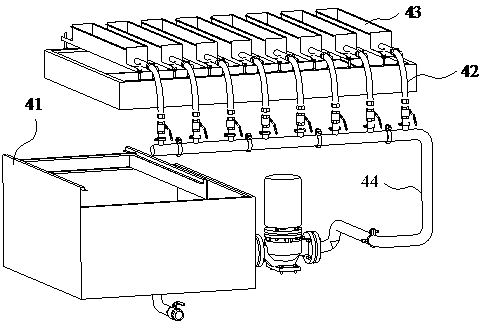

Timed quantitative additive feeding type lubricating oil production equipment

InactiveCN107281951AAccurate timeAccurate volume controlRotary stirring mixersTransportation and packagingOil productionNozzle

The invention discloses timed quantitative additive feeding type lubricating oil production equipment which comprises a shell. A bearing is fixed in a through hole in the middle of the upper surface of the shell, the inner periphery of the bearing is fixedly connected with the lateral upper end of a rotating shaft, the upper end of the rotating shaft is connected with an output shaft of a servo motor through a coupler, the servo motor is fixed to the upper surface of the shell through a mounting frame, and the lower end of the rotating shaft extends into the shell. Stirring blades are fixed to the lateral side of the rotating shaft, and a feeding port in the left side of the upper surface of the shell is communicated with a discharging port of a first electromagnetic control valve through a guide pipe. The timed quantitative additive feeding type lubricating oil production equipment is high in intelligence and accurate in control of additive feeding time and feeding quantity; by fixed blades, layering of lubricating oil in the shell can be prevented during stirring, and efficiency in mixing of lubricating oil and additives is improved; by an atomizing nozzle, uniformity in distribution of the additives is achieved, and the additives can be completely mixed with lubricating oil in the shell.

Owner:闵俞婷

Microfluidics packages and methods of using same

InactiveUS7357898B2Reduce or overcome many deficienciesReduce dead volumeHeating or cooling apparatusWithdrawing sample devicesFluidicsEngineering

Microfluidics packages and methods of use are described, comprising in one embodiment a substrate having a top surface and means to lower pressure on the top surface; a fluidics card having a bottom surface and means to allow fluids to traverse through the card; and a polymeric barrier film, the polymeric barrier film positioned between the top surface of the substrate and the bottom surface of the fluidics card.

Owner:AGENCY FOR SCI TECH & RES

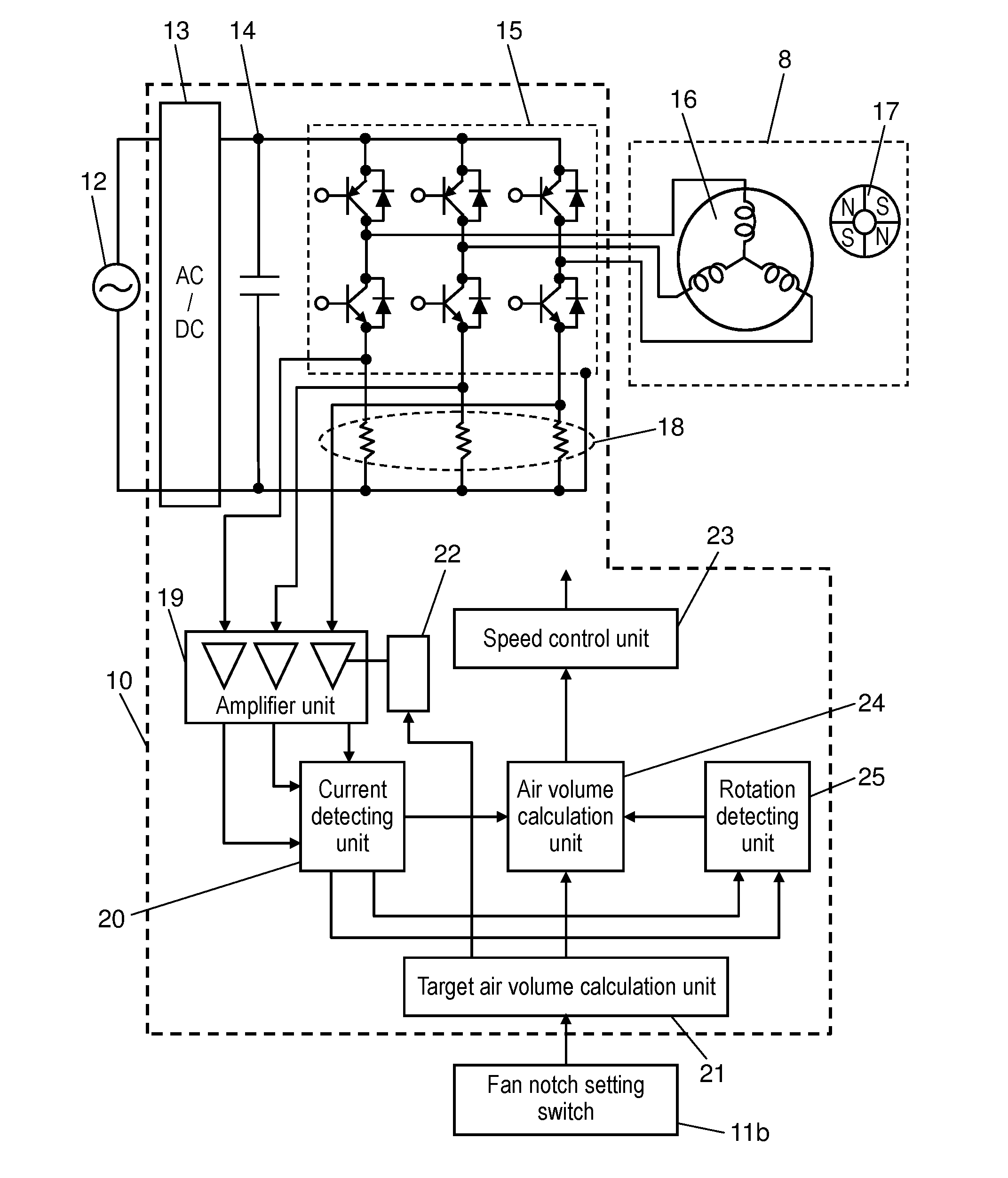

Ventilation device

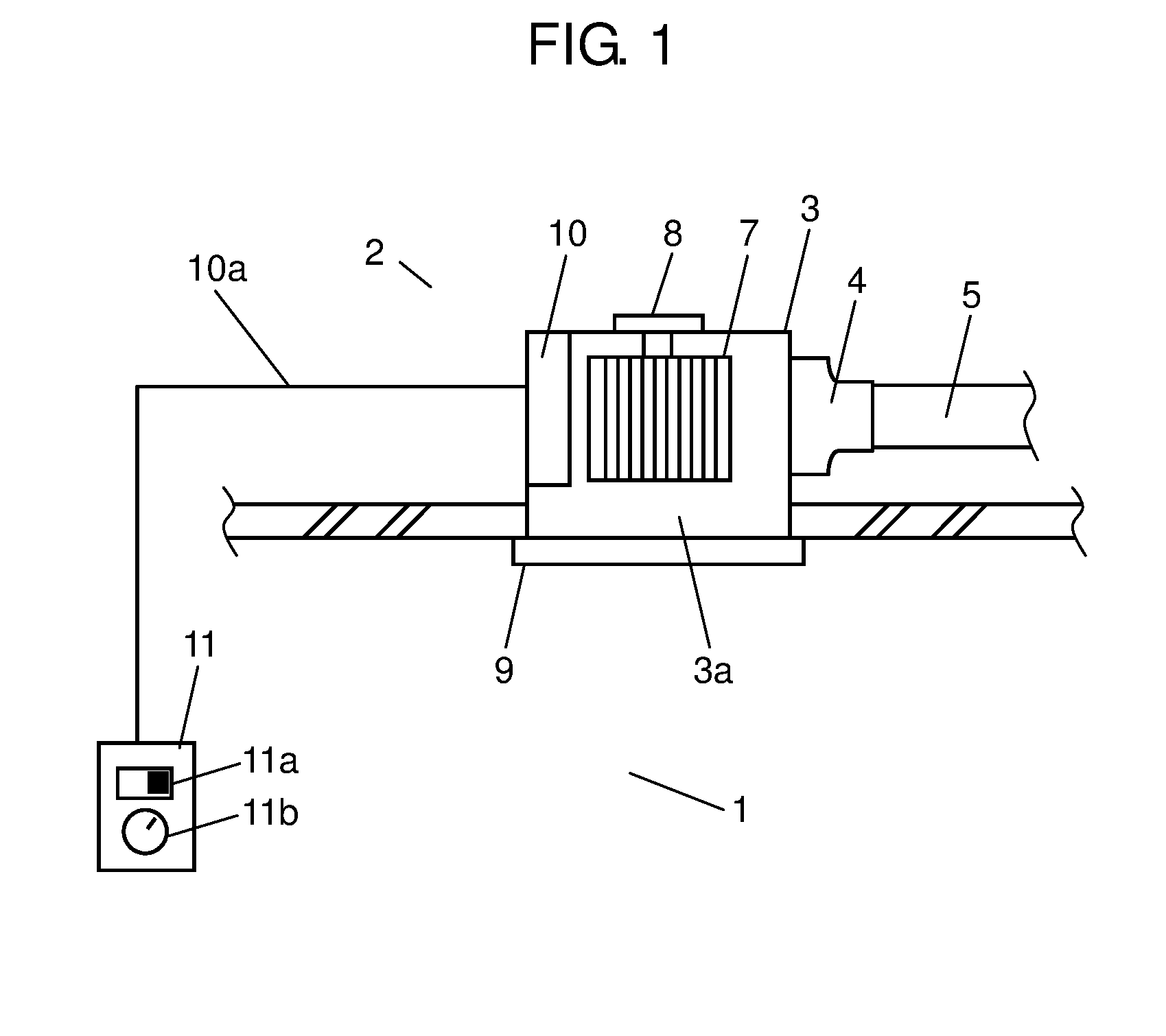

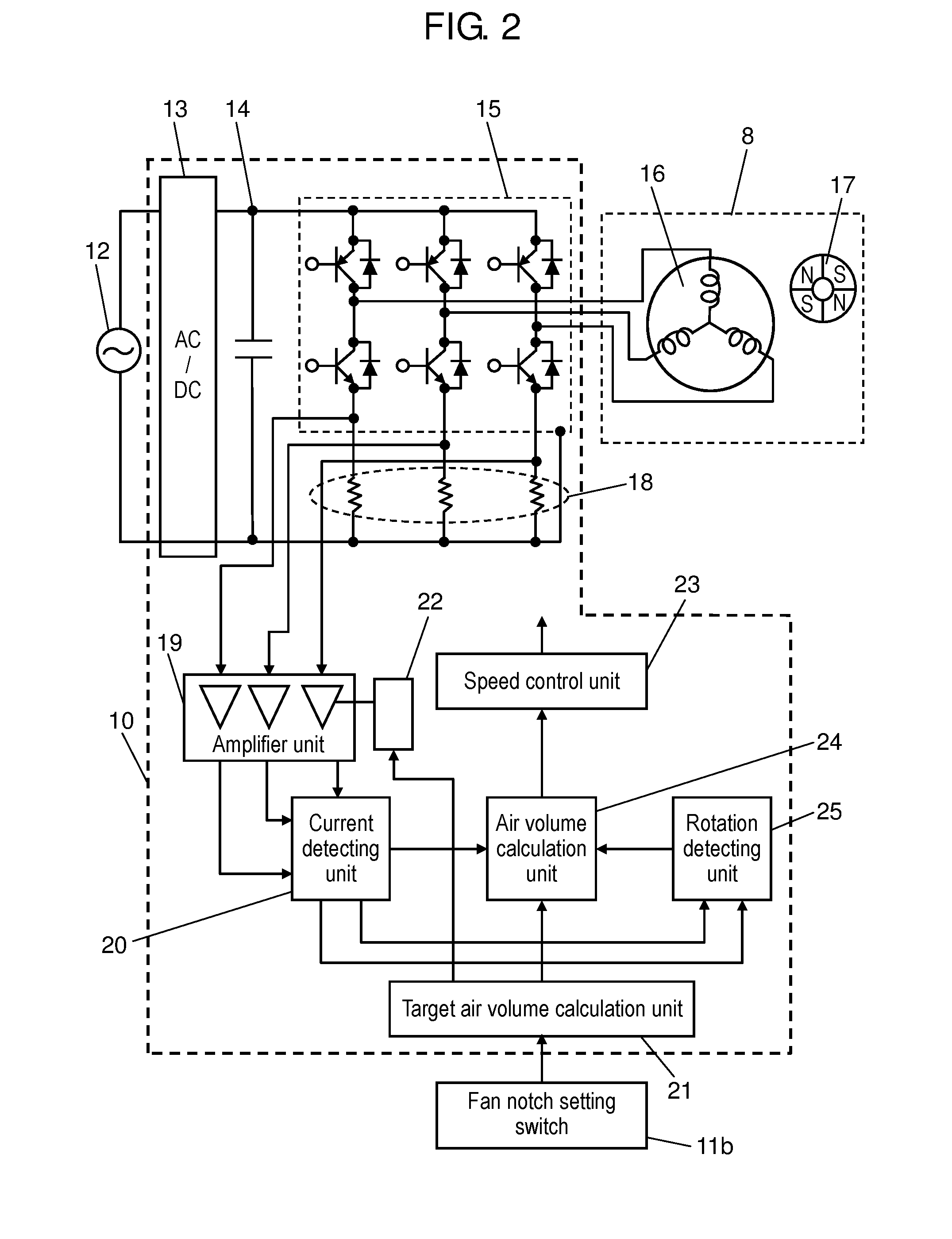

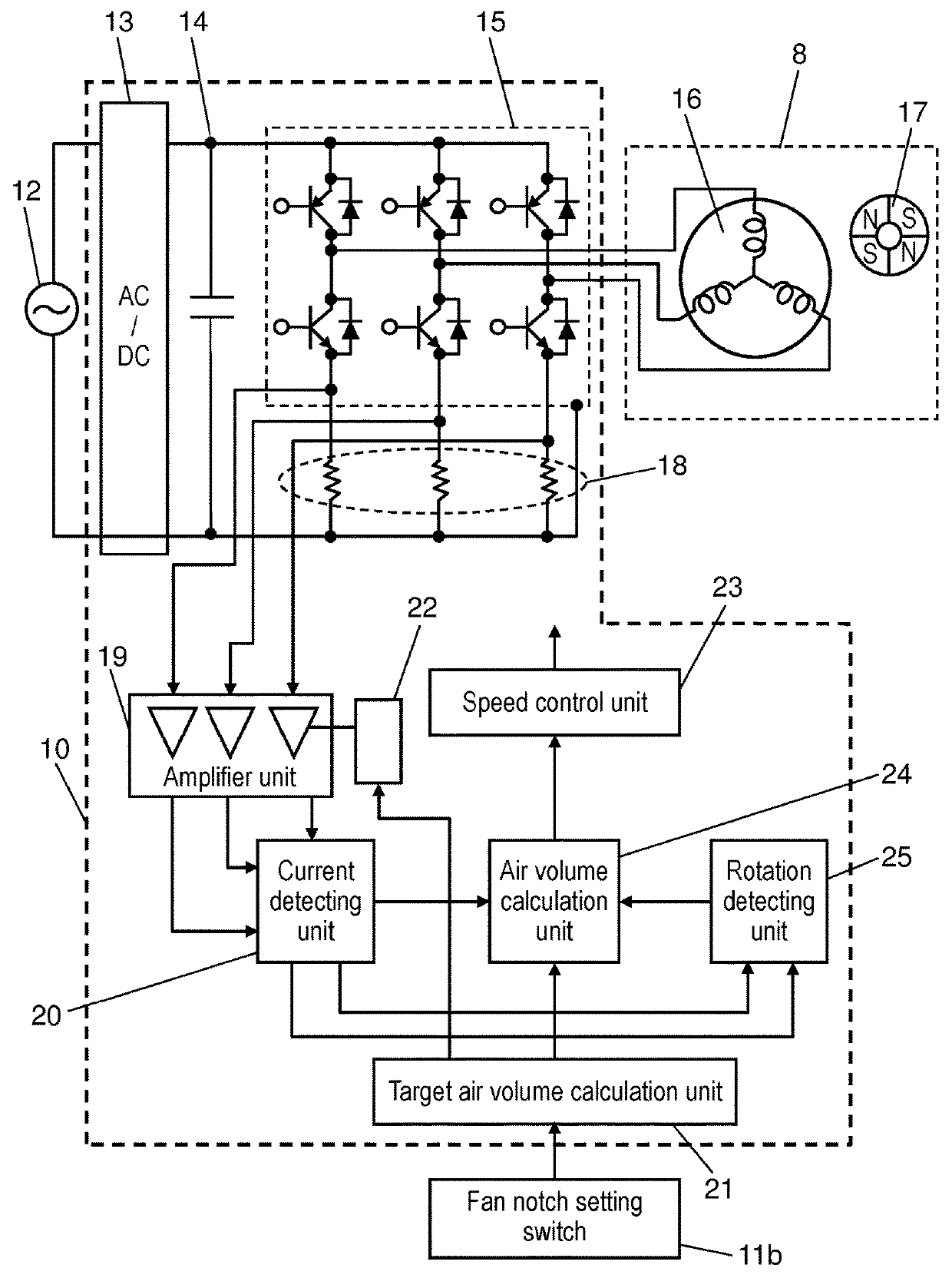

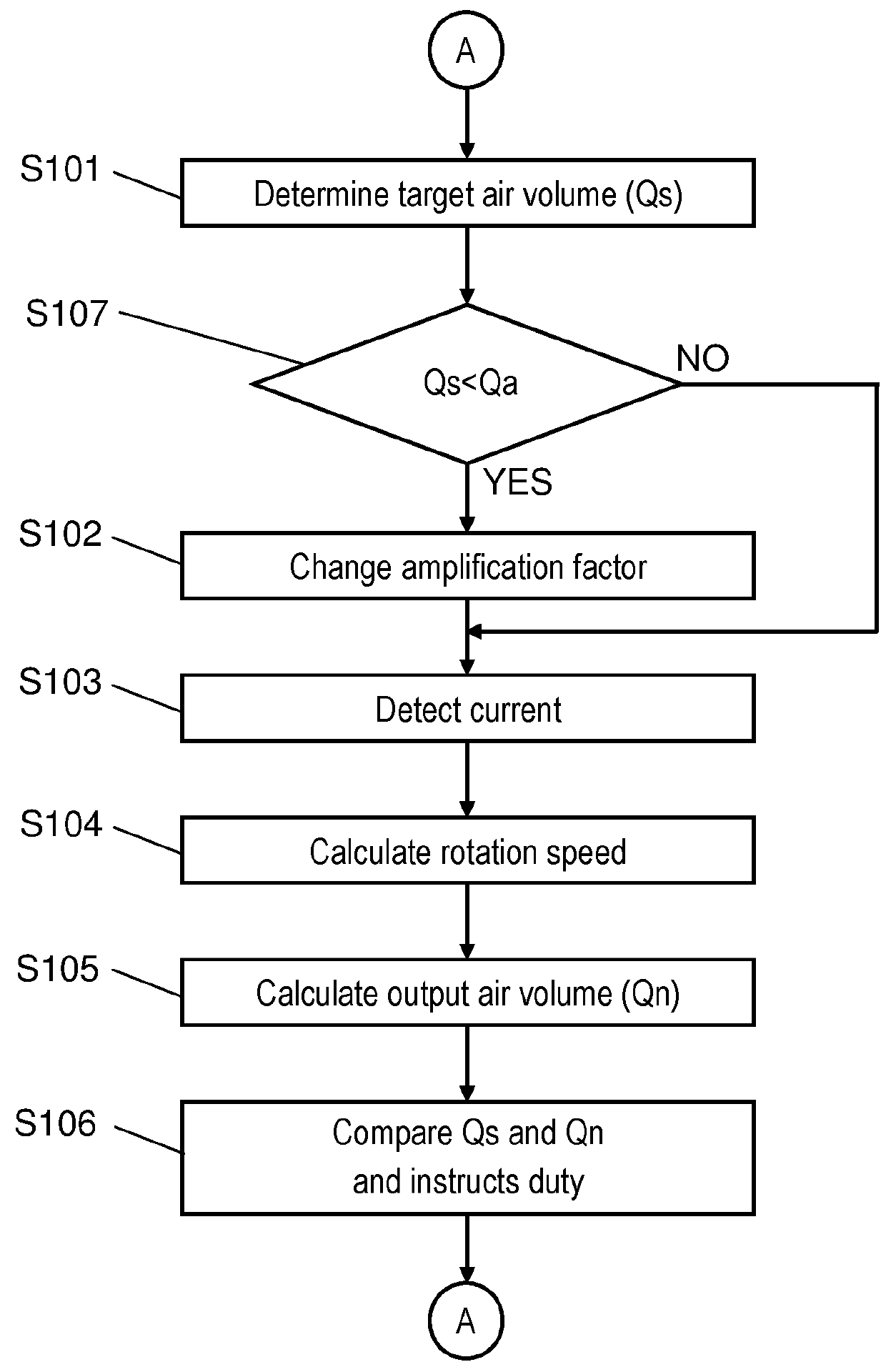

ActiveUS20160131142A1Accurate detectionSuppressing wasteful energyEfficient regulation technologiesPump controlAir volumeEngineering

Between the lower stage in respective phases of inverter circuit and the negative potential side, shunt resistors are inserted for respective phases. The potential differences across shunt resistors occurring by current flowing through shunt resistors are amplified by amplifier unit. From the output of amplifier unit, current detecting unit detects current of each phase flowing through motor formed by a sensorless brushless DC motor. Rotation detecting unit calculates the rotation speed and position of motor based on the current detected by current detecting unit. This structure makes it possible to directly detect solely the current flowing through the windings of motor. Therefore, it becomes possible to accurately detect the current of the motor windings, and the ventilation device can maintain the ventilation air volume from a small air volume to a large air volume always at a constant value.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

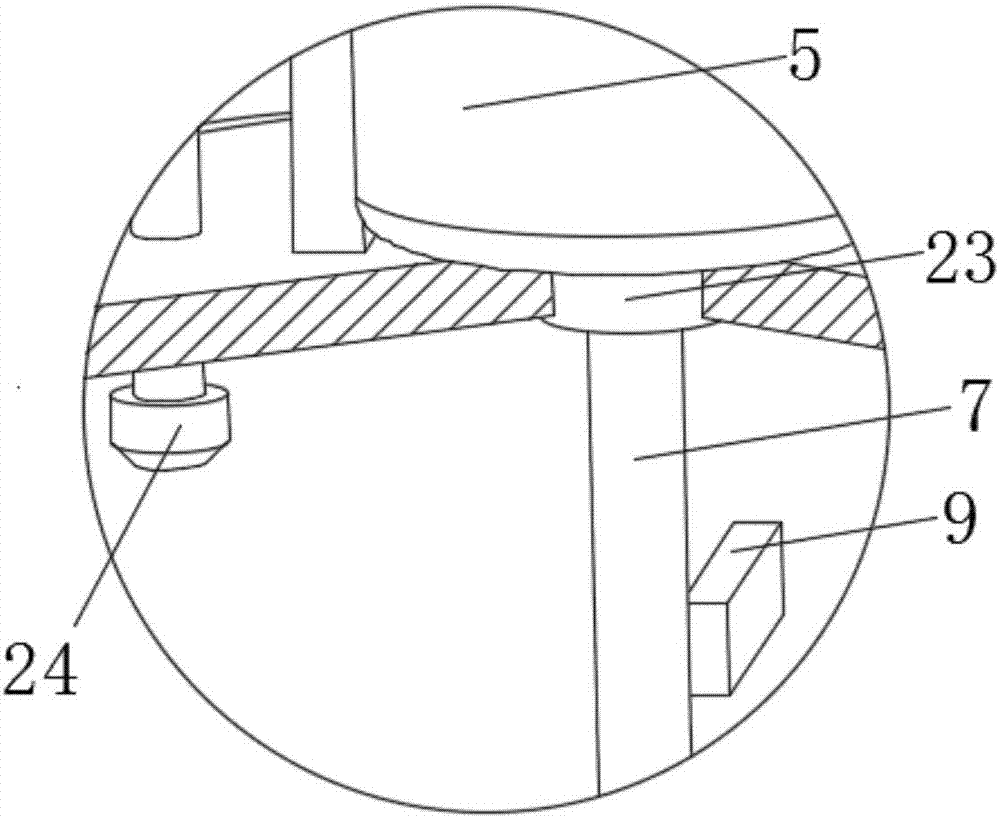

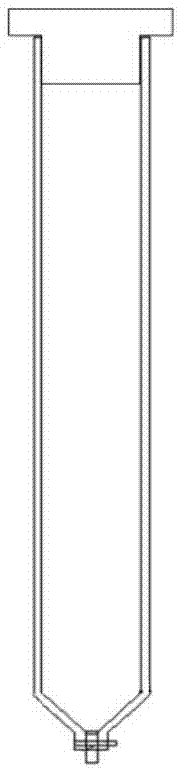

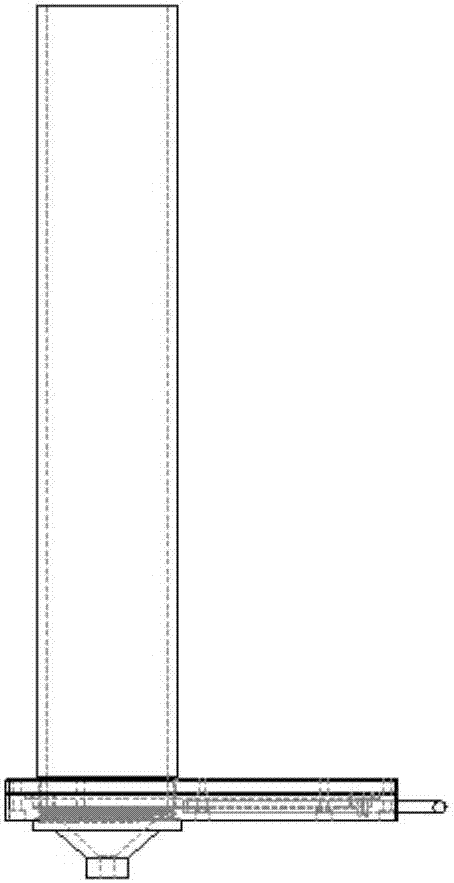

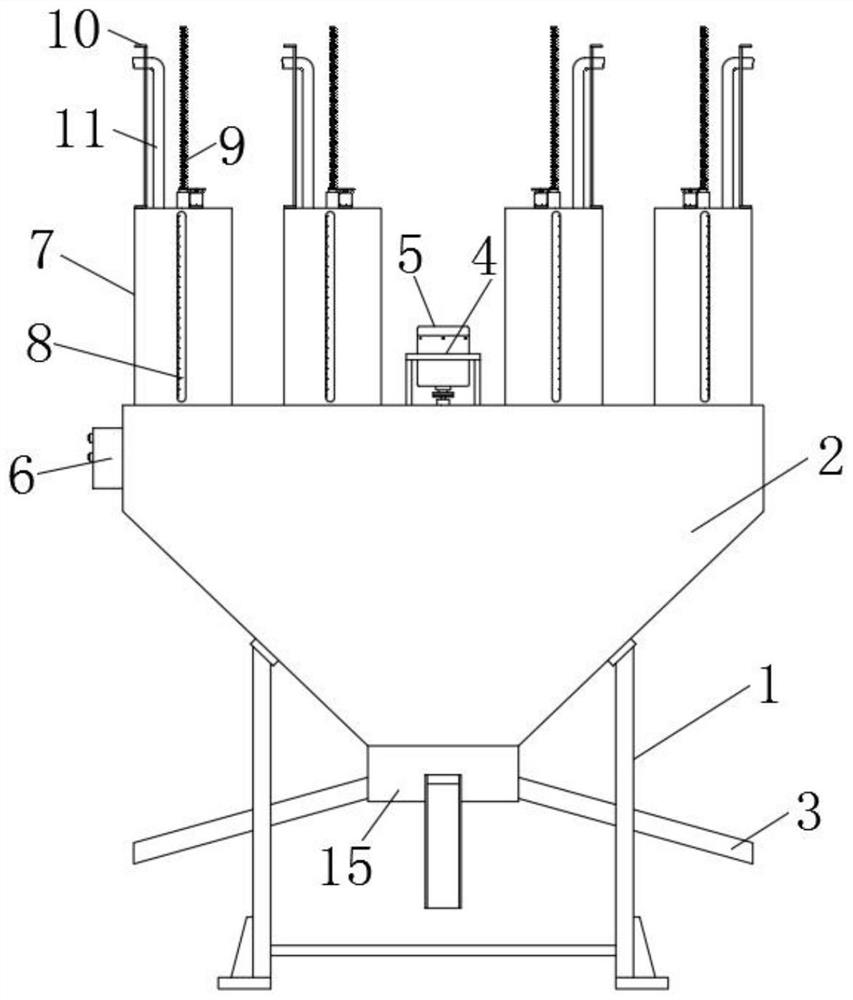

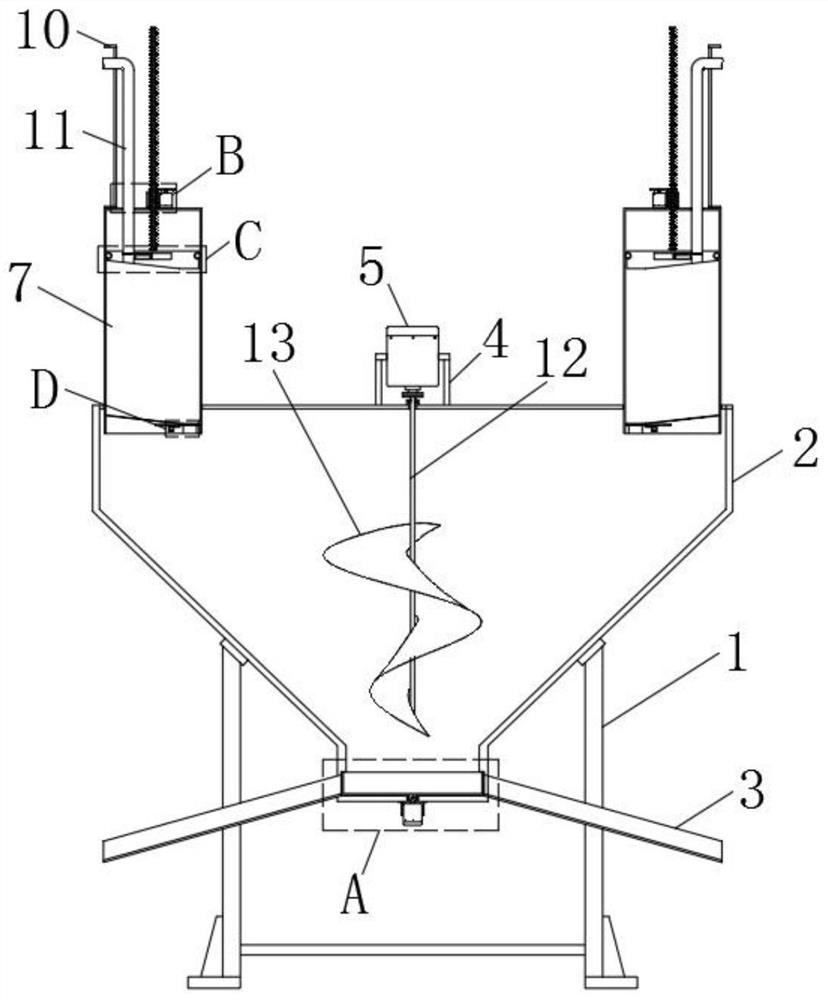

Settling separation device for phytoplankton

PendingCN107376436AAccurate volume controlConvenient volume workPreparing sample for investigationSettling tanks feed/dischargeAgricultural engineeringSedimentation

The invention discloses a settling separation device for phytoplankton. The settling separation device comprises an acrylic sleeve, an upper cover plate and a lower cover plate fixed with each other, wherein an upper cover plate hole is formed on the upper cover plate; the upper cover plate hole is connected with a bottom end of the acrylic sleeve; a separating plate slide slot is formed on the top surface of the lower cover plate; a lower cover plate hole is formed on the part corresponding to the position of the upper cover plate hole at the bottom of the separating plate slide slot; the lower cover plate hole is connected with the top of sedimentation glass; a water draining valve is arranged at the bottom of the sedimentation glass; a separating plate is arranged in the separating plate slide slot; the separating plate is connected with one end of a pull rod; and the other end of the pull rod is penetrated through a pull rod sealing ring embedded between the upper cover plate and the lower cover plate and a pull rod penetrating hole formed on the lower cover plate in turn and then is connected with a handle. According to the invention, the separating time after the settling of the phytoplankton sample is reduced by 80% or above, the settled phytoplankton is prevented from being disturbed and entering into supernate, the constant volume operation is convenient and the settling separation device is difficult to be damaged.

Owner:长江流域水环境监测中心

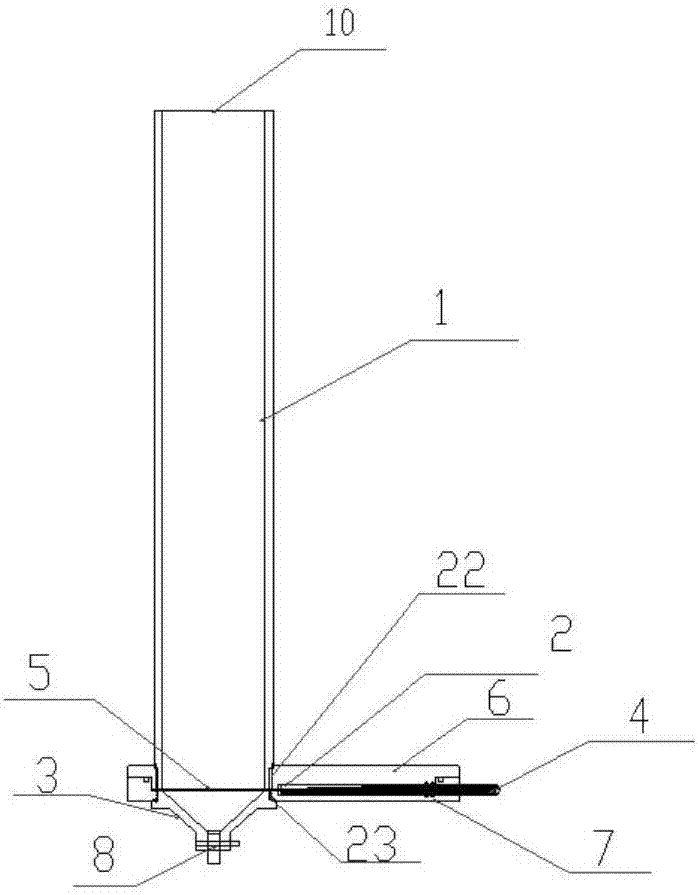

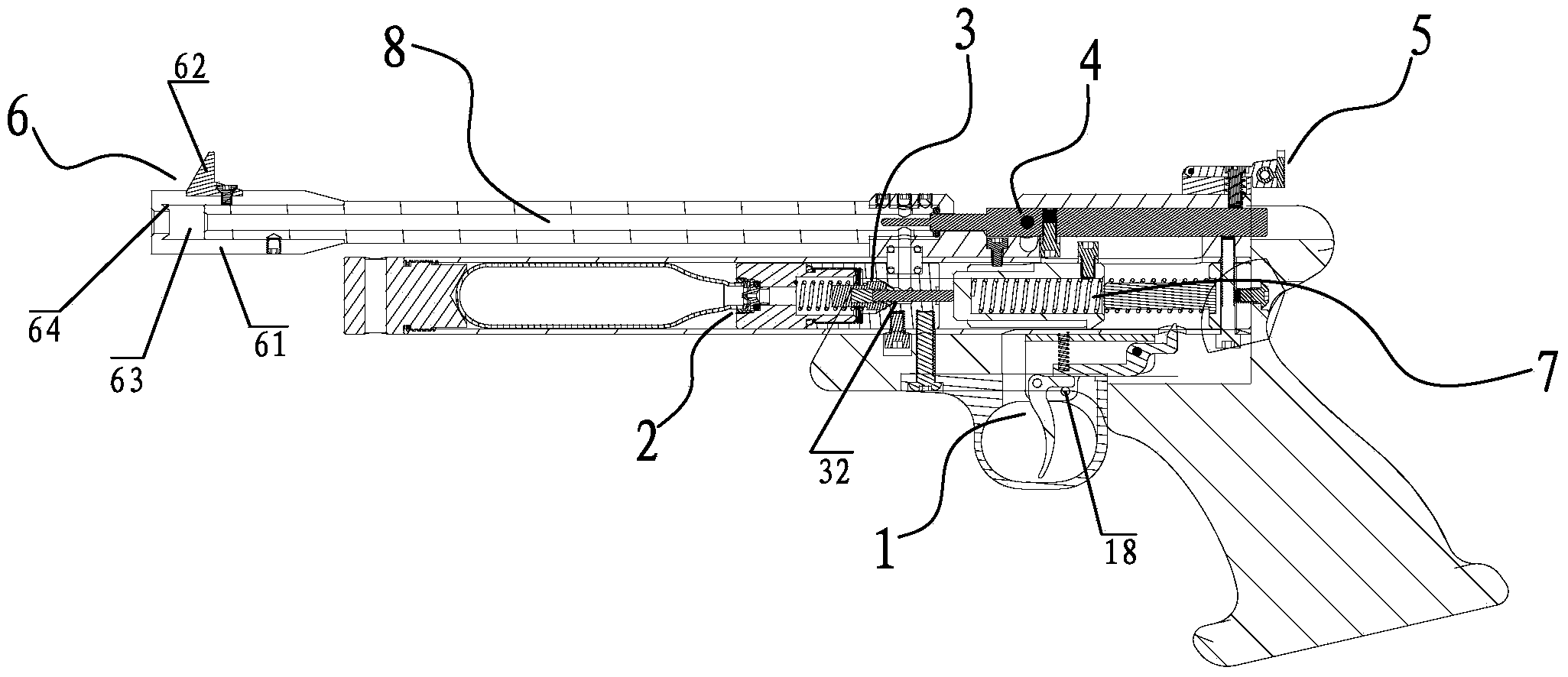

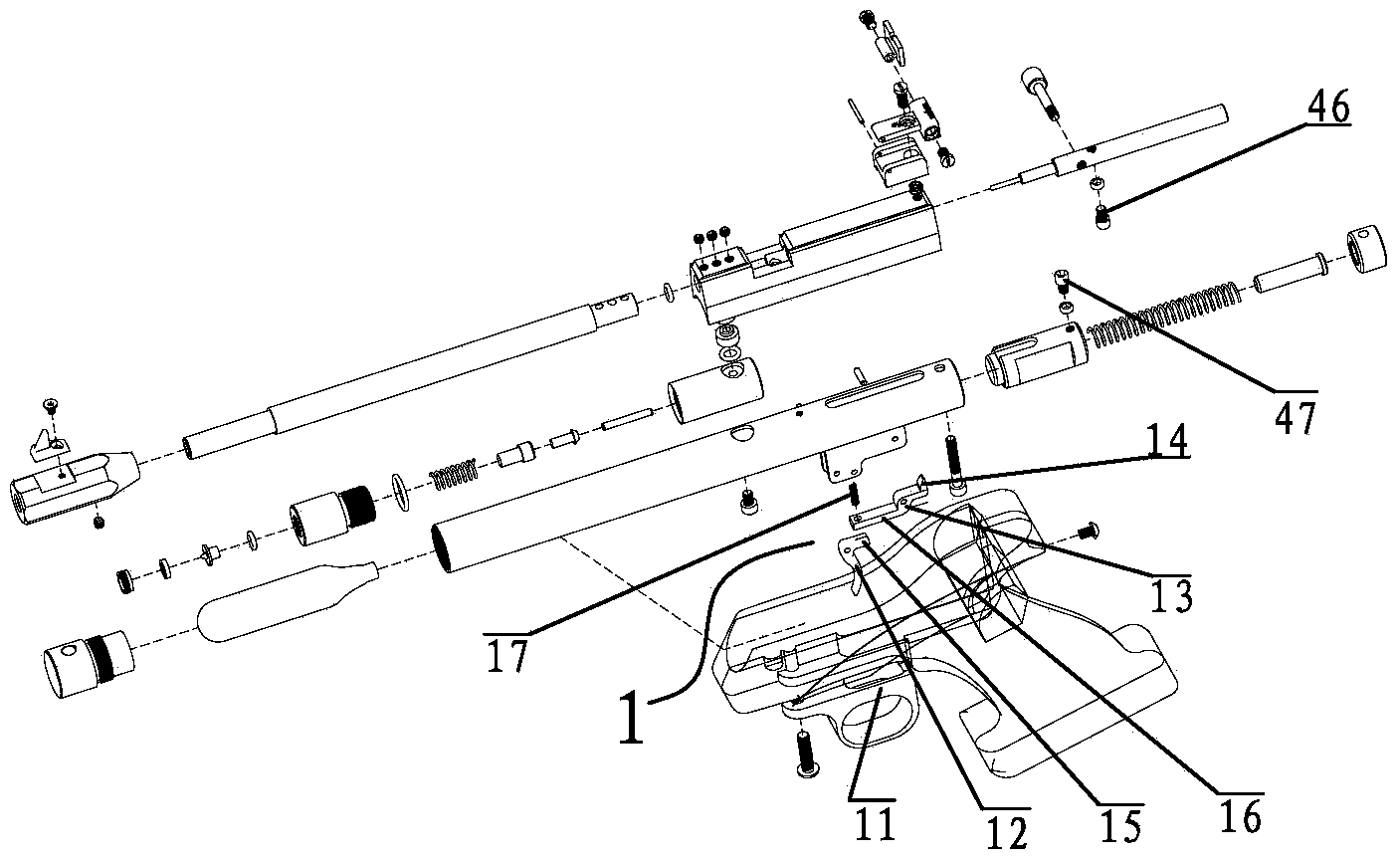

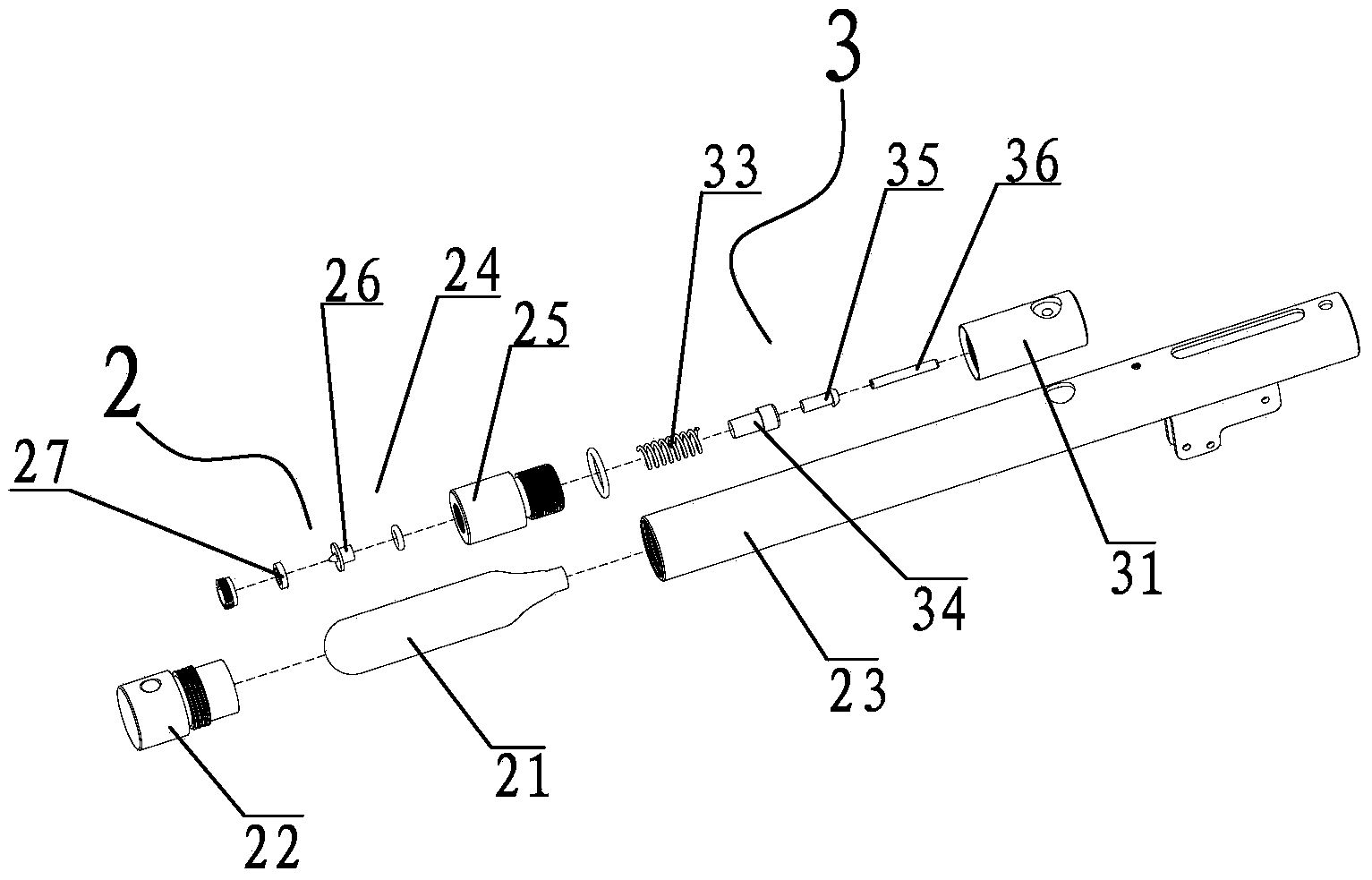

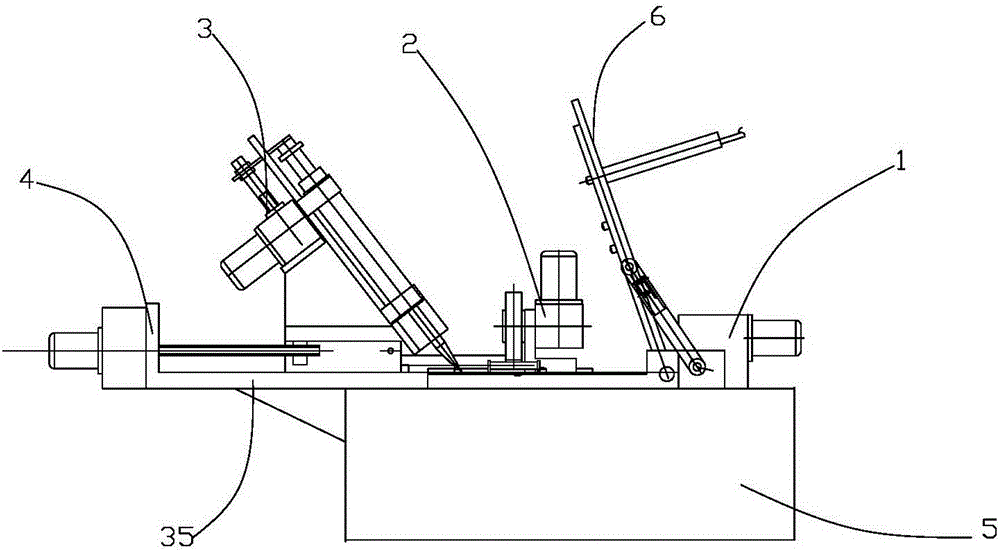

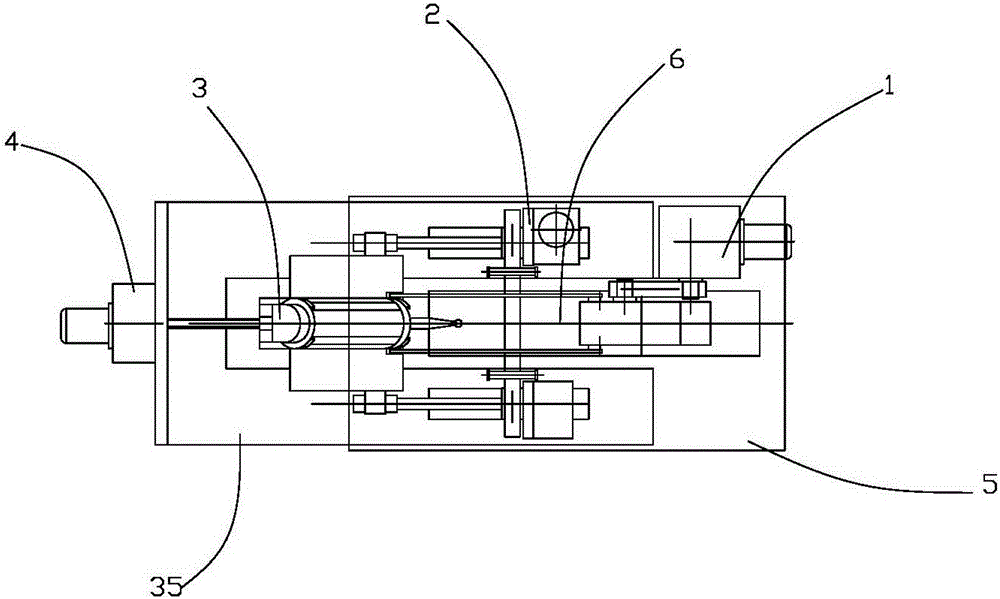

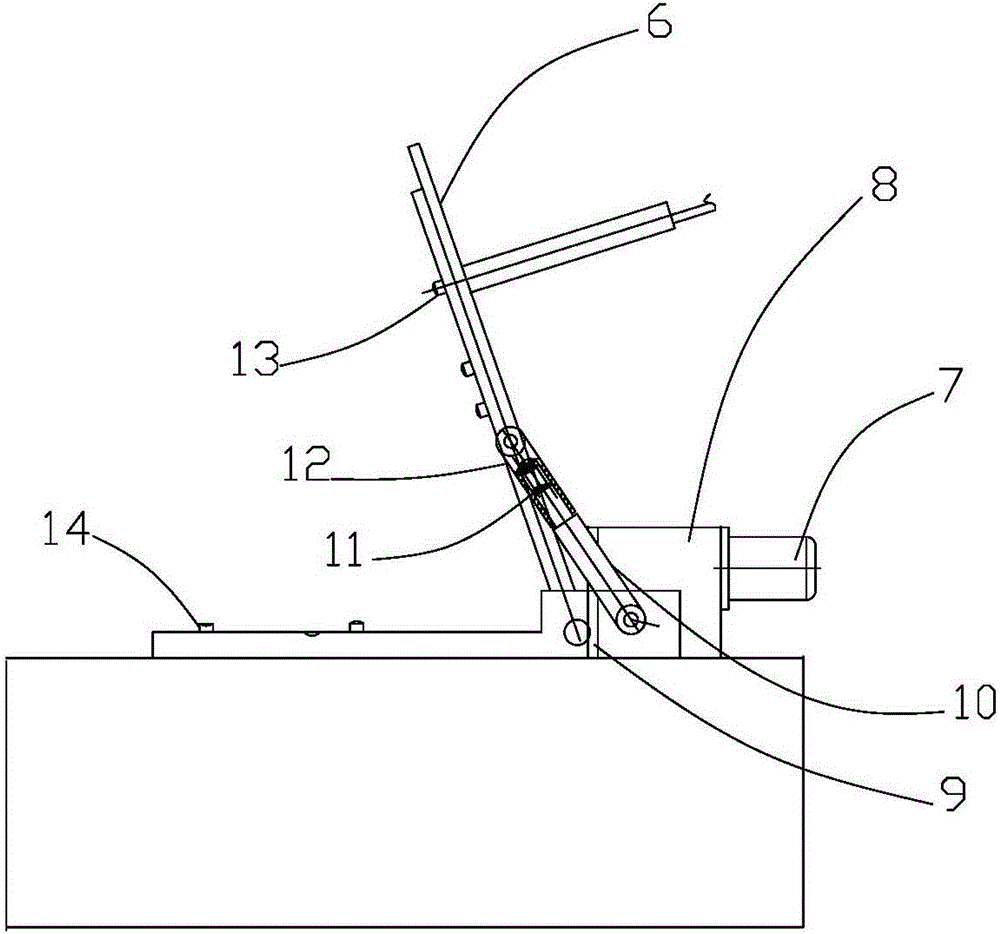

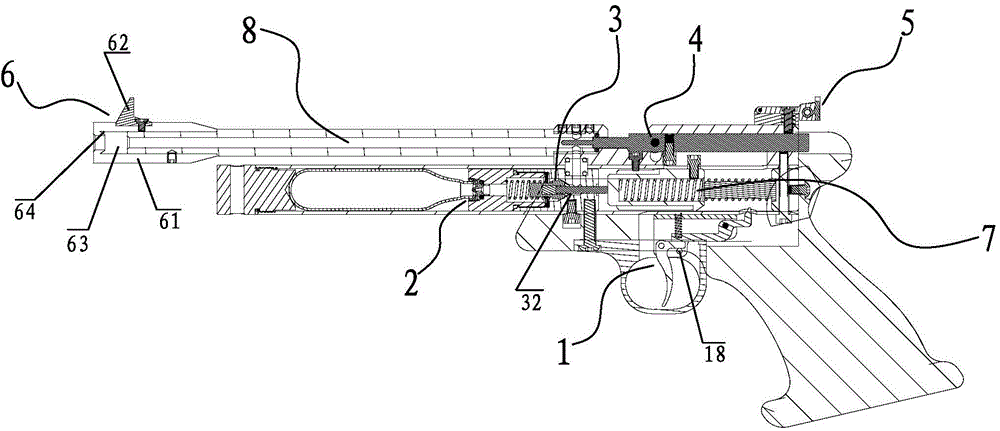

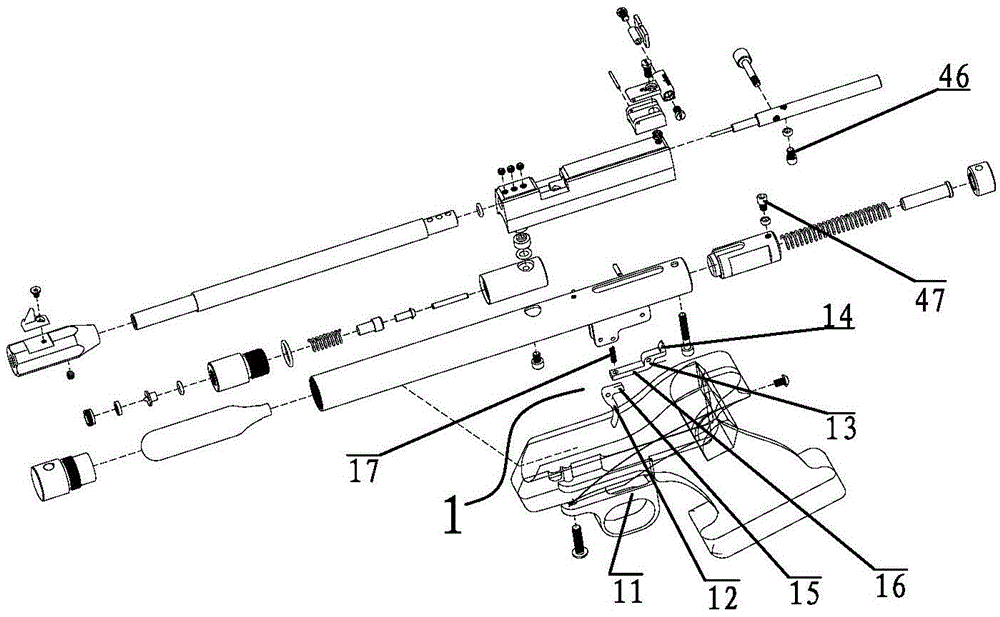

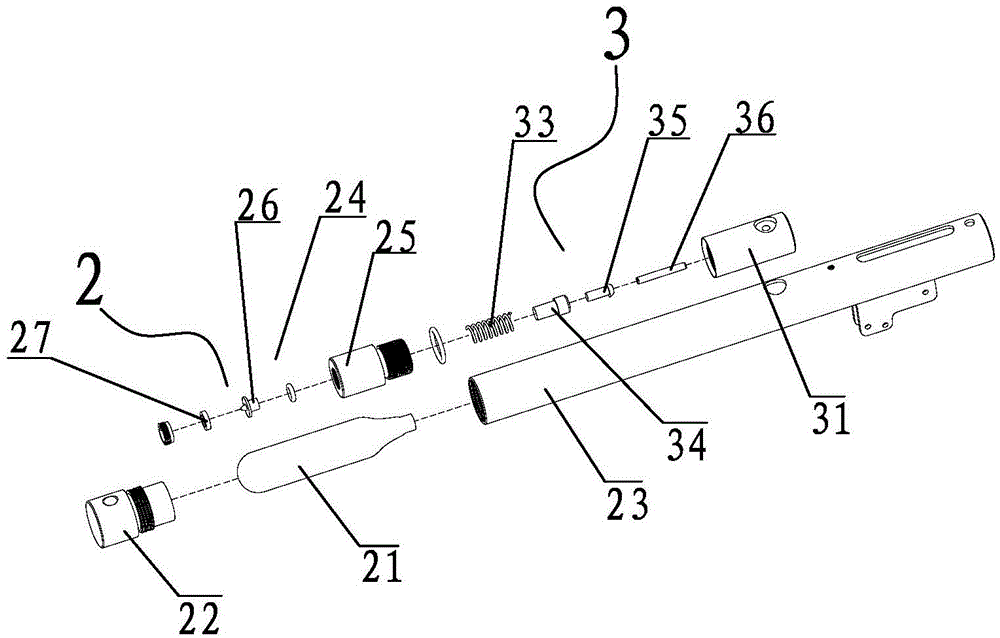

Air cylinder type air pistol

ActiveCN104034206AEffort-saving pullSimple structureFiring/trigger mechanismsSighting devicesGas cylinderInlet valve

The invention belongs to the field of air guns and particularly relates to an air cylinder type air pistol. The air cylinder type air pistol comprises a trigger mechanism, an air inlet device, an air outlet device, a loaded linkage mechanism, a sight device and a front sight device, wherein the air inlet device comprises an air cylinder, wherein the air cylinder is mounted in an air pipe through a locking sleeve, and the air outlet end of the air cylinder is connected with an air inlet structure; the air inlet structure comprises an air inlet valve, and a pricking pin is arranged in the air inlet valve; the air outlet device comprises a valve body component, one end of the valve body component is connected with the pricking pin, and the other end of the valve body component is abutted against an air outlet. The air cylinder type air pistol has the benefits that the operation is convenient, the structure is simple and practical, and a method for manually pressing air into an air chamber in the air gun during a shooting is eliminated.

Owner:SHAOXING LINGFENG AIR GUN MFG

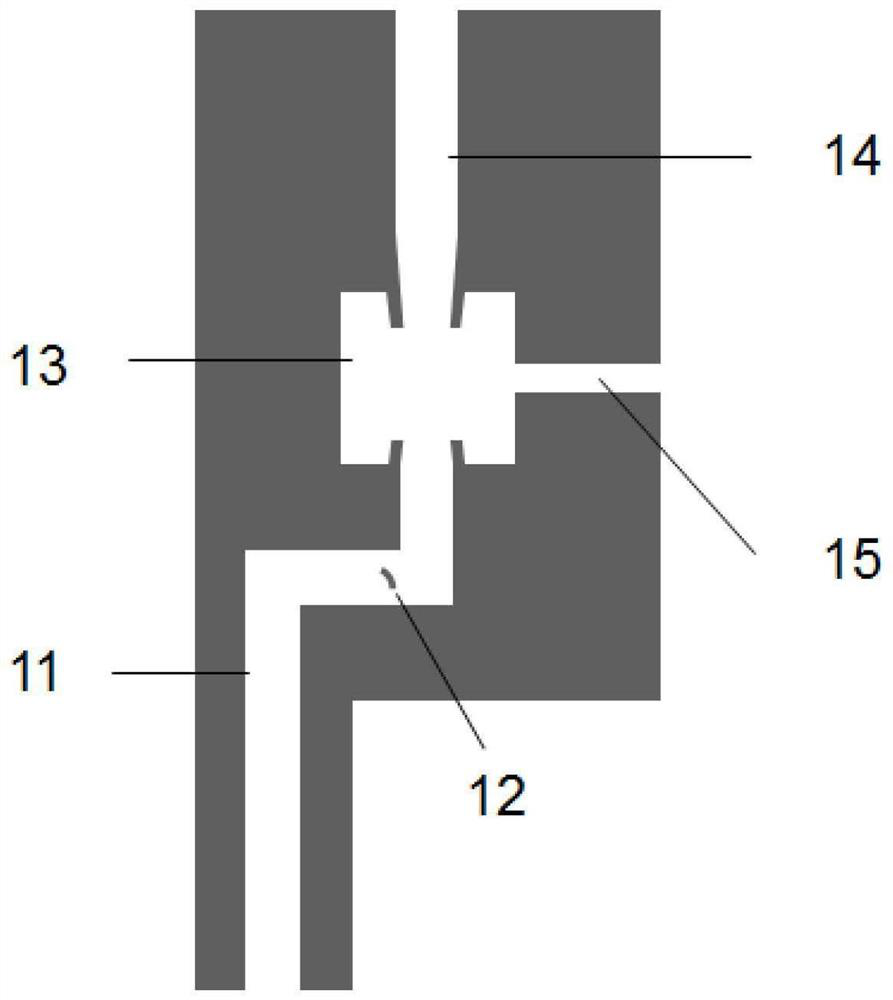

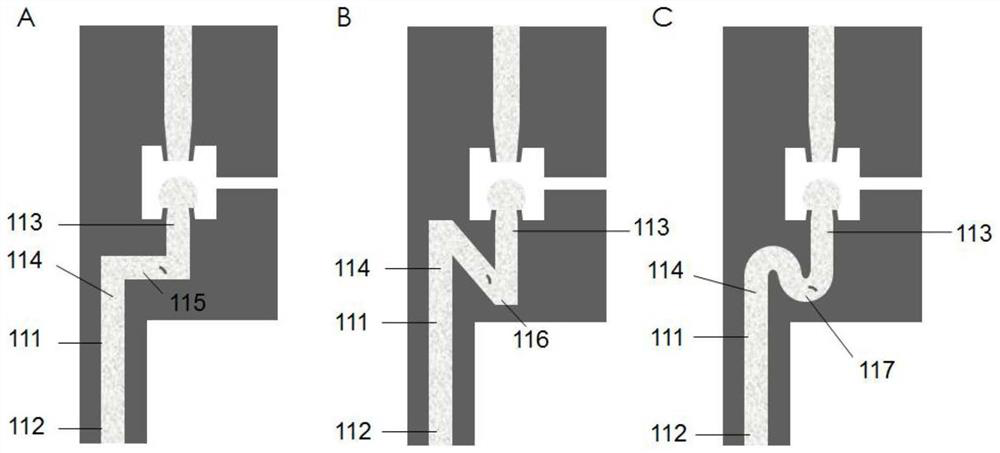

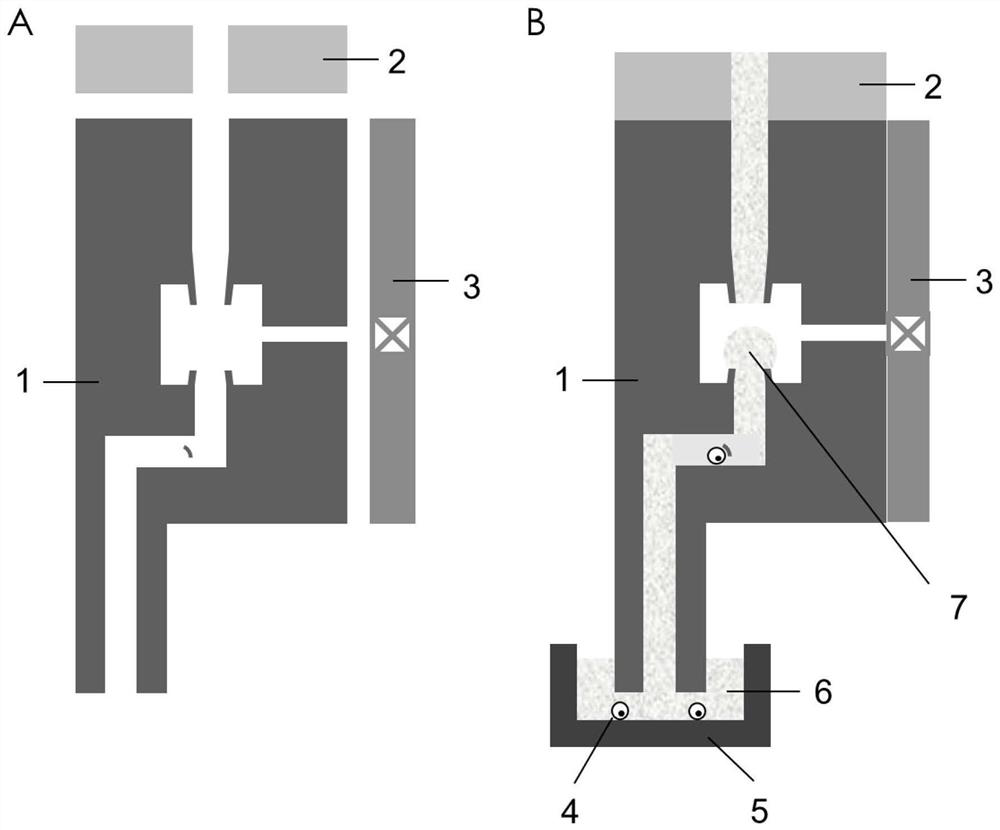

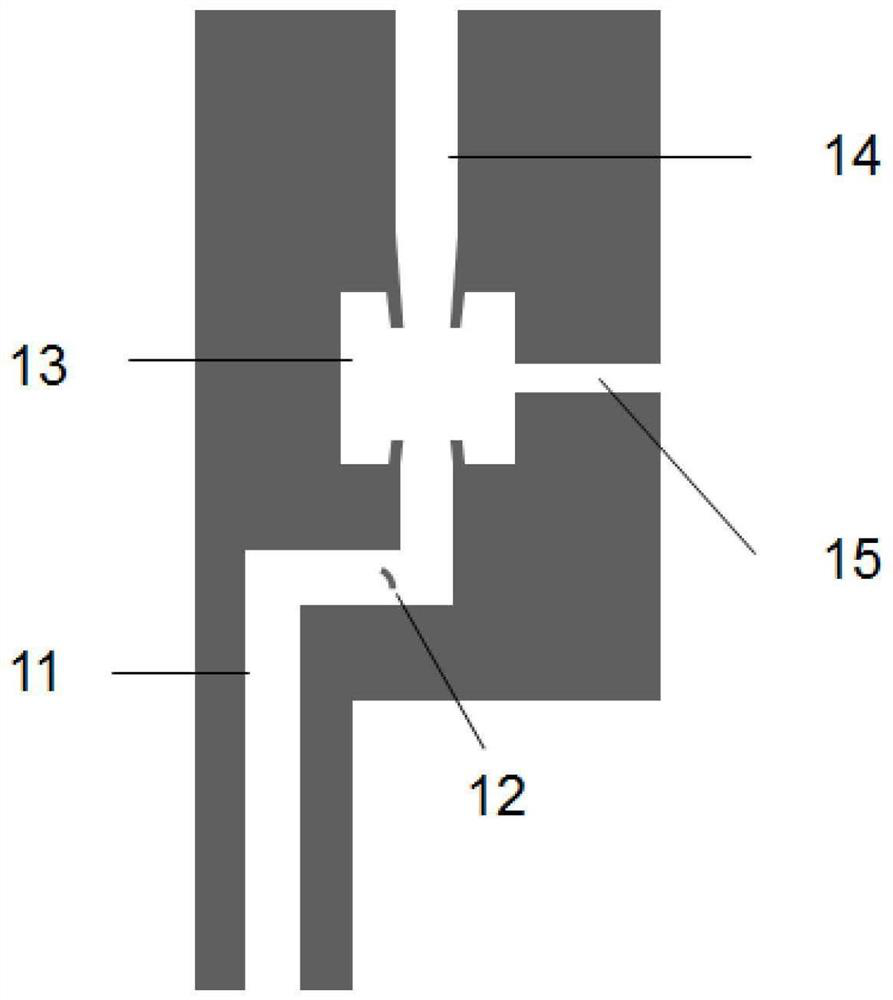

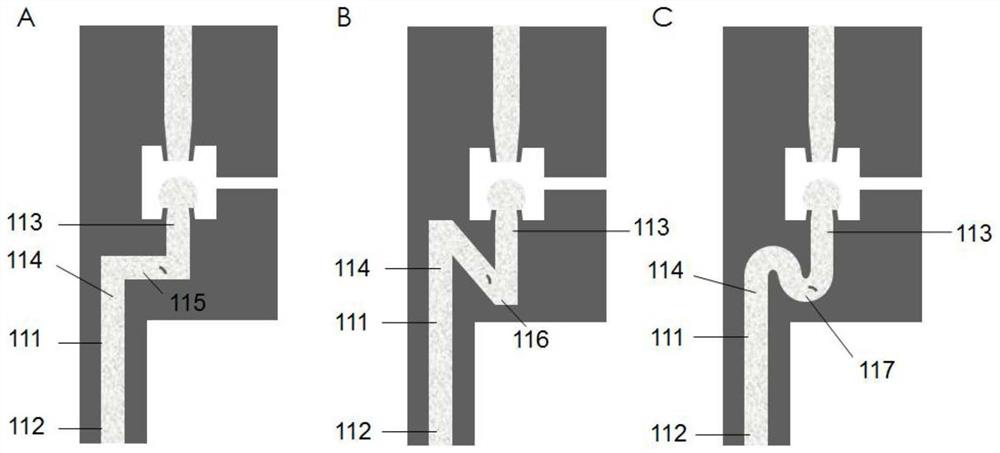

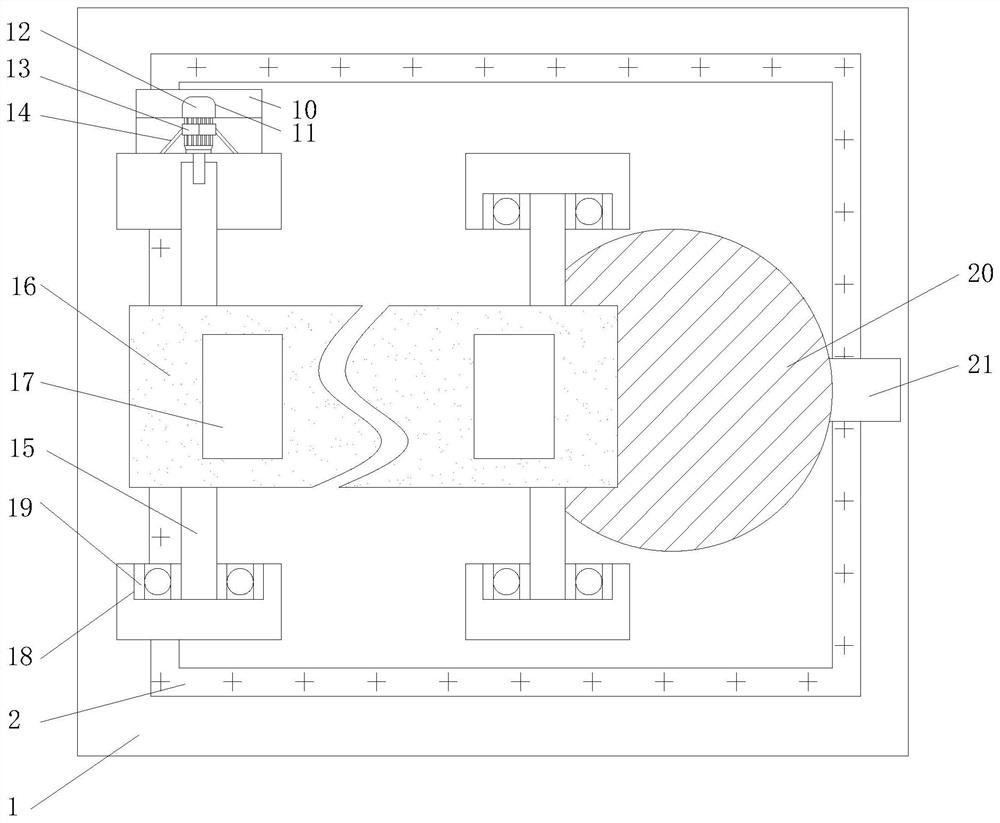

Micro-fluidic chip, and device and method for accurate and quantitative micro-fluidic operation of biological sample

ActiveCN112430531AControl resolutionHigh activityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiology

The invention relates to a microfluidic chip, and a device and method for accurate and quantitative micro-fluidic operation of a biological sample. The brand-new device and method capable of achievingdigital operation are provided for biological sample micro-flow operation, accurate quantification of liquid suction and removal is achieved for the first time through a digital droplet flow meter integrated in a micro-fluidic chip, and the device is used in cooperation with an external pressure applying mechanism capable of being repeatedly loaded and a valve. The concentration gradient of a liquid around the biological sample can be continuously adjusted in a digital droplet generation mode, so that continuous digital liquid dilution is realized, meanwhile, the amount of the liquid in contact with the biological sample during freezing and thawing can be quantitatively controlled, and the activity of cells and the sample in the freezing and thawing liquid change process of the biologicalsample is greatly improved.

Owner:苏州摩畅科技有限公司

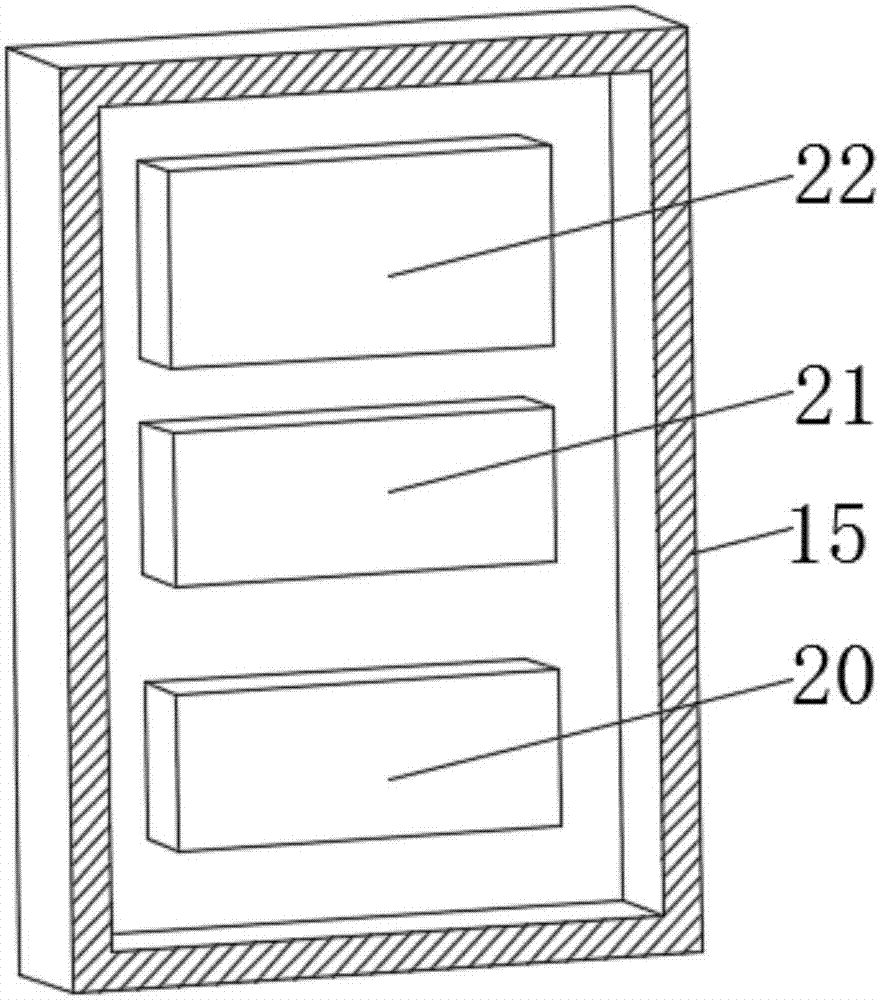

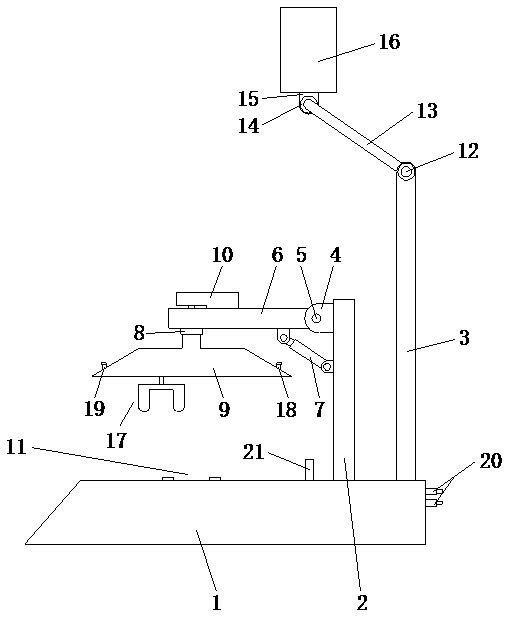

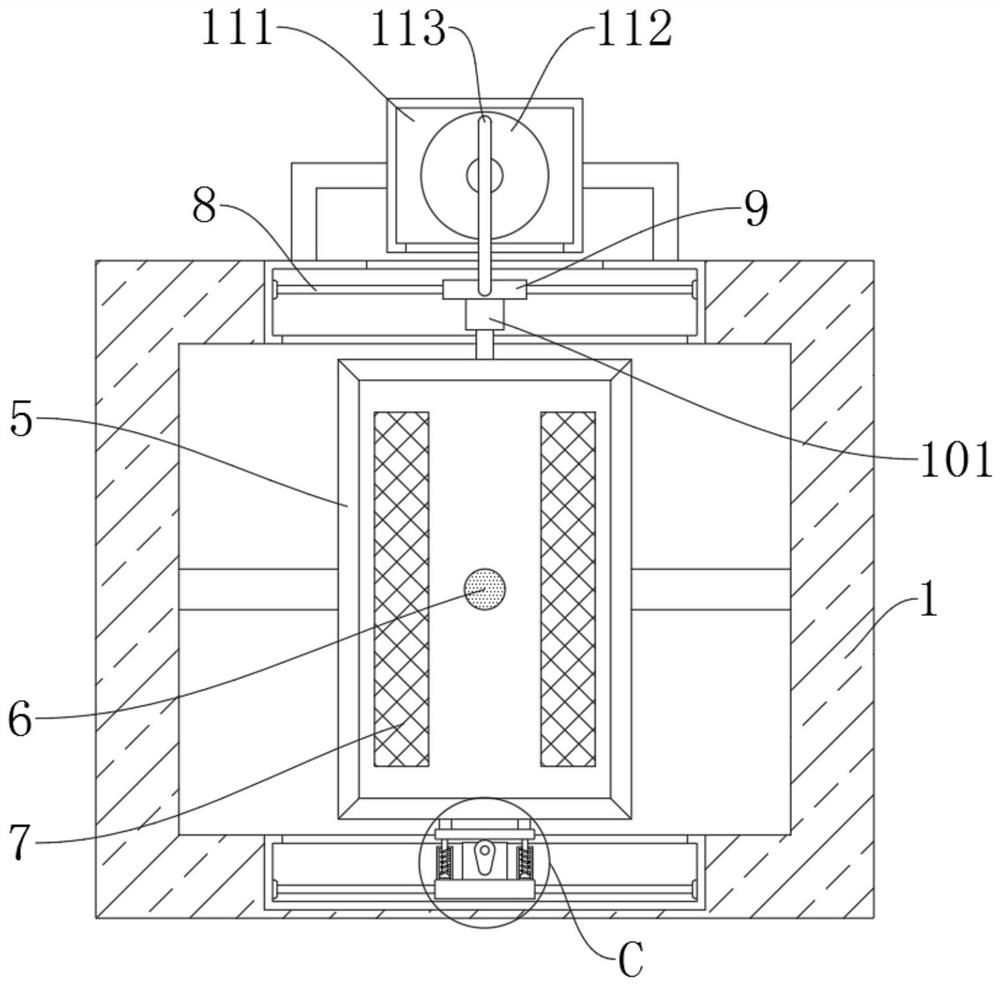

Intelligent cooking machine

InactiveCN110250906AAccurate volume controlSimple structureCooking-vessel lids/coversWarming devicesTemperature controlBrushless motors

The invention discloses an intelligent cooking machine. The intelligent cooking machine comprises a furnace body, a heating module is arranged in the furnace body, and the heating module is matched with the table surface of the furnace body. A temperature measurement mechanism is further arranged on the furnace body, a supporting column and a pair of vertical columns are longitudinally arranged on the rear side of the table surface of the furnace body, a rotary shaft seat is arranged on the front side of the upper end of the supporting column, a rotary shaft is arranged in the rotary shaft seat, a cantilever is arranged on the rotary shaft, a drive cylinder is arranged between the cantilever and the supporting column, and two ends of the drive cylinder are separately hinged to the cantilever and the supporting column. A connector is fixedly arranged at the lower end of the cantilever, a pot cover is detachably connected to the lower end of the connector, a brushless motor is arranged at the upper end of the cantilever, first damping rotary shafts are separately arranged on the inner sides of the corresponding upper ends of the vertical columns, connection rods are arranged on the first damping rotary shafts, second damping rotary shafts are arranged between the connection rods, a cross rod is arranged between the second damping rotary shafts, and a human-computer interaction interface is arranged on the cross rod. The intelligent cooking machine is higher in automation degree, is more intelligent and realizes high-precision temperature control, and meanwhile, the intelligent cooking machine is more accurate in control quantity of edible oil and water.

Owner:南通市天行信息科技发展有限公司

Microfluidic chip, device and method for precise quantitative biological sample microfluidic manipulation

ActiveCN112430531BControl resolutionHigh activityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiology

A microfluidic chip, a device and method for microfluidic manipulation of precise quantitative biological samples. The present invention proposes a brand-new digitally operable device and method for the microfluidic operation of biological samples. The digital droplet flowmeter integrated in the microfluidic chip realizes the precise quantification of liquid inhalation and removal for the first time, and can be repeatedly loaded with the external With the use of advanced pressure mechanism and valve, the liquid concentration gradient around the biological sample can be continuously adjusted by means of digital droplet generation, thereby realizing continuous digital liquid dilution, and quantitatively controlling the liquid in contact with the biological sample during freezing and thawing. The amount can greatly improve the activity of cells and samples during the freezing and thawing of biological samples.

Owner:苏州摩畅科技有限公司

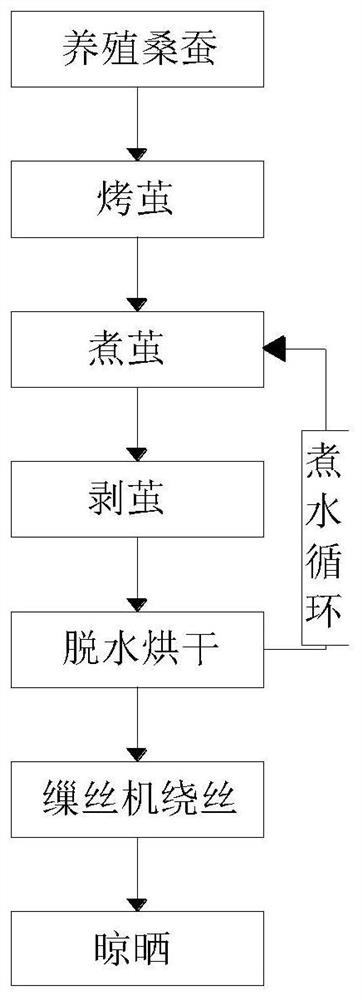

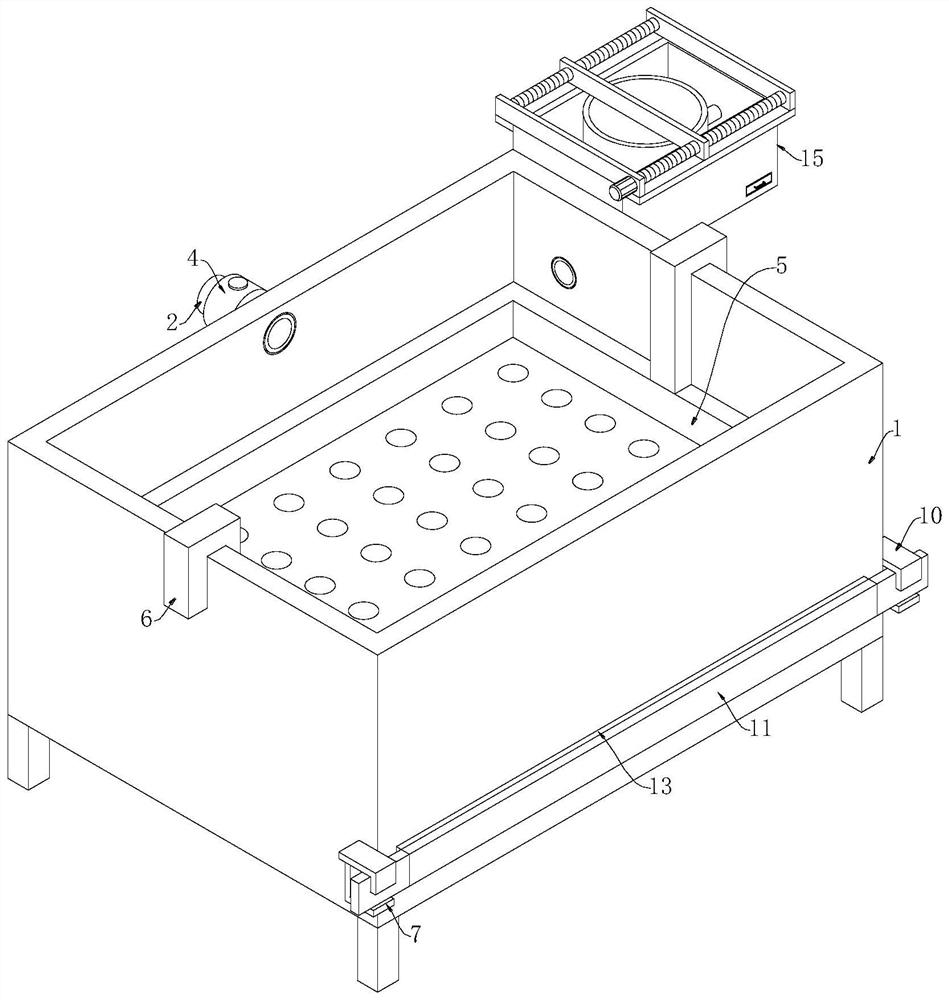

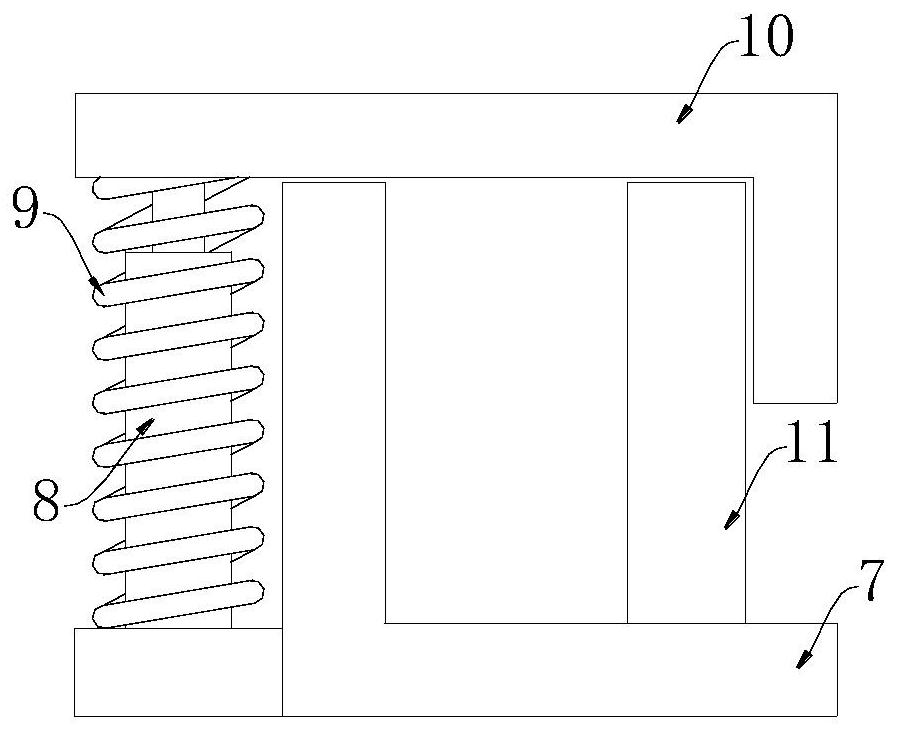

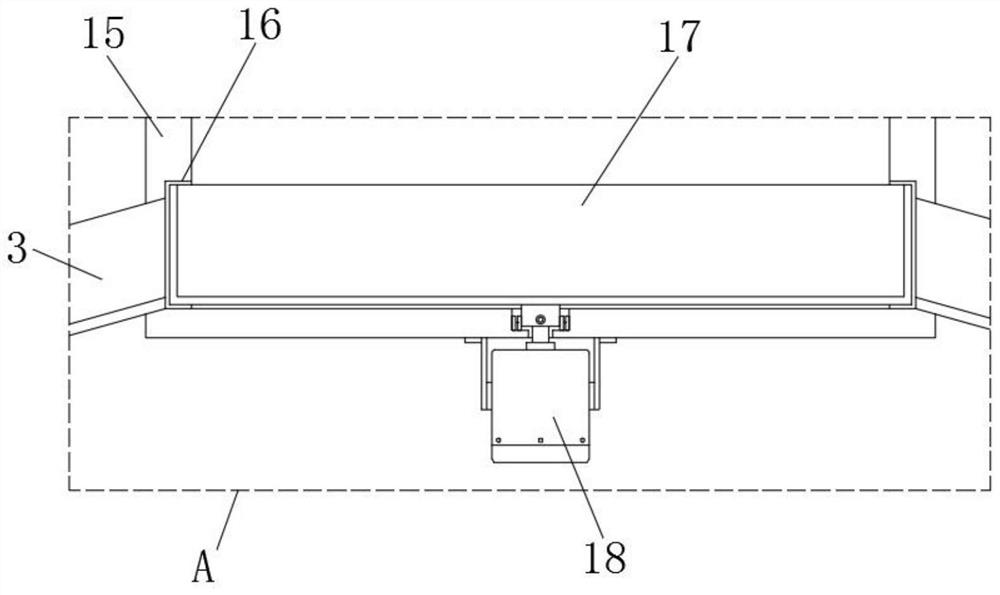

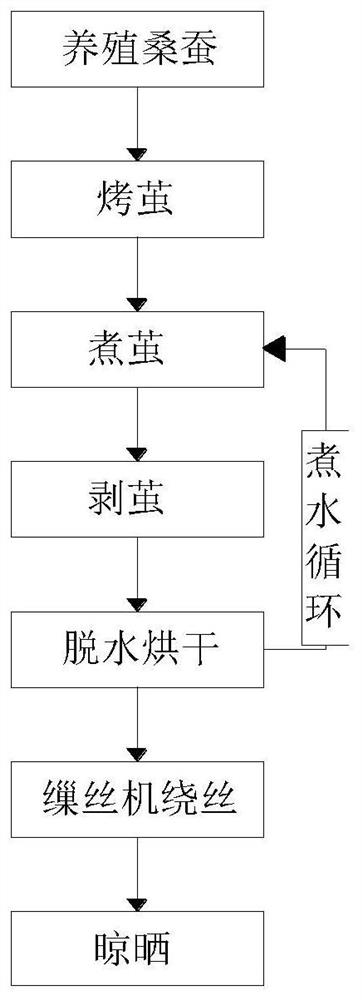

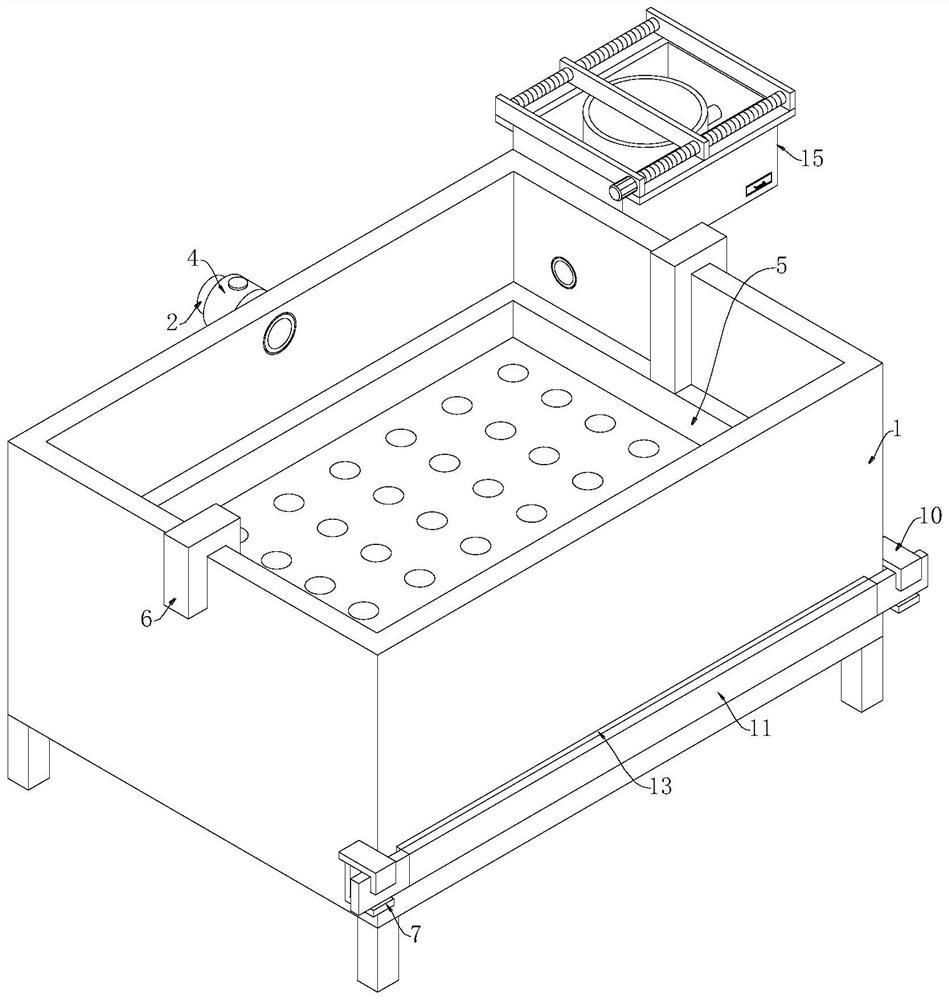

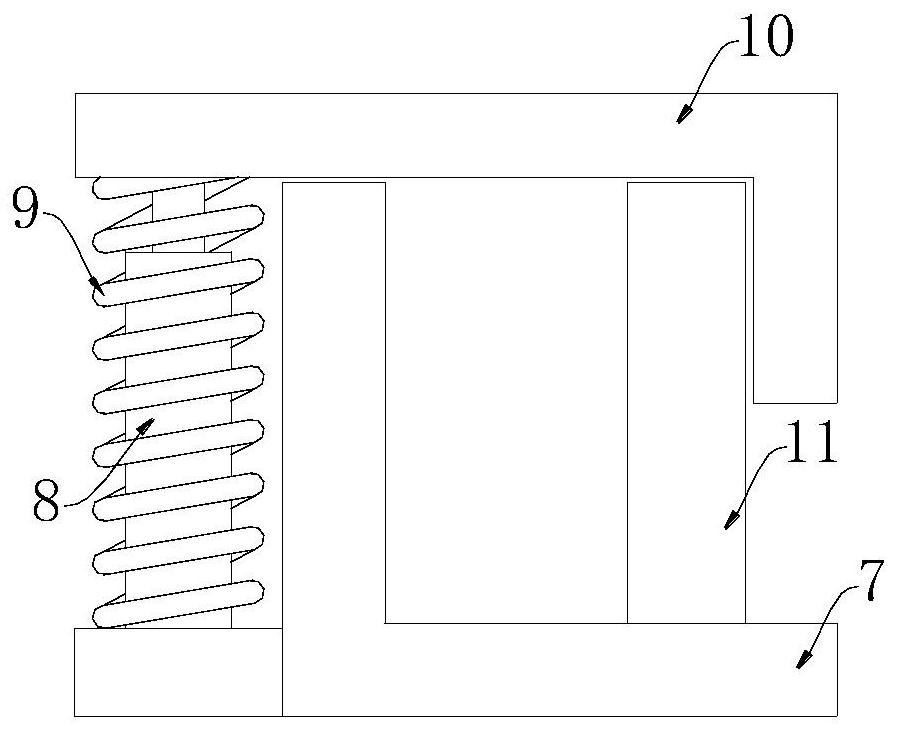

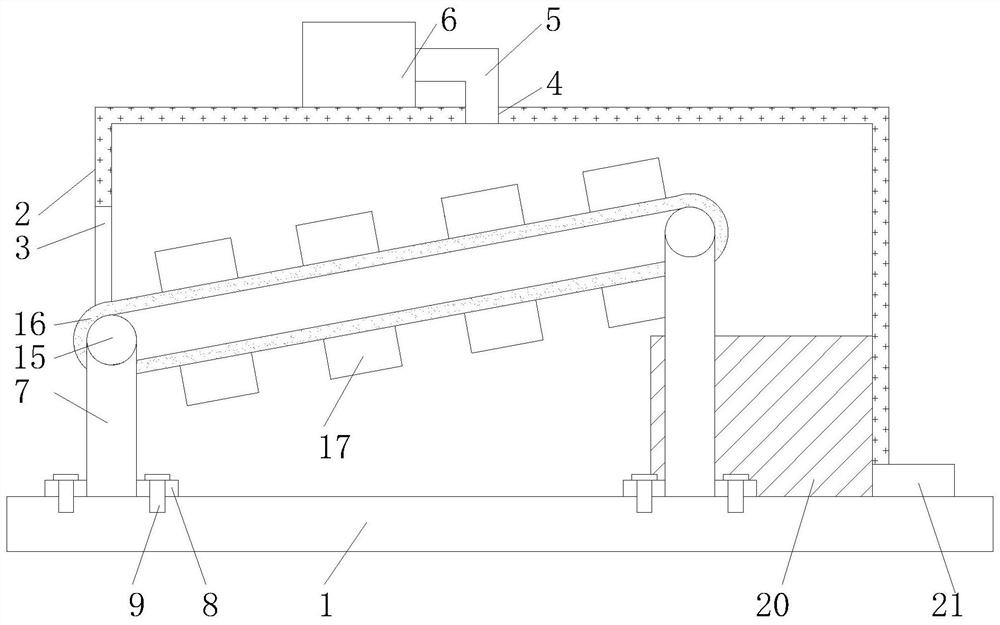

Environmentally-friendly silk quilt manufacturing technology and device

ActiveCN111676522AEasy to produceIncrease productivityBlanketDrying solid materials without heatEngineeringProcess engineering

The invention discloses an environmentally-friendly silk quilt manufacturing technology. The environmentally-friendly silk quilt manufacturing technology comprises the following steps that silkworms are bred; the silkworms are put on a baking trolley and pushed into an oven, the silkworms are baked, the baking temperature is set to be 85 DEG C, and the baking time is set to be 22min; and the bakedsilkworms are put into a cocoon cooking mechanism, and sodium carbonate is added to the cocoon cooking mechanism through a throwing mechanism. According to the environmentally-friendly silk quilt manufacturing technology, due to the cooperative utilization of a second motor, a rotating shaft and connecting rods, a worker can control the rotation of an output shaft of the second motor, the outputshaft of the second motor can drive the rotating shaft and the connecting rods to rotate, silk cotton bags which are fixed to clamping mechanisms can rotate along with the rotating shaft and the connecting rods, and the moisture on the silk cotton bags is removed; after the moisture is removed, the silk cotton bags are subjected to drying treatment through the hot air generated by air heaters, thesilk cotton bags can be subjected to water removal and drying operation in sequence after the silk cotton bags are put into a drying box, and therefore the production process is simplified, the silkcotton bags do not need to be repeatedly taken and placed, and the production efficiency is improved.

Owner:江西金铭丝绸有限公司

Safe and efficient infusion and oxygen delivery device for emergency department

The invention provides a safe and efficient infusion and oxygen delivery device for the emergency department, and relates to the technical field of medical instruments. The movable supporting device is fixedly connected with an oxygen inhalation mounting part; a floating positioning device is mounted on the oxygen inhalation mounting part; a liquid collecting device is fixedly connected between the two positioning pieces; four flow dividing devices are fixedly embedded in the liquid collecting device; four quantity control driving parts are mounted on the liquid collecting device; the four quantity control driving parts are aligned with the four flow dividing devices; the bottom of the liquid collecting device is fixedly connected with a linkage flow stopping part; the bottom of the linkage flow stopping part is fixedly connected with a liquid shortage safety device, infusion is safer, meanwhile, safe blocking can be achieved in an auxiliary mode, quantity control is more accurate, air pollution can be effectively avoided, and the problems that an existing infusion and oxygen delivery device cannot effectively achieve automatic liquid shortage blocking, medical accidents are likely to be caused, potential health hazards exist, and the safety is high are solved. And meanwhile, free regulation and control of multiple bags of medicines cannot be realized.

Owner:张绍新

Ventilation device

ActiveUS10041496B2Accurate flowAccurate volume controlEfficient regulation technologiesPump controlElectrical resistance and conductanceAir volume

Between the lower stage in respective phases of inverter circuit and the negative potential side, shunt resistors are inserted for respective phases. The potential differences across shunt resistors occurring by current flowing through shunt resistors are amplified by amplifier unit. From the output of amplifier unit, current detecting unit detects current of each phase flowing through motor formed by a sensorless brushless DC motor. Rotation detecting unit calculates the rotation speed and position of motor based on the current detected by current detecting unit. This structure makes it possible to directly detect solely the current flowing through the windings of motor. Therefore, it becomes possible to accurately detect the current of the motor windings, and the ventilation device can maintain the ventilation air volume from a small air volume to a large air volume always at a constant value.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

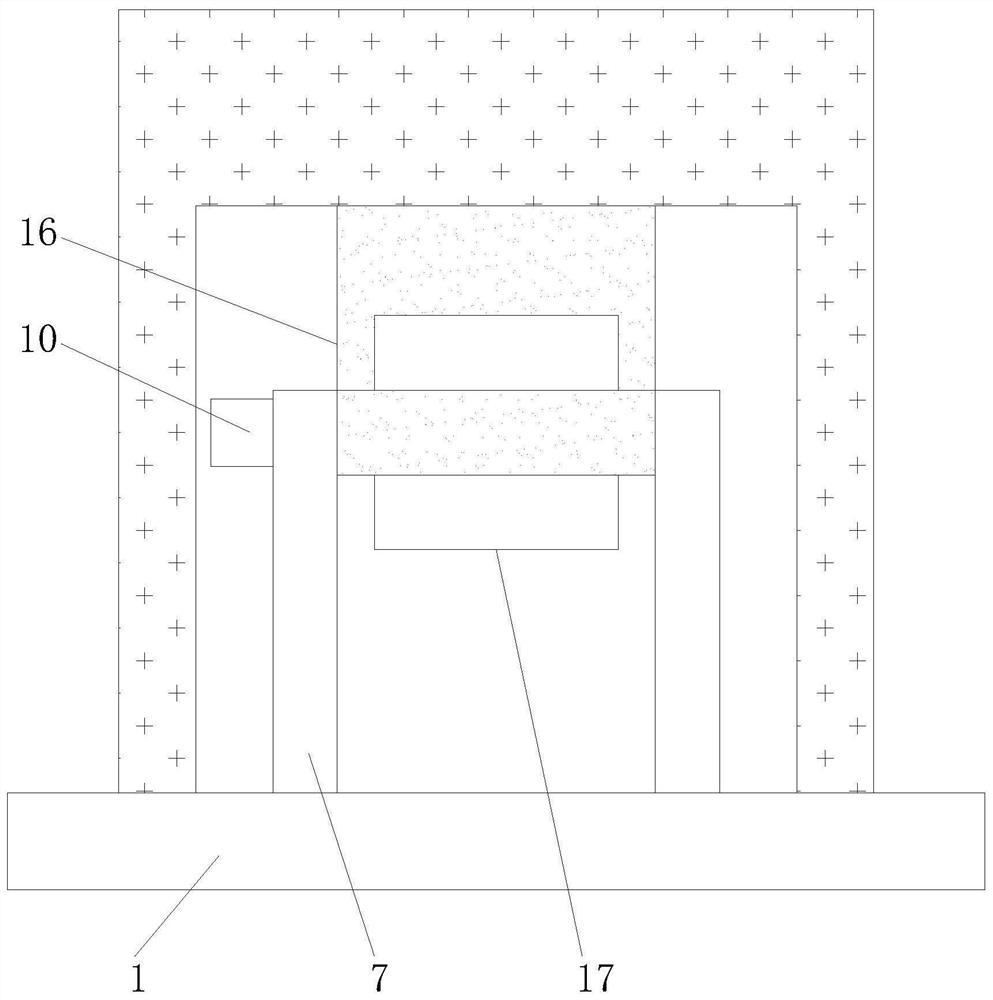

Recycling device for autoclaved aerated concrete block cutting waste

InactiveCN113477685AAccurate volume controlGuaranteed Particle SizeSolid waste disposalGrain treatmentsGear wheelElectric machinery

The invention discloses a recycling device for autoclaved aerated concrete block cutting waste. The recycling device comprises a mixing cabin, a feed inlet and a stirring mechanism, wherein the feed inlet is formed in one side of the mixing cabin, the stirring mechanism is arranged in the mixing cabin and composed of a driving motor and a stirring rod, and baffles are hinged in the top end of the mixing cabin; and an opening and closing assembly for adjusting the angles of the baffles is arranged between the mixing cabin and the baffles. According to the recycling device for the autoclaved aerated concrete block cutting waste, through cooperation of the baffles, first gears, first half gears, first springs, a collecting cabin and a weighing sensor, accurate quantity control over the waste is achieved, and the concentration of follow-up mixing is ensured; and meanwhile, through cooperation of a second half gear, a torsion spring, a second gear and a beating plate on the baffles, large waste materials can be conveyed into the collecting cabin after being treated, the particle size of waste materials is ensured, subsequent mixing is more convenient and stable, and it is ensured that waste material recycling work is stably carried out.

Owner:繁昌县鑫华建材科技有限公司

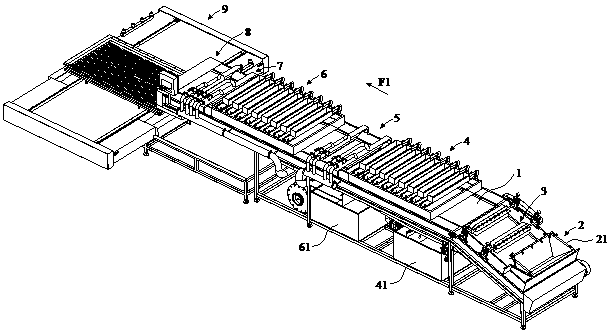

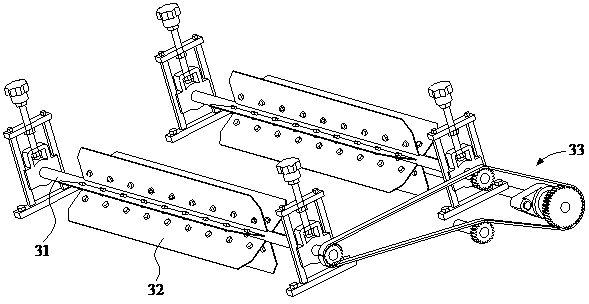

Chinese wolfberry fruit automatic cleaning production line and working method thereof

InactiveCN108354200ALoading speed blockImprove qualityFood treatmentLycium barbarum fruitCleaning station

The invention relates to a Chinese wolfberry fruit automatic cleaning production line and a working method thereof. The Chinese wolfberry fruit automatic cleaning production line comprises a first conveying device and cleaning stations, wherein the first conveying device is suitable for transporting Chinese wolfberry fruit granules to the cleaning stations for cleaning the Chinese wolfberry fruitgranules. The Chinese wolfberry fruit automatic cleaning production line disclosed by the invention is high in automation degree, high in production efficiency, low in labor cost, accurate in diskingcapacity control, and high in disking speed; and through two cleaning stations, the quality of Chinese wolfberry fruits is greatly improved.

Owner:常州市昇源干燥设备科技有限公司

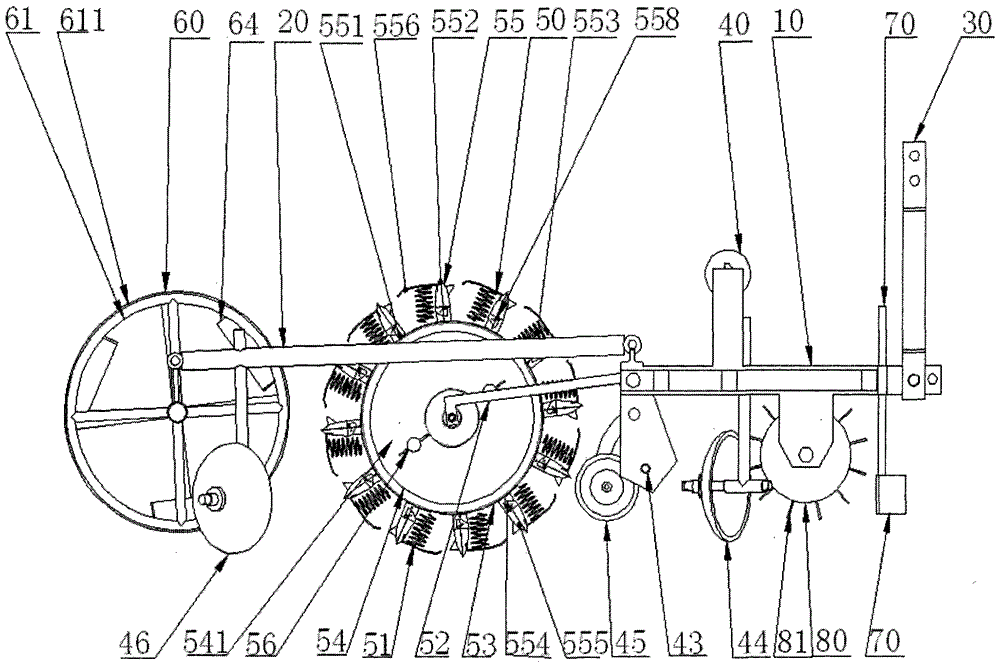

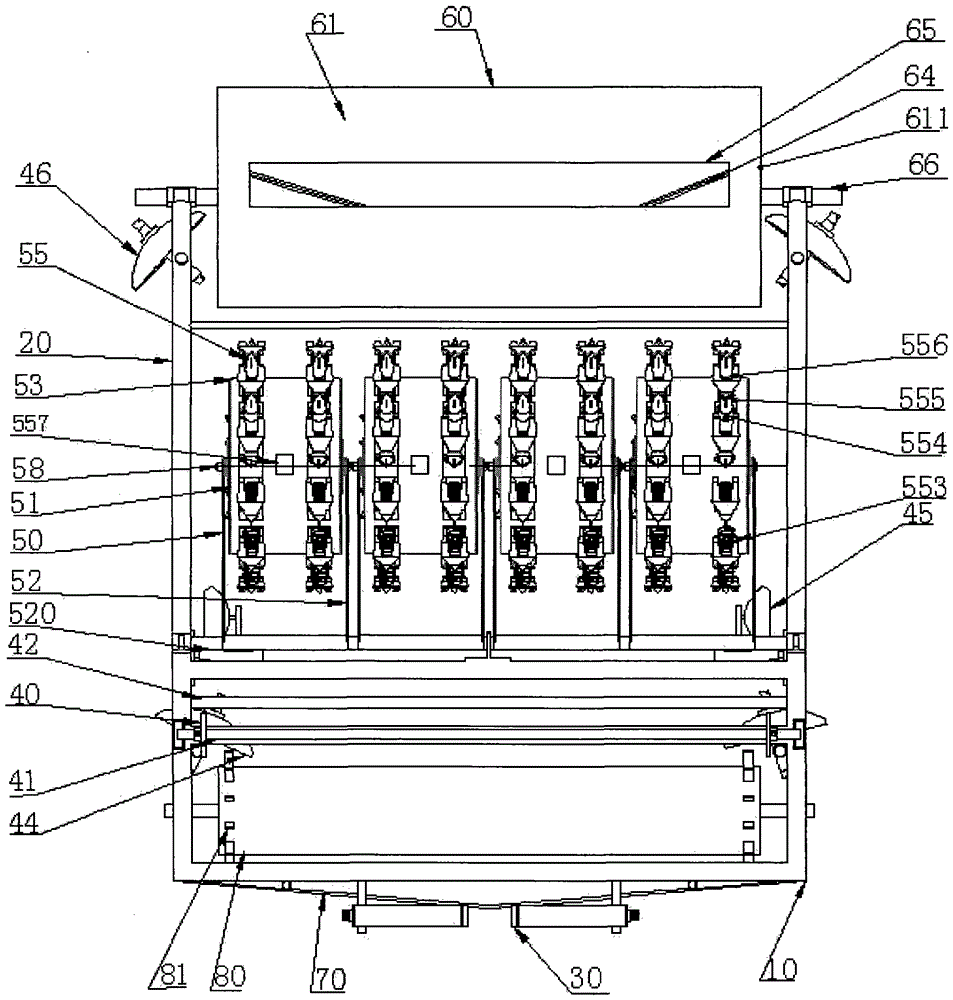

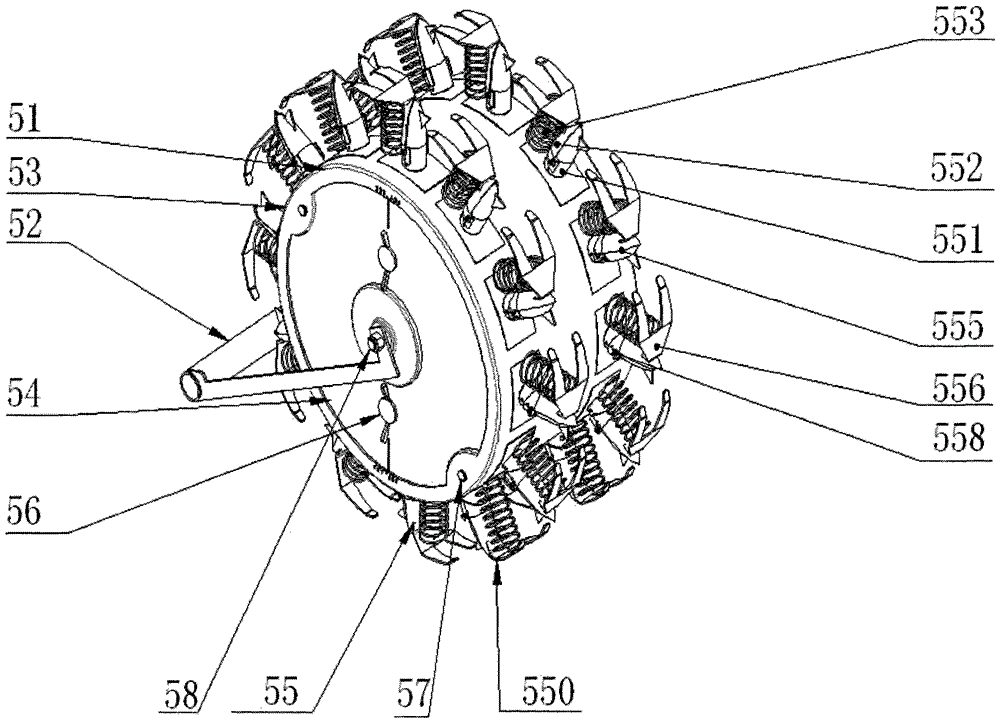

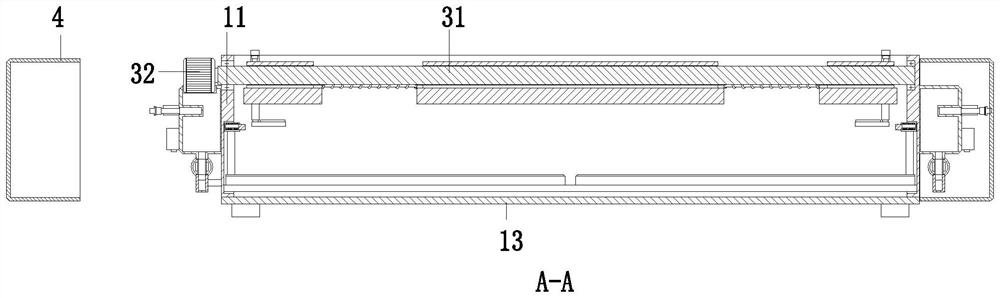

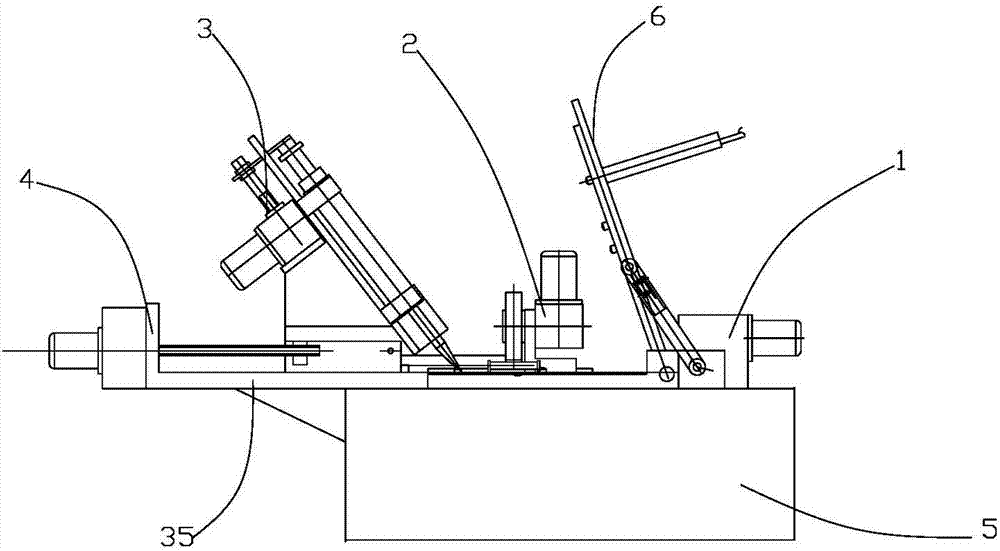

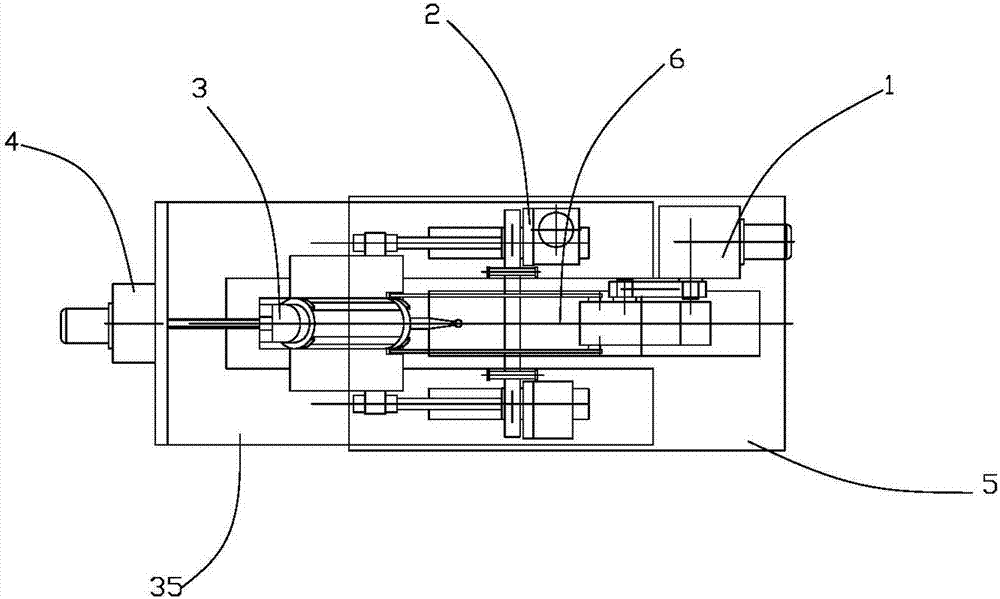

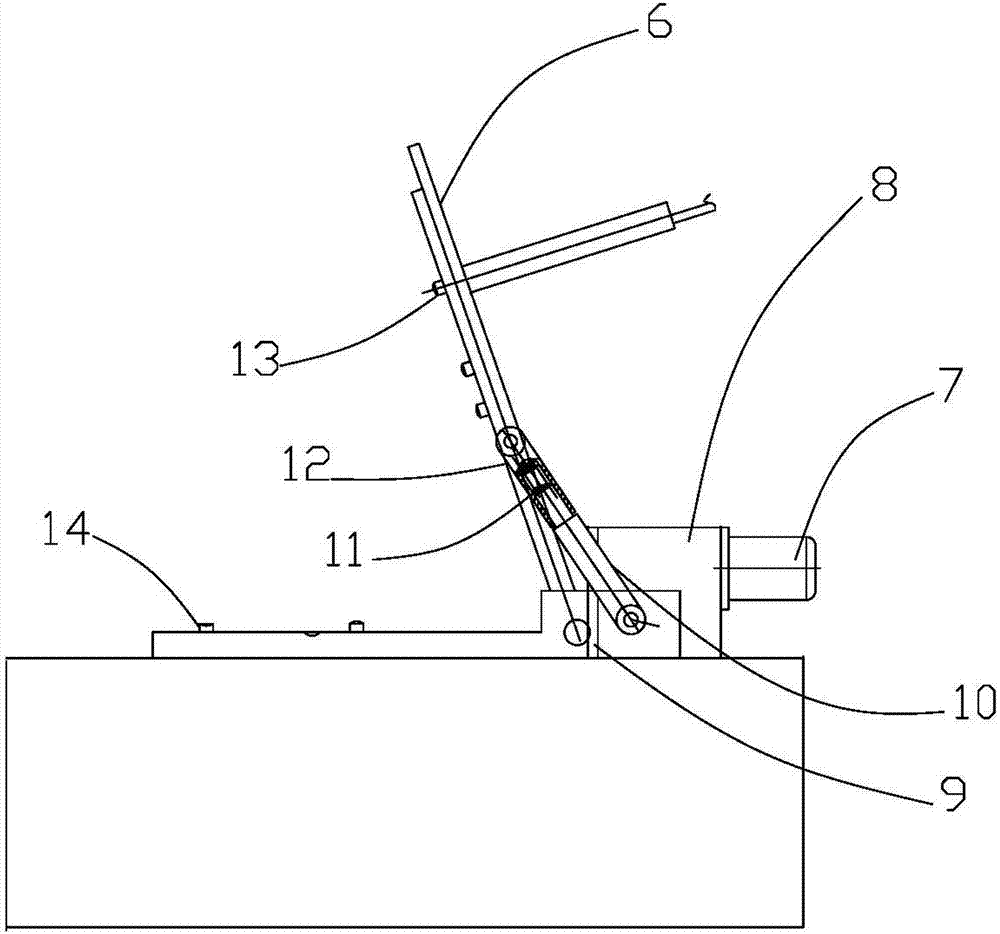

A dryland small particle seed full film covering hole planter

ActiveCN104025778BImprove germination rateImprove sowing qualitySeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringAgricultural machinery

The invention relates to agricultural machinery, in particular to a structure of a hole seeder. A full-film-covered hole planter for small-particle seeds in dry land, including a front frame, a rear frame, a suspension device, a film laying assembly, a hole planter assembly, and a soil covering assembly; a bulldozing board is arranged under the suspension device; The frame is equipped with a pressing roller, a film laying assembly and a hole seeder assembly, and the rear frame is equipped with a soil covering assembly and a soil scraping and film pressing device. The present invention is novel in design, compact in structure and strong in adaptability. In particular, it adopts a planter assembly with precise and adjustable sowing volume and sowing depth. The inner drum realizes the adjustment of the sowing rate and changes the position of the adjusting pin on the movable mouth to control the sowing depth; the bulldozer and pressure roller are equipped to ensure the reliability of the sowing depth, improve the germination rate and sowing quality of seeds, save seeds, and improve the quality of alfalfa Working conditions for mechanized harvesting of small particles of seeds such as , onions, and Chinese herbal medicines.

Owner:GANSU AGRI UNIV

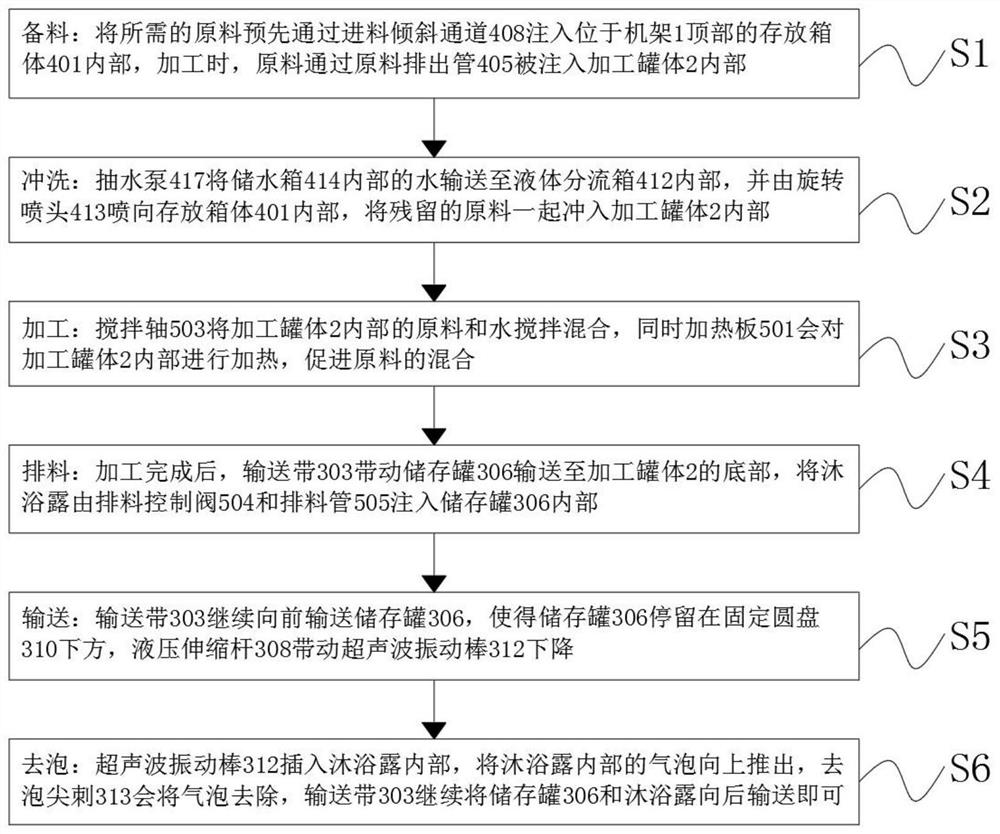

Shower gel containing natural plant components and preparation method thereof

ActiveCN113697752AScientific and reasonable structureEasy to useRotary stirring mixersHollow article cleaningShower gelEngineering

The invention discloses a preparation method of shower gel containing natural plant ingredients. The preparation method comprises the following steps that conveying is achieved: a storage tank is conveyed continuously forwards by a conveying belt, so that the storage tank stays below a fixing disc, and an ultrasonic vibration rod is driven to descend by a hydraulic telescopic rod. According to the preparation method of the shower gel containing the natural plant ingredients, after shower gel processing is finished, the shower gel is discharged and injected into the storage tank, the storage tank and the shower gel are conveyed backwards through a conveying shaft and the conveying belt, standing is needed for a certain time when shower gel processing is finished, and the interior of a processing tank can still keep a certain temperature by discharging the shower gel, heat in the storage tank cannot be lost, then a new raw material is injected to directly carry out next processing, the processing procedure of the shower gel can be continuously carried out, the waiting time of processing equipment is shortened, the working efficiency is improved, meanwhile, a positioning batten plays a role in positioning the storage tank, and it is ensured that the position of the storage tank cannot deviate in the conveying process.

Owner:亨特酒店用品(汕头)有限公司

A throwing device for automatic control ratio feeding

ActiveCN111214986BAccurate volume controlEasy to operateRotary stirring mixersTransportation and packagingAutomatic controlElectric machine

The invention discloses a throwing device for automatic ratio-controlled feeding, which comprises a base, a geared motor, a junction box and a third stepping motor, the top of the base is fixed with a mixing tank by bolts, and the lower surface of the mixing tank is welded There is a material distribution pipe, the outer surface of the material distribution pipe is evenly inserted with a feeding trough, the inner wall of the material distribution pipe is provided with a chute, and the inner side of the chute is provided with a material distribution mechanism, the material distribution pipe The lower surface is fixed with a second stepping motor by screws, the output end of the second stepping motor penetrates the lower surface of the material distribution pipe, the outer surface of the mixing bucket is fixed with a junction box by screws, and the mixing A proportioning cylinder is inserted on the upper surface of the barrel, and an observation window is provided through the outer surface of the front end of the proportioning cylinder, and the outer periphery of the observation window is bonded and fixed to the proportioning cylinder. Mechanism and carriage. The invention can automatically control the feeding ratio, realize precise control, is simple to operate, and is convenient for feeding in batches.

Owner:乐清众晟塑胶有限公司

An environmentally friendly silk quilt production process and device

ActiveCN111676522BEasy to produceIncrease productivityDrying solid materials without heatBlanketEngineeringAir blower

The invention discloses an environment-friendly silk quilt manufacturing process, comprising the following steps: breeding silkworms, placing silkworm cocoons on a baking tray and pushing them into an oven, baking the silkworm cocoons, setting the baking temperature at 85°C, and baking The time is set at 22min, the baked silkworm cocoons are put into the cocoon cooking mechanism, and the soda ash is added into the cocoon cooking mechanism through the feeding mechanism. This kind of environment-friendly silk quilt production process, through the cooperation of the second motor, the rotating shaft and the connecting rod, enables people to control the rotation of the output shaft of the second motor, so that the output shaft of the second motor drives the rotating shaft and the connecting rod to rotate, so that the The silk cotton pocket fixed on the clamping mechanism can be rotated accordingly to remove the moisture on the silk cotton pocket. After the moisture is removed, the silk cotton pocket is dried by the hot air generated by the hot air blower, so that the silk cotton pocket is put into the drying process. The inside of the drying box can be dehydrated and dried in sequence, which simplifies the production process, does not need to repeatedly pick and place the silk cotton pocket, and improves the production efficiency.

Owner:江西金铭丝绸有限公司

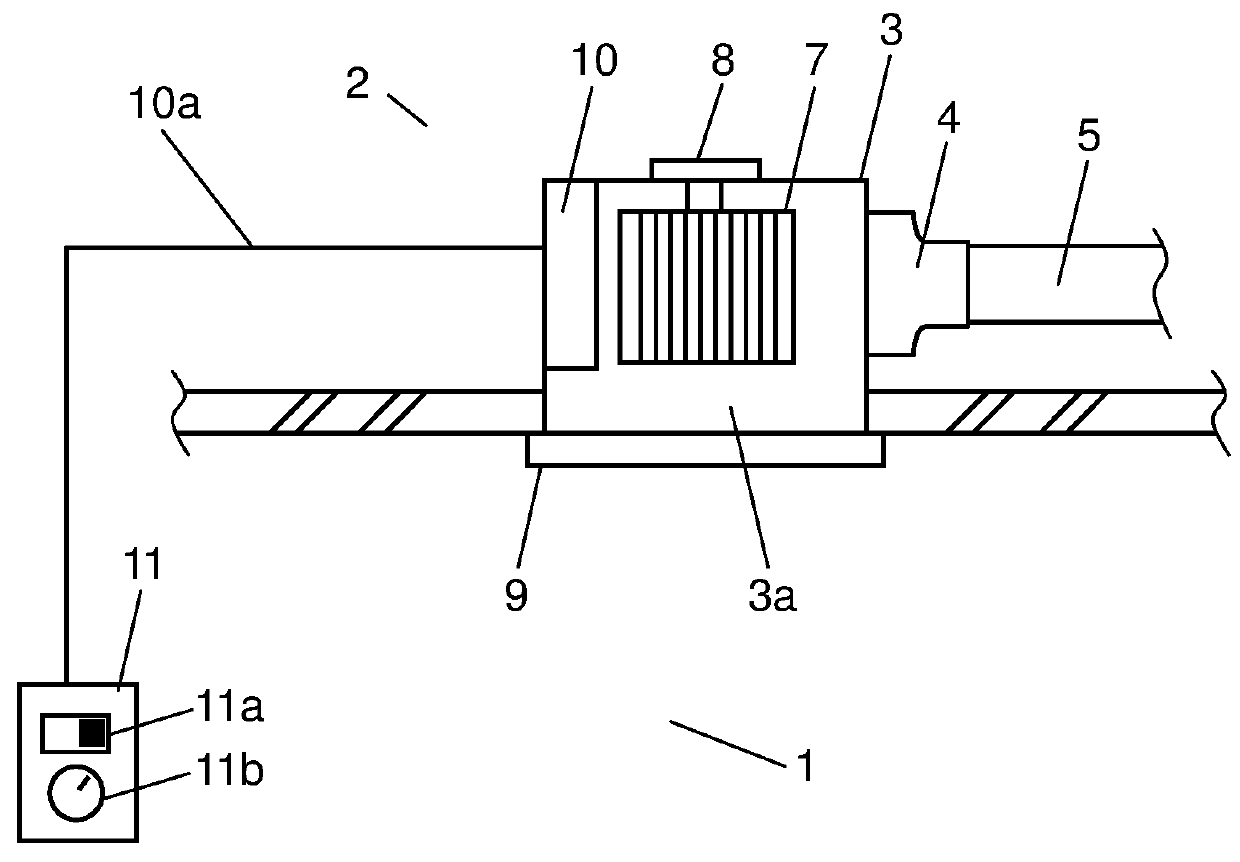

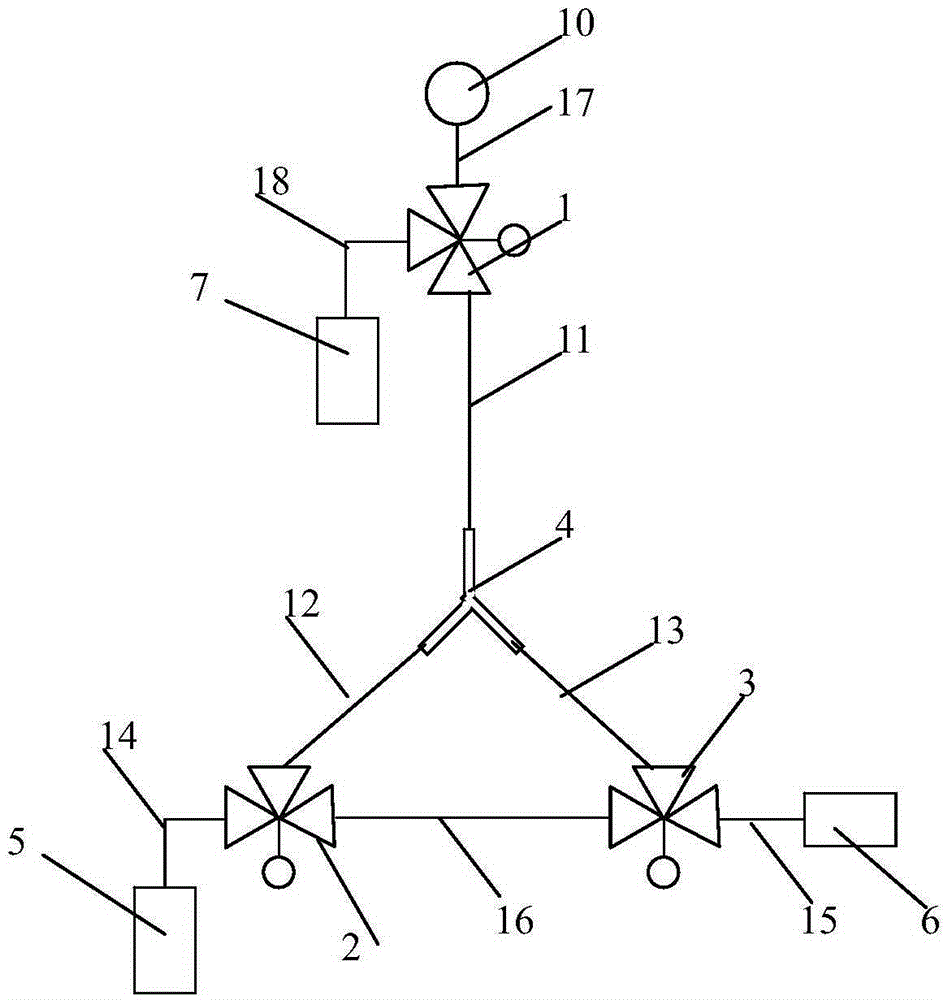

Liquid sampling system and control method thereof

ActiveCN103852587BAchieve precise quantitative controlAccurate volume controlMaterial analysisPositive pressureBottle

The invention discloses a liquid sample injection system which comprises a driving device with two-way driving capability, a first adjustment valve, a second three-way adjustment valve, a third three-way adjustment valve and a three-way connector, wherein three ends of the three-way connector are respectively connected with one valve port of each of the first adjustment valve, the second three-way adjustment valve and the third three-way adjustment valve through pipelines; one valve port of the second three-way adjustment valve is connected to a sample liquid bottle through a pick-up tube; one valve port of the third three-way adjustment valve is connected to an analysis instrument through a drain pipe; the rest of valve ports of the second three-way adjustment valve and the third three-way adjustment valve are communicated through a liquid storage pipe; the driving device and another valve port of the first adjustment valve are communicated through a fourth pipeline. The invention also discloses a control method of the liquid sample injection system. The sample injection system is simple in structure without complicate positive pressure driving sample injection structure, and the smooth-going performance of injection sample liquid flow is relatively high in the whole process.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Novel continuous feeding equipment for coating processing

InactiveCN113332917AAccurate volume controlPrecise ratioMixer accessoriesIndustrial engineeringProduction quality

The invention relates to the technical field of coatings, and discloses novel continuous feeding equipment for coating processing. The equipment comprises a mounting table, a dustproof shell is fixedly connected to the top of the mounting table, a feeding hole is formed in the side wall of the dustproof shell, a via hole is formed in the top of the dustproof shell, and a dust suction pipe is fixedly connected to the inner wall of the via hole. And one end of the dust suction pipe is fixedly connected with an air draft dust suction machine, the top of the mounting table is fixedly connected with supporting legs, and the side walls of the supporting legs are fixedly connected with positioning blocks. According to the novel continuous feeding equipment for coating processing, the purpose of accurately controlling the coating feeding amount is achieved, the problem that common continuous feeding equipment is not particularly accurate in control over the coating feeding amount is solved, a worker can accurately control the coating proportion, the situation that the coating is too much or too little is avoided, the production quality of the coating is improved, the production cost of a factory is reduced, and the requirements of the factory on yield and quality are met.

Owner:辰溪县时代巨媒广告有限公司

Ultramicro nucleic acid protein analyzer automatic sample feeding detection device

InactiveCN106370874AImprove efficiencyImprove accuracyMaterial analysisAutomatic controlAnalysis sample

The invention relates to an ultramicro nucleic acid protein analyzer automatic sample feeding detection device. Efficiency and accuracy of detection and analysis of nucleic acid protein are greatly improved. According to the scheme, the device comprises a probe control mechanism, a cleaning mechanism, a sample dispensing mechanism and a sample sending mechanism. The probe control mechanism is controlled by a stepping motor to achieve vertical swinging of an upper detection probe. The cleaning mechanism is controlled by a stepping motor to drive a fire mandrel to rotate, cleaning paper on a second mandrel is wound around the first mandrel, and then the upper detection probe and a lower detection probe are cleaned. The sample dispensing mechanism injects samples in a sample gun to the lower detection probe, and the sample sending mechanism drives the cleaning mechanism and the sample dispensing mechanism to horizontally move. The volume control of the detection and analysis samples is more precise, an automatic control device is used, automatic sample feeding detection is achieved, efficiency and accuracy of detection and analysis of nucleic acid protein are obviously improved, inspection operation is simple, and unnecessary labor of relevant researcher is reduced.

Owner:河南省人口和计划生育科学技术研究院

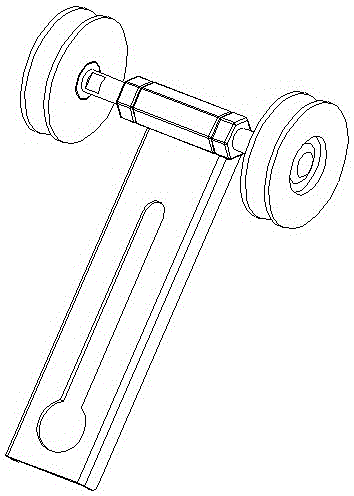

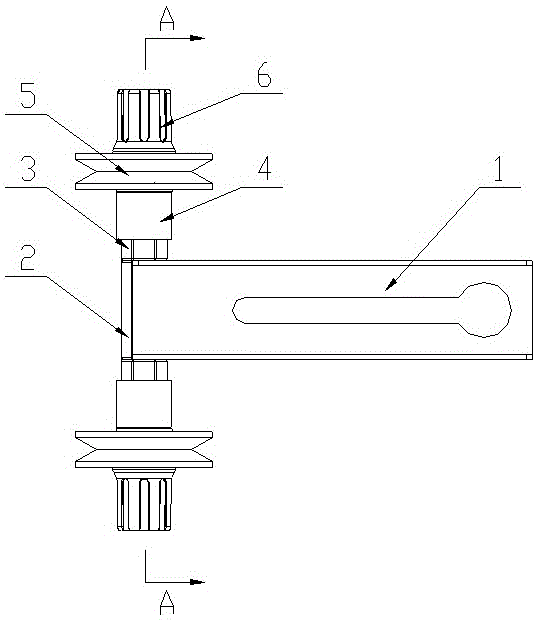

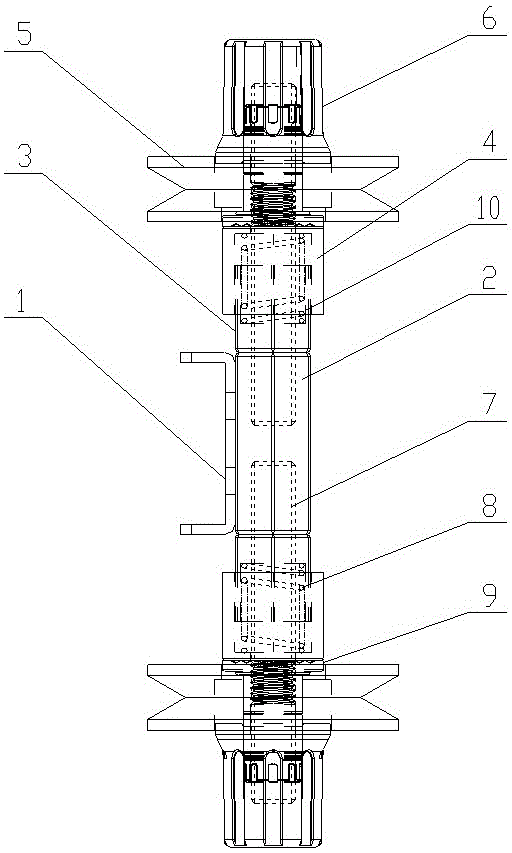

Godet wheel assembly

The invention relates to a godet wheel assembly and belongs to the technical field of spinning accessories. The godet wheel assembly comprises a support (1). One end of the support (1) is provided with a connecting piece (2), and the left side and the right side of the connecting piece (2) are provided with lead screws (7) which are connected with the connecting piece (2) through threads. Each lead screw (7) is provided with a locating nut (3), a rotation stopping part (4), an adjusting part (9) and an adjusting knob (6) from inside to outside in sequence, wherein godet wheels (5) are installed on the adjusting parts (9) which are connected with the lead screws (7) through threads. The godet wheel assembly is simple in structure and convenient to adjust, and the adjusting variable can be accurately controlled.

Owner:孔锋

Antibacterial and antifouling shirt surface coating device

ActiveCN114427147AAvoid the situation of spraying in advanceGuaranteed to closeTextile treatment by spraying/projectingTextile treatment carriersAnti bacterialMechanical engineering

The invention relates to an antibacterial and anti-fouling shirt surface coating device which comprises an outer frame, two conveying type coating mechanisms, an overturning positioning mechanism and a dustproof cover, the left end and the right end of the outer frame are each provided with one conveying type coating mechanism, the dustproof cover covers the conveying type coating mechanisms, and the dustproof cover is buckled on the outer side wall of the outer frame. And a turnover positioning mechanism is mounted in the outer frame. The device can solve the problems that the spraying amount is difficult to control by manual spraying, a spraying track from top to bottom is selected on the premise that the spraying amount is difficult to control, so that the sprayed anti-fouling finishing agent completely falls onto the fabric, the spraying of each area of the fabric is uneven, and during spraying, part of the fabric area is pressed and is difficult to directly contact with the finishing agent, so that the spraying effect is poor. The part of the fabric is not coated due to the fact that the part of the fabric is not coated, the part of the fabric needs to be subjected to supplementary coating subsequently, but the situation that the supplementary coating peripheral area is sprayed again is prone to occurring in supplementary coating.

Owner:安徽豹子头服饰股份有限公司

An automatic sample detection device for an ultra-trace nucleic acid and protein analyzer

InactiveCN106370874BImprove efficiencyImprove accuracyMaterial analysisAutomatic controlAnalysis sample

The invention relates to an ultramicro nucleic acid protein analyzer automatic sample feeding detection device. Efficiency and accuracy of detection and analysis of nucleic acid protein are greatly improved. According to the scheme, the device comprises a probe control mechanism, a cleaning mechanism, a sample dispensing mechanism and a sample sending mechanism. The probe control mechanism is controlled by a stepping motor to achieve vertical swinging of an upper detection probe. The cleaning mechanism is controlled by a stepping motor to drive a fire mandrel to rotate, cleaning paper on a second mandrel is wound around the first mandrel, and then the upper detection probe and a lower detection probe are cleaned. The sample dispensing mechanism injects samples in a sample gun to the lower detection probe, and the sample sending mechanism drives the cleaning mechanism and the sample dispensing mechanism to horizontally move. The volume control of the detection and analysis samples is more precise, an automatic control device is used, automatic sample feeding detection is achieved, efficiency and accuracy of detection and analysis of nucleic acid protein are obviously improved, inspection operation is simple, and unnecessary labor of relevant researcher is reduced.

Owner:河南省人口和计划生育科学技术研究院

In-situ concentration device and method for phytoplankton sample

ActiveCN113008656AOvercoming Density VariationsReduce lossesPreparing sample for investigationAgriculture gas emission reductionPhysical chemistryEngineering

The invention discloses an in-situ concentration device and method for a phytoplankton sample. The device comprises a concentration device and a metering device, the concentration device comprises a cylinder body, a one-way valve device and cylinder body bolting silk; the metering device comprises a connecting rod, a positioning rod, a slow descending device, a volume positioner, a base and a weight. By utilizing the device and method, in-situ concentration can be directly realized in the sample bottle, the problem that the density of the sample is inevitably changed because the sample needs to be poured into a concentration device and then transferred out after being concentrated by other devices is solved, and the loss of the sample and the error are fundamentally reduced.

Owner:NORTH CHINA SEA ENVIRONMENTAL MONITORING CENT OF STATE OCEANIC ADMINISTATION

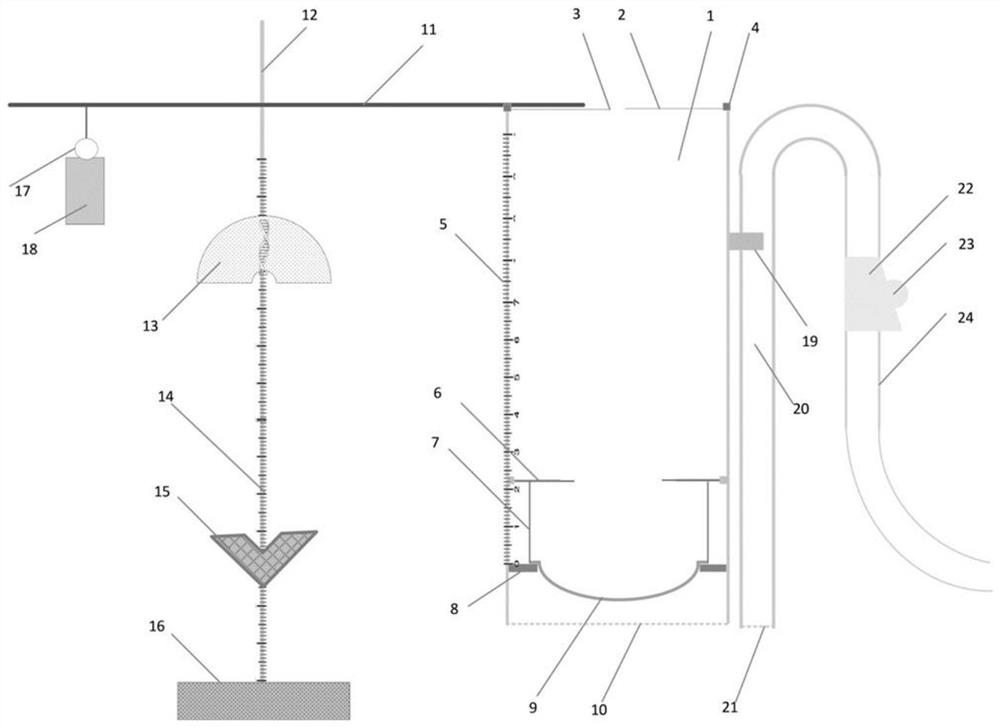

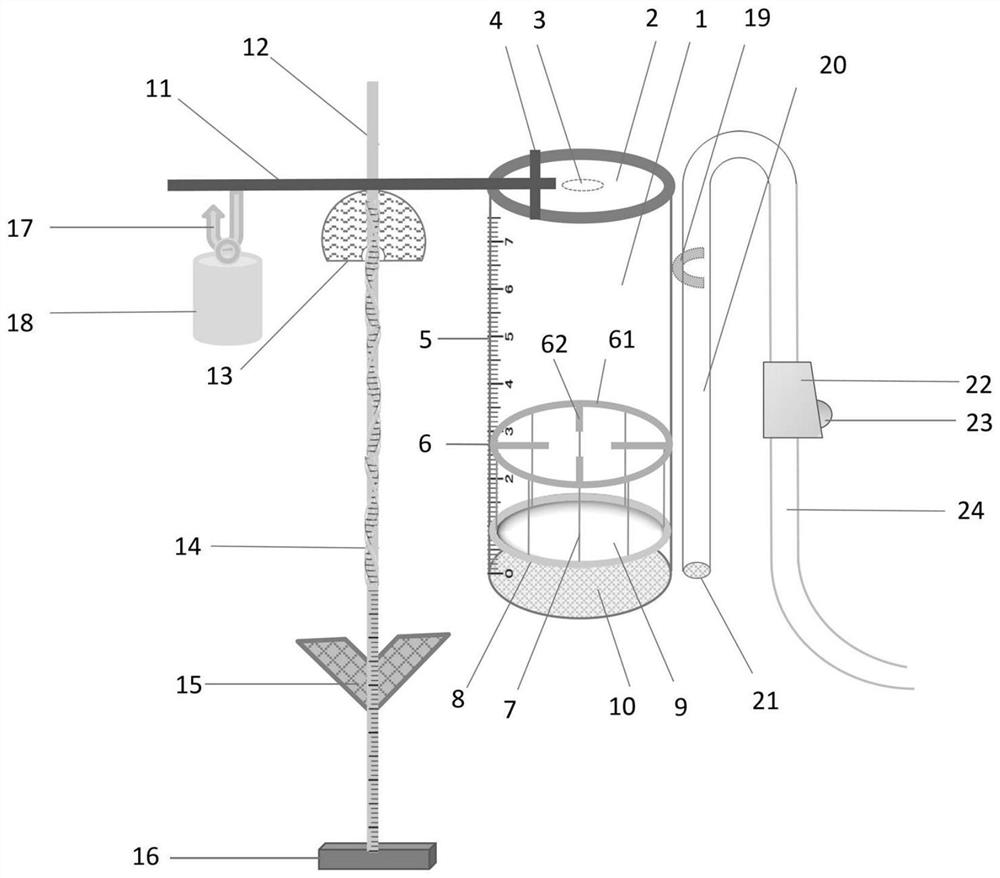

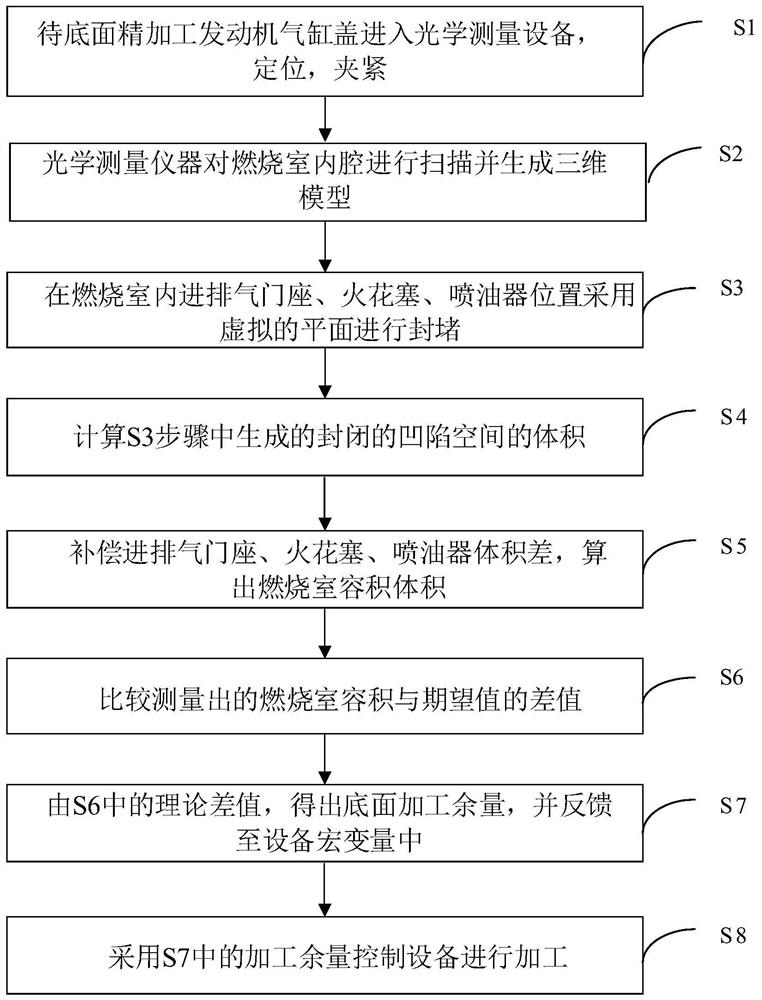

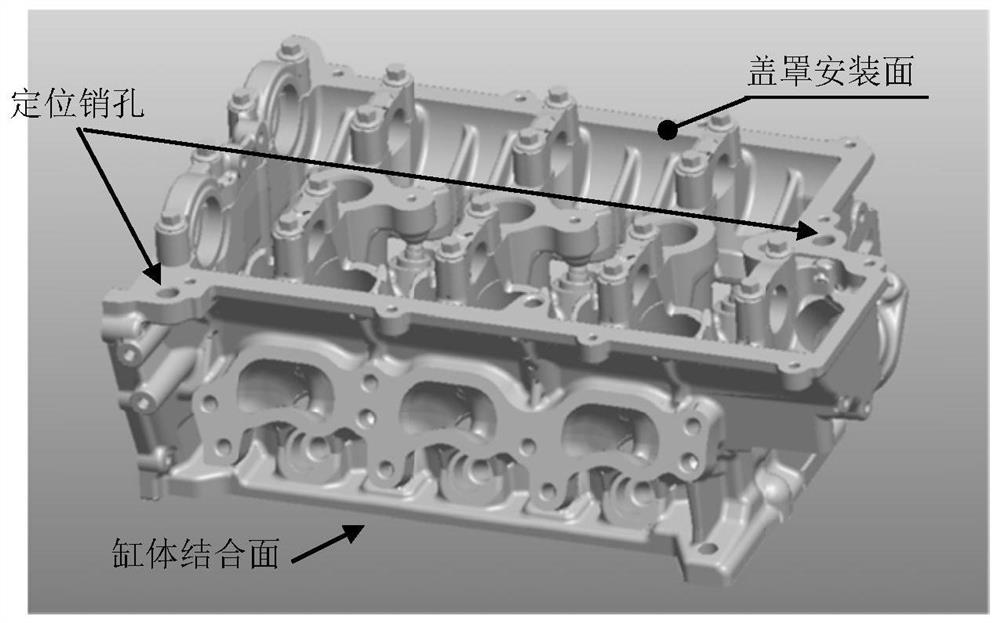

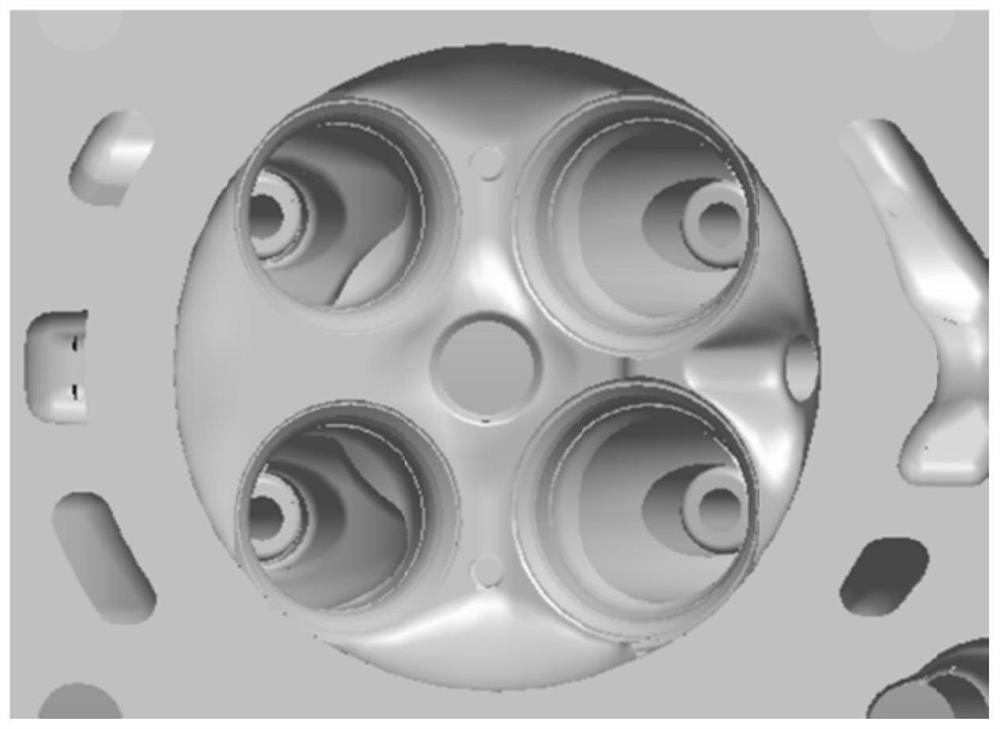

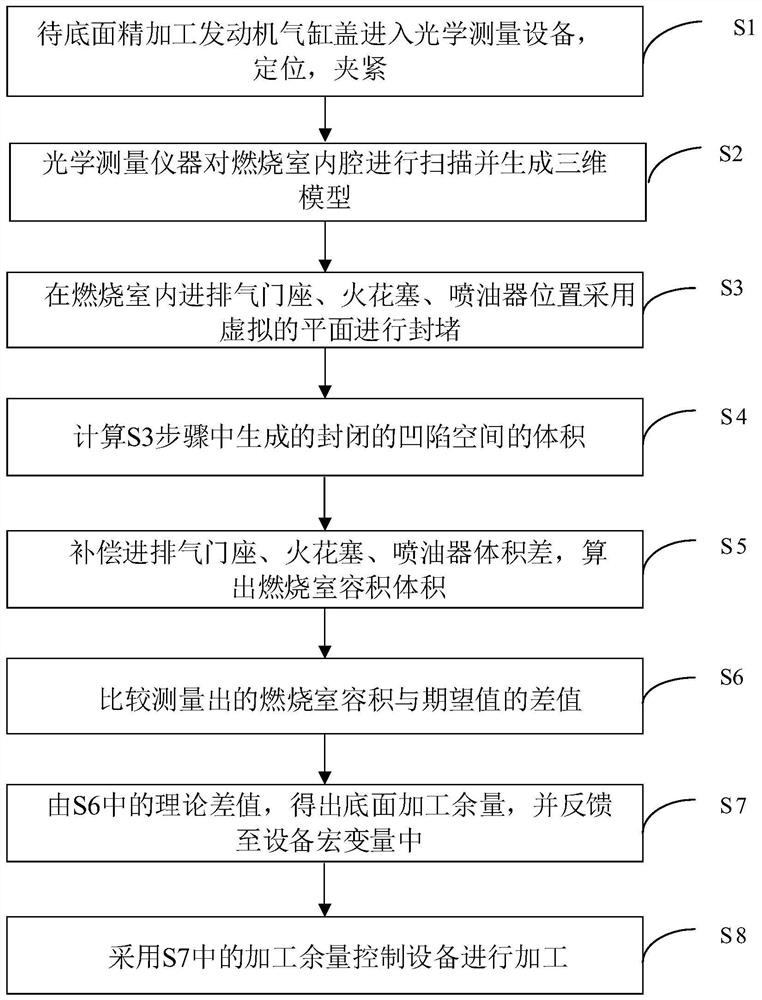

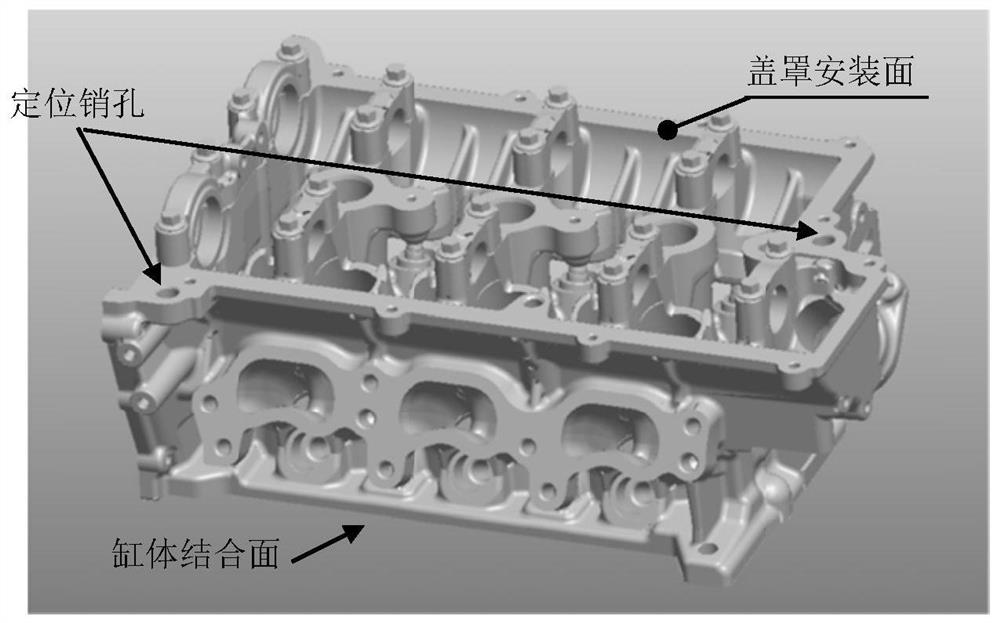

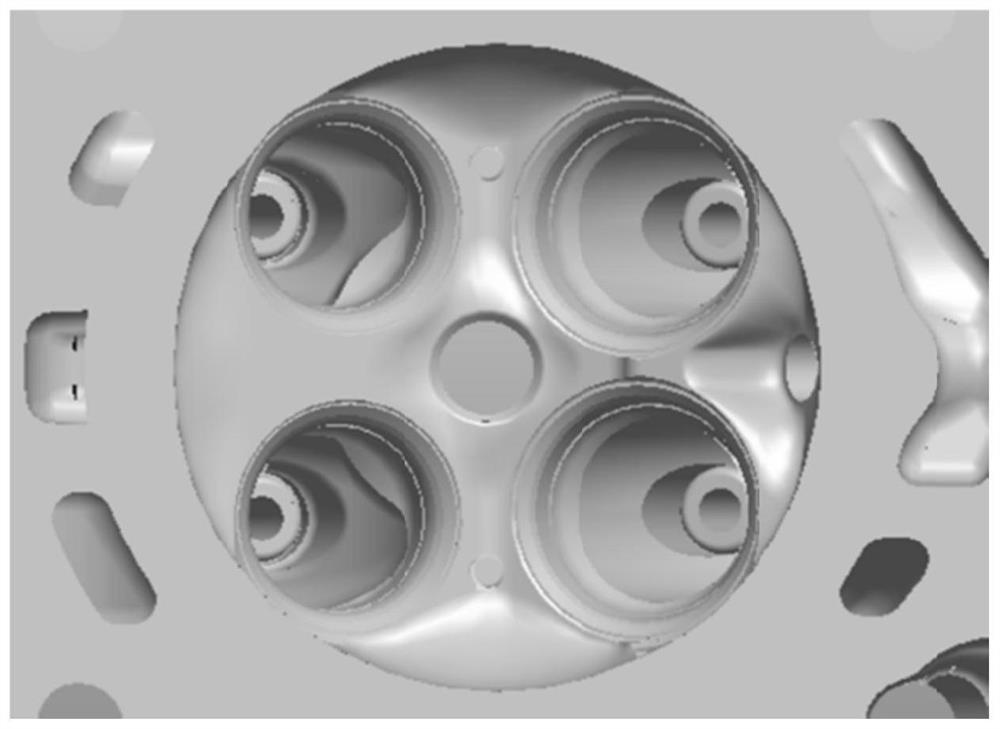

Optics and feedback based volume machining control method for combustion chamber of engine cylinder cover

ActiveCN112276174AVolume controlAccurate volume controlUsing optical meansMilling equipment detailsCombustion chamberOptical scanning

The invention discloses an optics and feedback based volume machining control method for a combustion chamber of an engine cylinder cover. The method comprises the following steps: performing opticalscanning on a combustion chamber of an engine cylinder cover with a cylinder body combination surface to be finely machined, and generating a three-dimensional data model; blocking a valve seat surface, a fuel injector hole and a spark plug hole in the combustion chamber by adopting a virtual plane in the data model, forming a closed space with the cylinder body combination surface of the engine cylinder cover, and calculating the volume of the closed space; calculating plugging volume difference among the virtual plugging plane, an actual valve, a fuel injector and a spark plug as a compensation value of the volume of the closed space to obtain the volume value of the combustion chamber; and calculating a difference value between the combustion chamber volume and the combustion chamber volume target value, and calculating allowance, needing finish milling, of the cylinder body combination surface of the engine cylinder cover according to the difference value and inputting the allowance into macro variables of machining equipment. According to the invention, the volume of the combustion chamber of the cylinder cover to be finely machined can be accurately measured, and the volume of the combustion chamber of the engine cylinder cover can be accurately controlled.

Owner:DONGFENG MOTOR CORP HUBEI

Machining and Control Method of Engine Cylinder Head Combustion Chamber Volume Based on Optics and Feedback

ActiveCN112276174BVolume controlAccurate volume controlUsing optical meansMilling equipment detailsCombustion chamberEngineering

The invention discloses an engine cylinder head combustion chamber volume processing control method based on optical measurement and feedback mechanism, which performs optical scanning on the combustion chamber of the engine cylinder head on the joint surface of the cylinder block to be finished, and generates a three-dimensional data model; in the data model Use a virtual plane to block the valve seat surface, fuel injector hole, spark plug hole in the combustion chamber, form a closed space with the cylinder block joint surface of the engine cylinder head, and calculate the volume of the closed space; calculate the virtual plugging plane and the actual The volume difference of valves, fuel injectors, and spark plugs is used as a compensation value for the volume of the closed space to obtain the volume of the combustion chamber; calculate the difference between the volume of the combustion chamber and the target value of the volume of the combustion chamber, and calculate the cylinder head of the engine according to the difference. The body joint surface requires a finishing allowance, which is input into the macro variables of the machining equipment. The invention can accurately measure the volume of the combustion chamber of the cylinder head to be finished, and accurately control the volume of the combustion chamber of the cylinder head of the engine.

Owner:DONGFENG MOTOR CORP HUBEI

A cylinder-type air pistol

ActiveCN104034206BEffort-saving pullSimple structureFiring/trigger mechanismsSighting devicesGas cylinderInlet valve

The invention belongs to the field of air guns and particularly relates to an air cylinder type air pistol. The air cylinder type air pistol comprises a trigger mechanism, an air inlet device, an air outlet device, a loaded linkage mechanism, a sight device and a front sight device, wherein the air inlet device comprises an air cylinder, wherein the air cylinder is mounted in an air pipe through a locking sleeve, and the air outlet end of the air cylinder is connected with an air inlet structure; the air inlet structure comprises an air inlet valve, and a pricking pin is arranged in the air inlet valve; the air outlet device comprises a valve body component, one end of the valve body component is connected with the pricking pin, and the other end of the valve body component is abutted against an air outlet. The air cylinder type air pistol has the benefits that the operation is convenient, the structure is simple and practical, and a method for manually pressing air into an air chamber in the air gun during a shooting is eliminated.

Owner:SHAOXING LINGFENG AIR GUN MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com