Settling separation device for phytoplankton

A sedimentation separation and phytoplankton technology, which is applied to sedimentation separation, feeding/discharging devices of sedimentation tanks, sedimentation tanks, etc. It is convenient for constant volume work, not easy to be damaged, and the effect of accurate volume control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

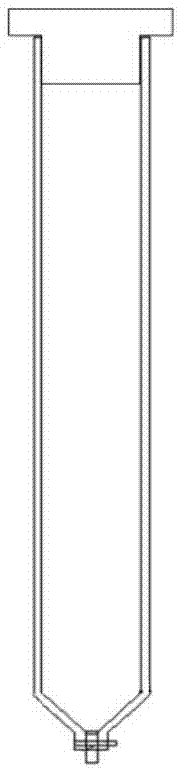

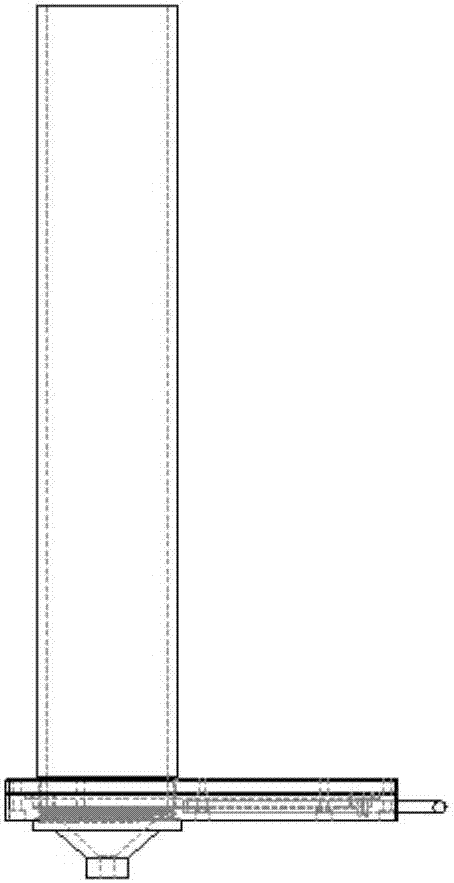

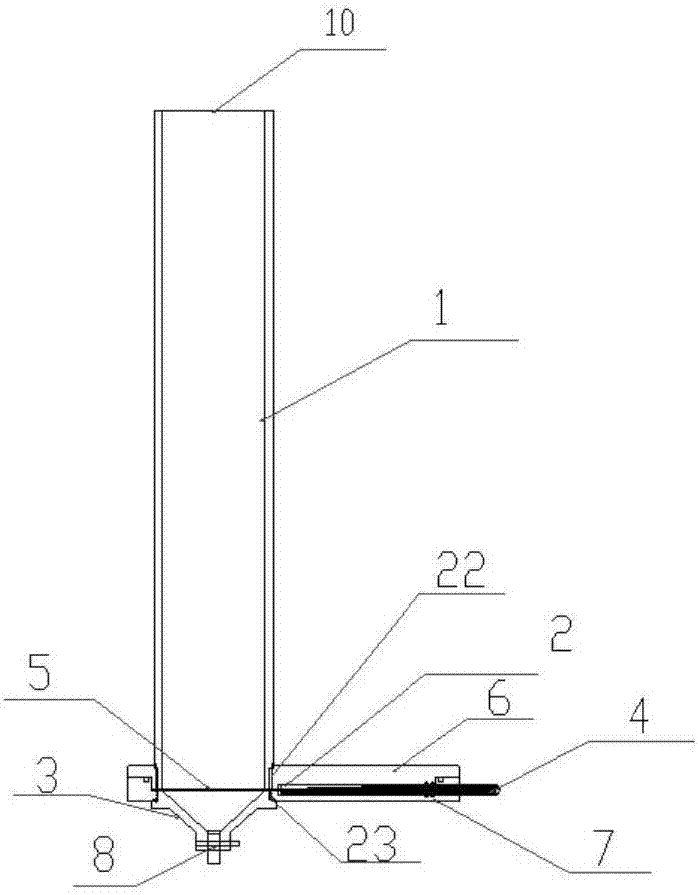

[0034] A phytoplankton sedimentation and separation device, comprising an agley casing 1, and an upper cover plate 6 and a lower cover plate 7 fixed together, the upper cover plate 6 is provided with an upper cover plate hole 22, and the upper cover plate hole 22 is connected with the The bottom end of the Yagley casing 1 is connected, the top surface of the lower cover 7 is provided with a partition chute 16, and the bottom of the partition chute 16 corresponds to the position of the upper cover hole 22, and the lower cover hole 23 is opened. , the lower cover plate hole 23 is connected to the top of the sedimentation cup 3, and the bottom of the sedimentation cup 3 is provided with a drain valve 8,

[0035] The bottom surface of the upper cover plate 6 is provided with an upper cover plate ring groove 28, and the upper cover plate ring groove 28 is embedded with an upper cover plate sealing ring 25, and the upper cover plate hole 22 is located in the ring of the upper cover p...

Embodiment 2

[0044] In this embodiment, the Yagly sleeve 1 is cylindrical in shape, made of transparent Yagly material, has an outer diameter of 70mm, an inner diameter of 50mm, a volume of 1.5L, and a maximum scale of 1.5L. The bottom end of the Yagly casing 1 is connected to the hole 22 of the upper cover plate through threads, and the outer thread 20 of the casing at the bottom end of the Yagly casing 1 is M68×1.5, which is used to connect with the inner thread of the upper cover plate hole 22 of the upper cover plate. 21 matching connections.

[0045] The separation device 2 includes an upper cover plate 6 and a lower cover plate 7, the upper cover plate 6 and the lower cover plate 7 are two cuboid stainless steel cover plates, the upper cover plate 6 and the lower cover plate 7 are tightened by 10 M4 cover plate screws 12 . The separation partition 5 realizes the sealing between the Yagley casing 1 and the settling cup 3 through the upper cover sealing ring 25 and the lower cover sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com