Chinese wolfberry fruit automatic cleaning production line and working method thereof

An automatic cleaning and production line technology, applied in application, food processing, food science and other directions, can solve the problems of unfavorable industrial production, high labor intensity of workers, low production efficiency, etc., and achieve high degree of automation, low labor cost, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

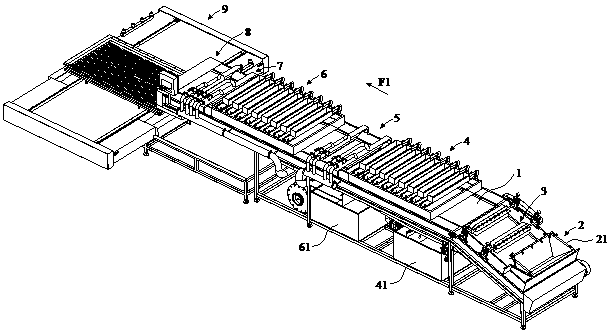

[0037] figure 1 It is a structural schematic diagram of the wolfberry automatic cleaning production line of the present invention (excluding the pre-cleaning station).

[0038] Such as figure 1 As shown, the present embodiment 1 provides a kind of Lycium barbarum automatic cleaning production line, comprises: the first conveying device 1 and cleaning station 4; Described first conveying device 1 is suitable for the wolfberry particle is transported to cleaning station 4, to clean Goji berry granules are cleaned.

[0039] Specifically, the first conveying device 1 presses figure 1 Move in the F1 direction.

[0040] The wolfberry automatic cleaning production line also includes a feeding station 2; the feeding station 2 includes: a feeding funnel 21 and a vibrating device; the wolfberry particles are suitable for falling onto the first conveying device 1 through the feeding funnel 21 , then the wolfberry particles are transported to the cleaning station 4 and the dewaxing st...

Embodiment 2

[0071] On the basis of embodiment 1, this embodiment 2 provides a working method of an automatic wolfberry cleaning production line, and the wolfberry automatic cleaning production line is suitable for automatic cleaning of wolfberry.

[0072] The structure and related working principles of the wolfberry automatic cleaning production line have been described in detail in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com