Method and device for optimizing installation position of direct-current GIL particle trap

A technology of installation location and optimization method, applied in design optimization/simulation, instrumentation, calculation, etc., can solve the problems of GIL insulation breakdown, threat to power safety and reliability, etc., to save construction costs and avoid a large number of repetitive experiments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

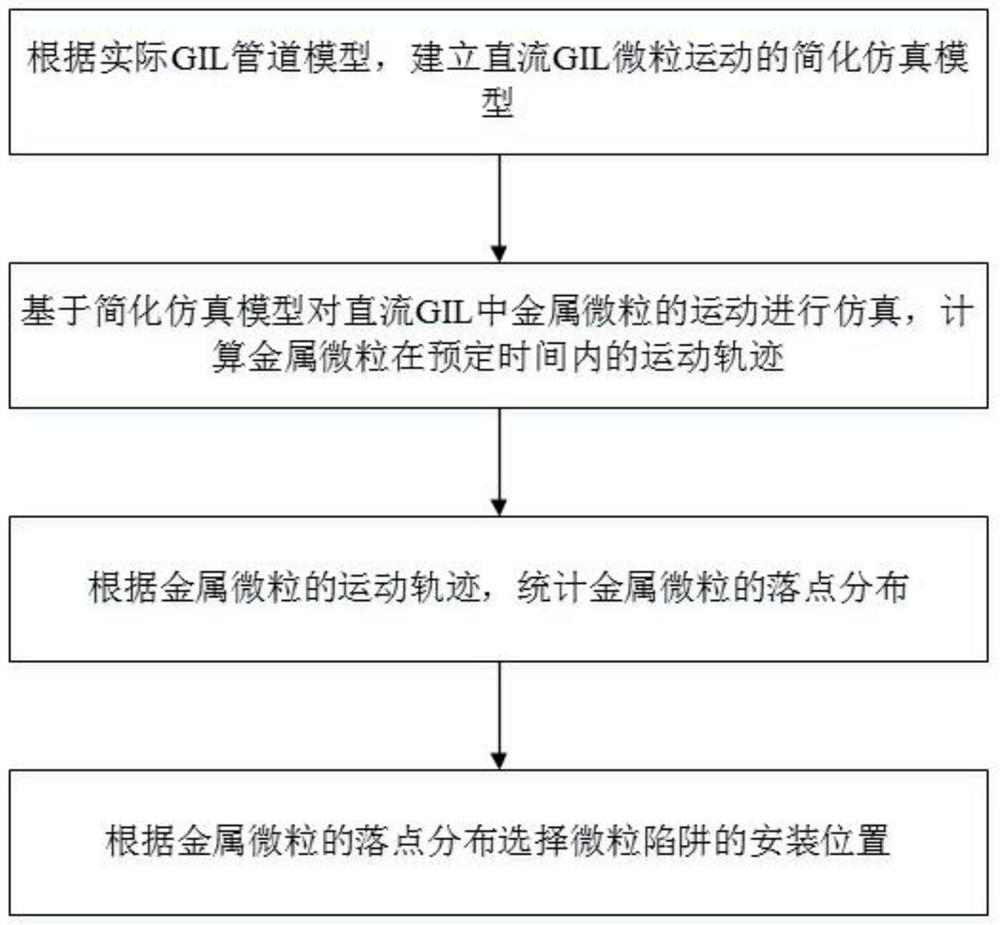

[0048] Such as figure 1 As shown, the embodiment of the present invention provides a method for optimizing the installation position of the DC GIL particle trap, using a computer to simulate and calculate the distribution of the DC GIL metal particles, and calculate the installation position of the particle trap according to the simulation results. Adjustment, specifically includes the following steps:

[0049] Step 1: Establish a suitable simplified simulation model for the movement of DC GIL particles based on the actual DC GIL pipeline model. The simplified simulation model specifically includes: GIL pipeline size, gas parameters, metal particle material, metal particle size, insulator model, etc., and determined according to relevant parameters The force equation and motion state equation of metal particles.

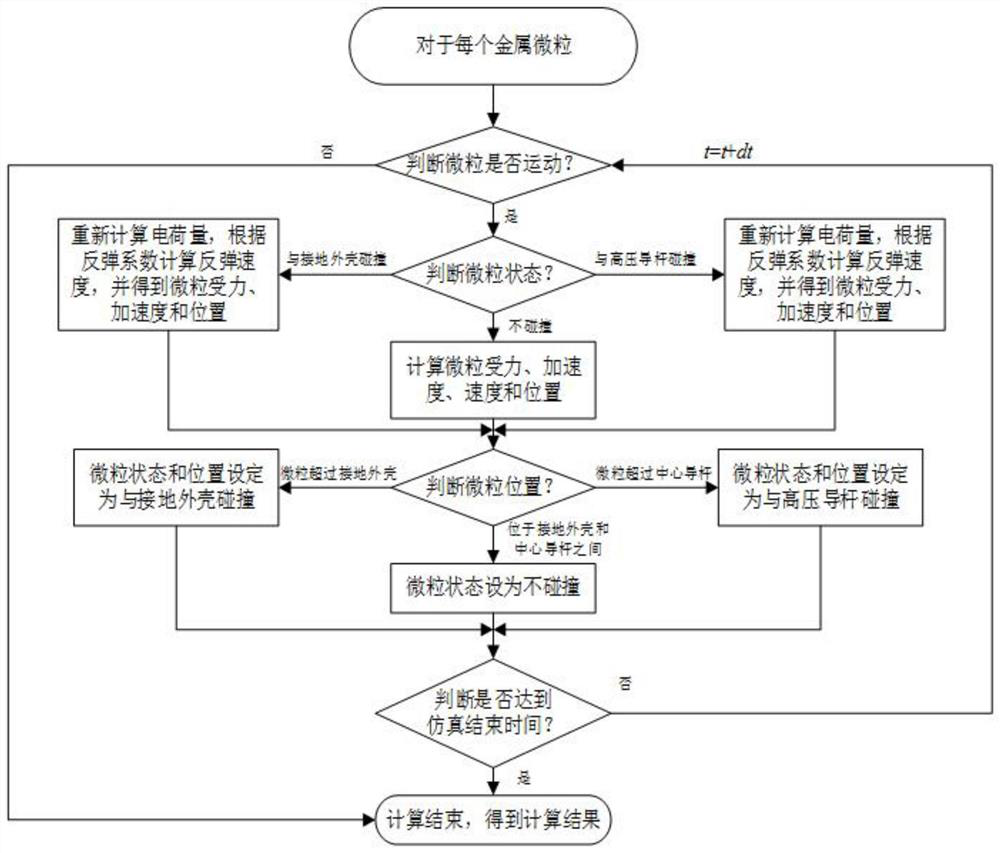

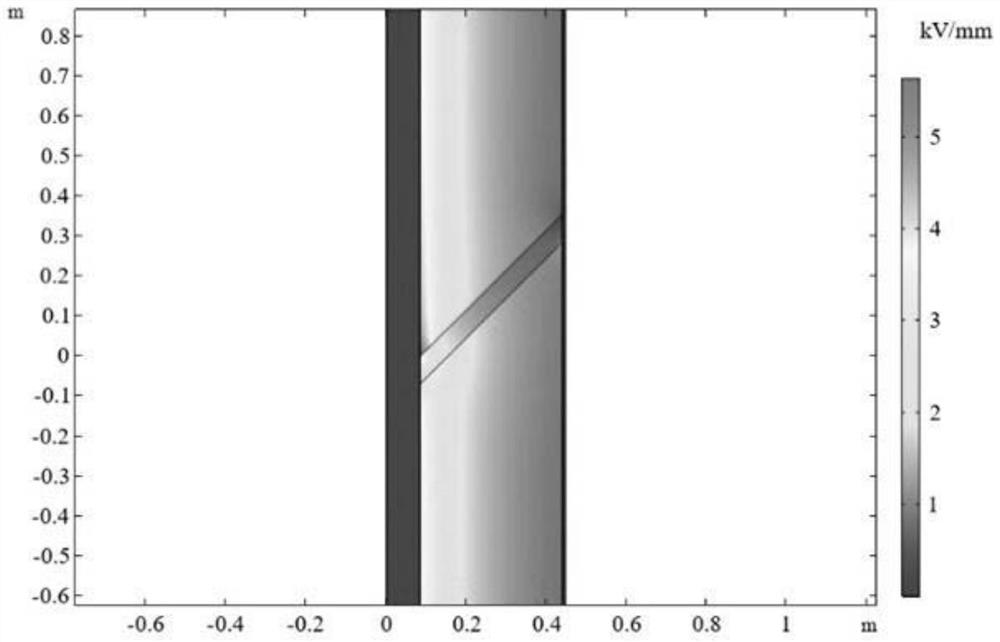

[0050] Among them, in the simplified simulation model, the gravity, buoyancy, Coulomb force, and air resistance experienced by the charged metal particles with a ra...

Embodiment 2

[0080] An embodiment of the present invention provides a device for optimizing the installation position of a particle trap, including the following modules:

[0081] The model building block is used to establish a simplified simulation model of DC GIL particle movement based on the actual GIL pipeline model;

[0082] The simulation calculation module is used to simulate the movement of metal particles in the DC GIL based on the simplified simulation model, and calculate the movement trajectory of the metal particles within a predetermined time;

[0083] The distribution statistics module is used to count the drop point distribution of the metal particles according to the movement trajectory of the metal particles;

[0084] The position selecting module is used for selecting a suitable installation position of the particle trap according to the distribution of metal particle falling points.

Embodiment 3

[0086] An embodiment of the present invention provides a device for optimizing the installation position of a particle trap, which is characterized in that it includes a processor and a storage medium;

[0087] The storage medium is used to store instructions;

[0088] The processor is configured to operate according to the instructions to execute the steps of any optimization method in the first embodiment.

[0089] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com