Scissors type integral cutter structure and printing device

A printing device and scissor-type technology, applied in the printing device, printing and other directions, can solve the problems of short life, the fixed blade and the movable blade are prone to damage, etc., and achieve the effect of improving the service life, facilitating the installation location and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

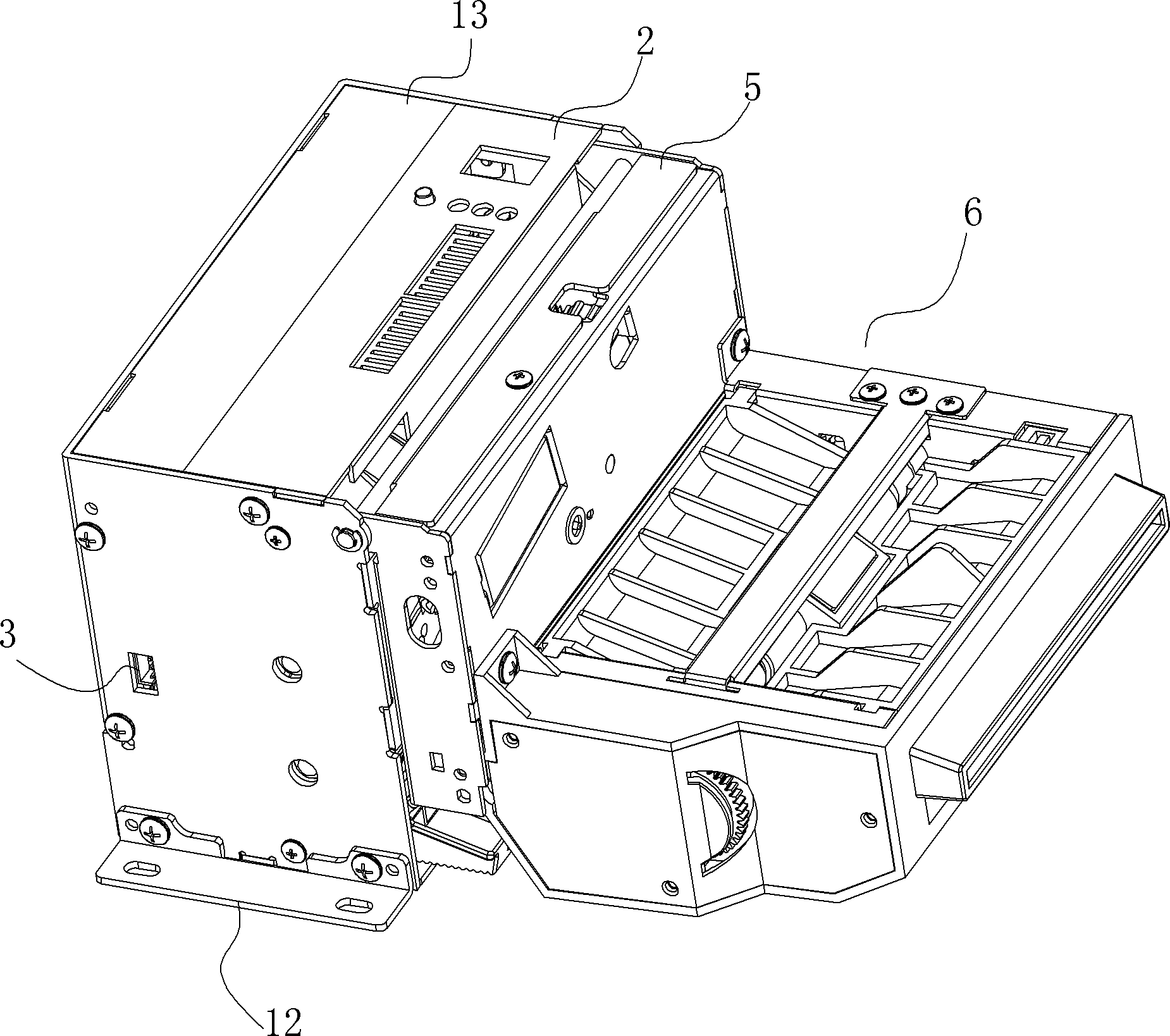

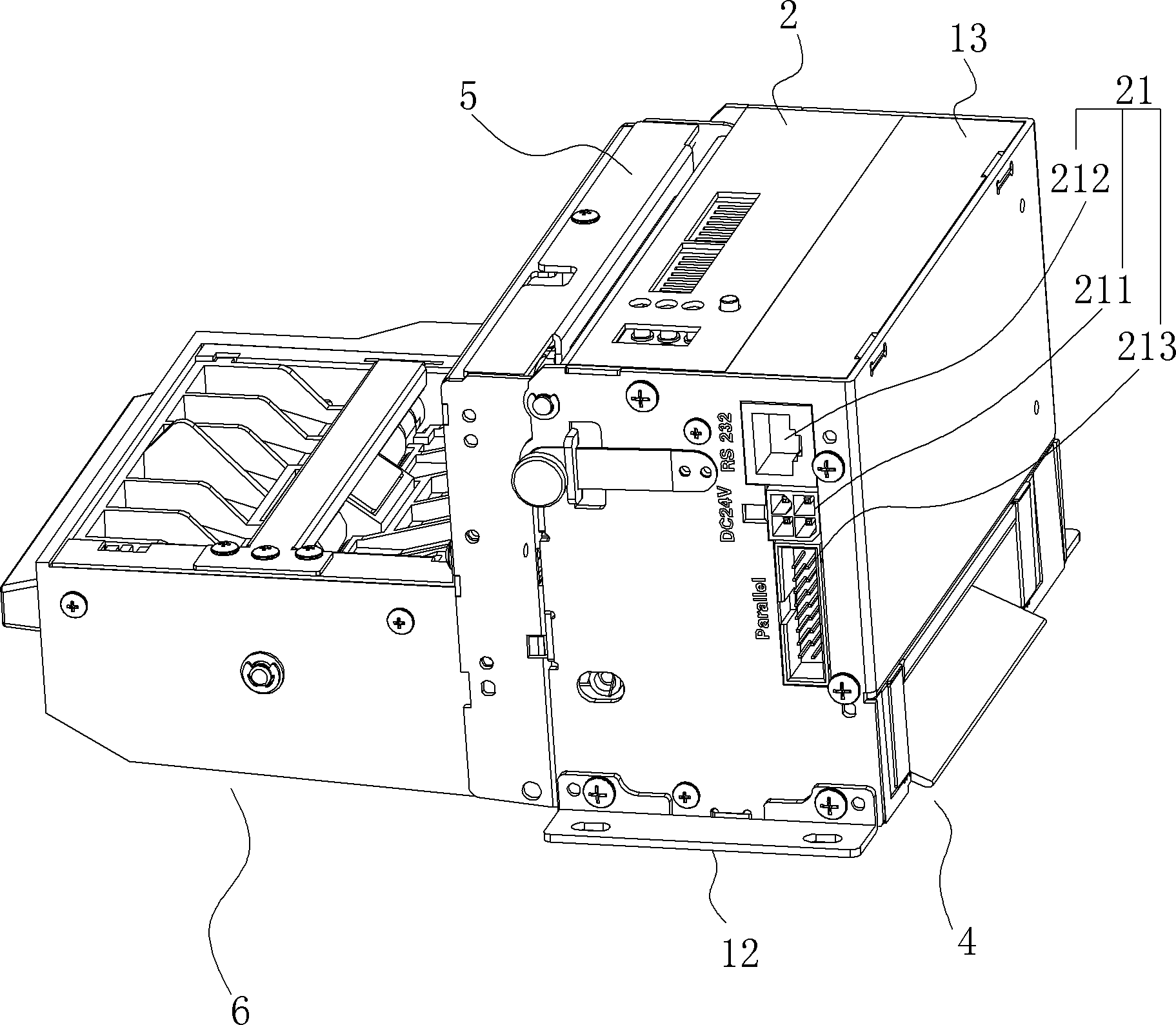

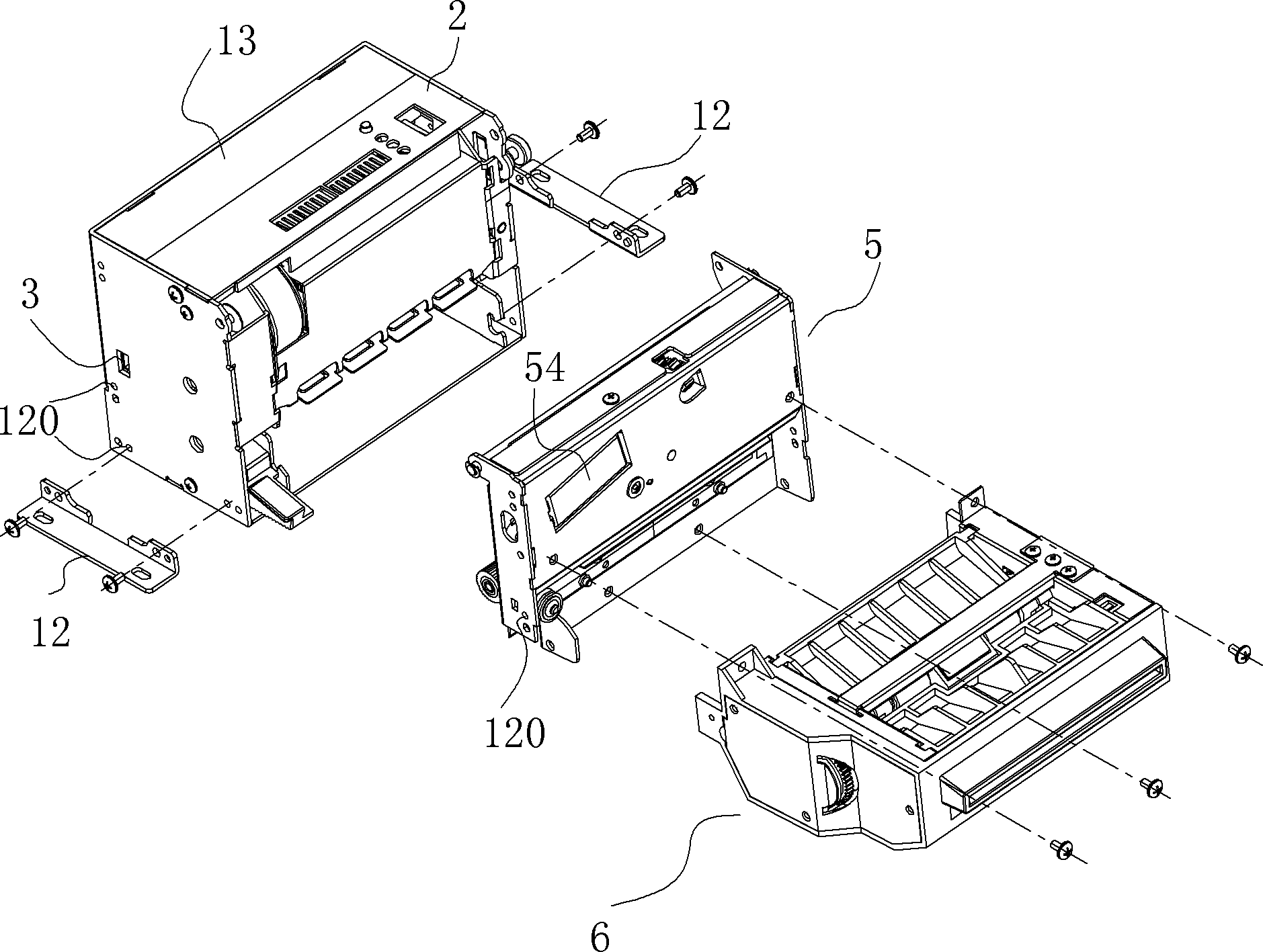

[0068] Such as Figure 6 to Figure 7 Shown is the structural diagram of the scissors-type integrated cutter structure of the present invention, wherein the cutter assembly 5 includes a paper cutting motor 54 fixedly connected to the cutter bracket 51; The movable blade 522 and the pin shaft 523 for connecting the movable blade 522 and the fixed blade 521; the fixed blade 521 is fixedly connected with the cutter bracket 51; the movable blade 522 is provided with a fixed end 5221 hinged with the pin shaft 523, 522 is also provided with the chute 5222 that is connected with paper cutting motor 54; shown in the figure). Wherein the upper end of pin shaft 523 is provided with the stage clip 524 that produces pretightening force to movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com