Condensation type RTV silicone rubber composition with matte surface, its preparation method and application

A technology of silicone rubber composition and condensed silicone rubber, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of long matte time and high gloss, and achieve short matte time, good storage stability, and matte Excellent effect of light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

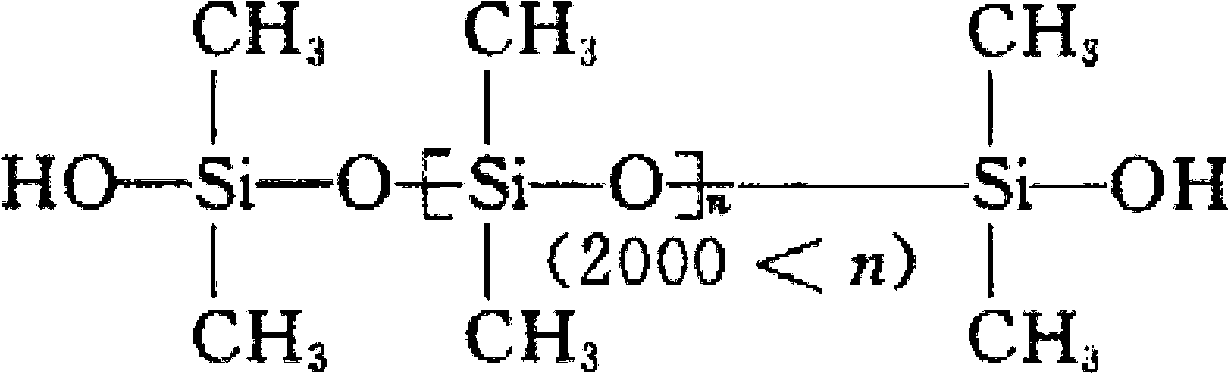

Method used

Image

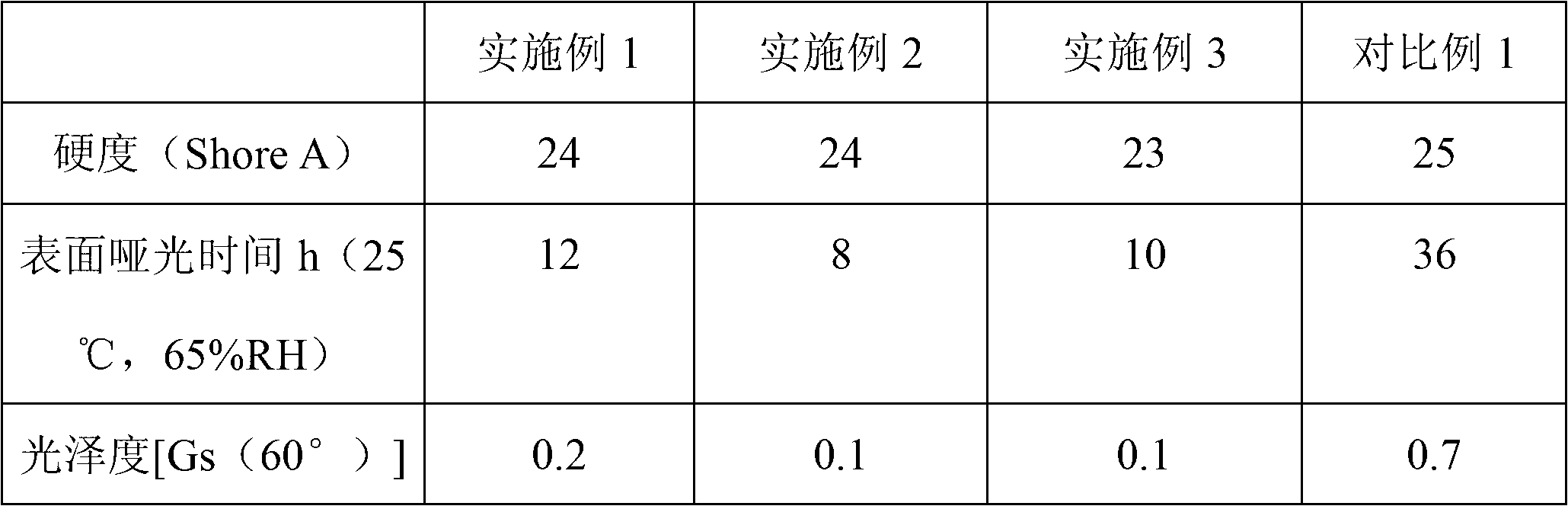

Examples

Embodiment 1

[0049] A matte condensation type silicone rubber composition, characterized in that the silicone rubber composition is composed of three components A, B and C;

[0050] Component A includes by weight: 107 silicone rubber (viscosity 50000cps) 80, heavy calcium carbonate 110, methyl silicone oil (viscosity 50cps) 40, hydroxyl silicone oil (viscosity 150cps) 5, carbon black 1;

[0051] Component B includes by weight: ethyl orthosilicate 2, γ-aminopropyltriethoxysilane 1, methyl silicone oil (viscosity 50cps) 20, dibutyltin dilaurate 0.05;

[0052] Component C includes by weight: 0.5 linseed oil.

Embodiment 2

[0054] A matte condensation type silicone rubber composition, characterized in that the silicone rubber composition is composed of three components A, B and C;

[0055] Component A includes by weight: 107 silicone rubber 120 (viscosity 1500cps), light calcium carbonate 20, methyl silicone oil (viscosity 500cps) 80, hydroxyl silicone oil (viscosity 5cps) 10, carbon black 5;

[0056] Component B includes by weight: 15 propyl orthosilicate, 8 gamma-(methacryloyloxy)propyltrimethoxysilane, 35 methyl silicone oil (viscosity 500 cps), 0.6 dioctyltin dilaurate;

[0057] Component C includes: tung oil 5 in parts by weight.

Embodiment 3

[0059] A matte condensation type silicone rubber composition, characterized in that the silicone rubber composition is composed of three components A, B and C;

[0060] Component A includes by weight: 107 silicone rubber 100 (viscosity 25000cps), talcum powder 60, methyl silicone oil (viscosity 250cps) 5, hydroxyl silicone oil (viscosity 250cps) 1, carbon black 10;

[0061] Component B includes by weight parts: methyl trimethoxysilane 10, N-β-aminoethyl-γ-aminopropyl trimethoxysilane 5, methyl silicone oil (viscosity 250cps) 5, dilauric acid di Butyl tin and dioctyl tin dilaurate 0.3;

[0062] Component C includes: castor oil 2.5 parts by weight.

[0063] The preparation method of the silicone rubber composition described in embodiment 1-3 is:

[0064] Separate the three components A, B and C, mix them at room temperature to form a soft silicone elastomer through condensation and crosslinking, in which the matting agent is hydrolyzed under the action of moisture in the air t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com