Transparent dealcoholized single-component RTV silicone rubber sealant and preparation method thereof

A sealant and silicone rubber technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of slow curing speed and no anti-yellowing performance, and achieve fast curing speed and excellent anti-yellowing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

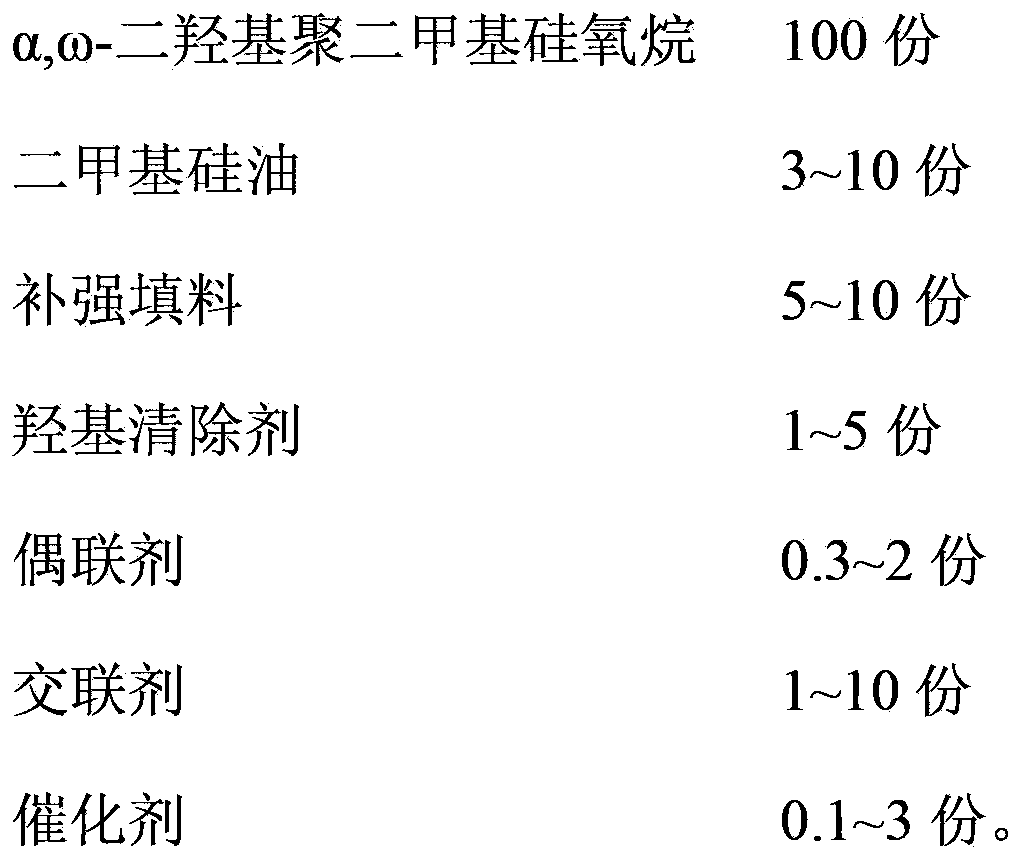

[0037] A transparent dealcoholized one-component RTV silicone rubber sealant, the RTV silicone rubber sealant comprises the following raw materials in parts by mass:

[0038]

[0039] The α, ω-dihydroxy polydimethylsiloxane is α, ω-dihydroxy polydimethylsiloxane with a dynamic viscosity of 1500cps, and the dimethyl silicone oil is dimethyl silicone oil with a dynamic viscosity of 50cps Silicone oil, the reinforcing filler is hydrophilic fumed silica, the hydroxyl scavenger is hexamethyldisilazane, the coupling agent is γ-aminopropyltriethoxysilane, and the cross-linked The coupling agent is ethyl orthosilicate, and the catalyst is diethylaminomethyltriethoxysilane.

[0040] The preparation method of the above-mentioned transparent dealcoholized one-component RTV silicone rubber sealant is as follows:

[0041] (1) Vacuum stir the α,ω-dihydroxy polydimethylsiloxane, simethicone oil, reinforcing filler and hydroxyl scavenger in the power mixer;

[0042] (2) Add the coupling ...

Embodiment 2

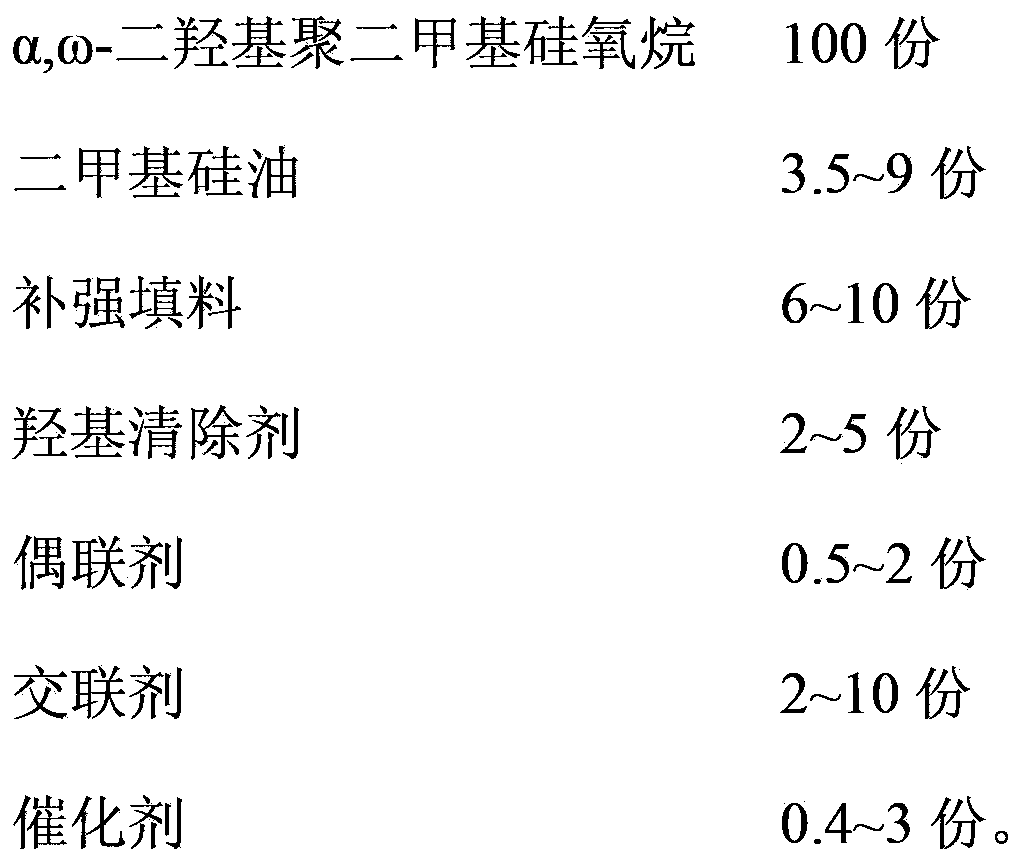

[0045] A transparent dealcoholized one-component RTV silicone rubber sealant, the RTV silicone rubber sealant comprises the following raw materials in parts by mass:

[0046]

[0047] The α, ω-dihydroxy polydimethylsiloxane is α, ω-dihydroxy polydimethylsiloxane with a dynamic viscosity of 50000cps, and the dimethyl silicone oil is dimethyl silicone oil with a dynamic viscosity of 500cps Silicone oil, the reinforcing filler is precipitated silica, the hydroxyl scavenger is hexamethyldisilazane, and the coupling agent is γ-aminopropyltriethoxysilane and γ-(2,3 - a mixture of glycidoxy)propyltrimethoxysilane, the crosslinking agent being a mixture of n-methyltrimethoxysilane and vinyltriethoxysilane, the catalyst being anilinomethyltriethoxy silane.

[0048] The preparation method of above-mentioned transparent dealcoholization type one-component RTV silicone rubber sealant comprises the steps:

[0049] (1) Vacuum stir the α,ω-dihydroxy polydimethylsiloxane, simethicone oil...

Embodiment 3

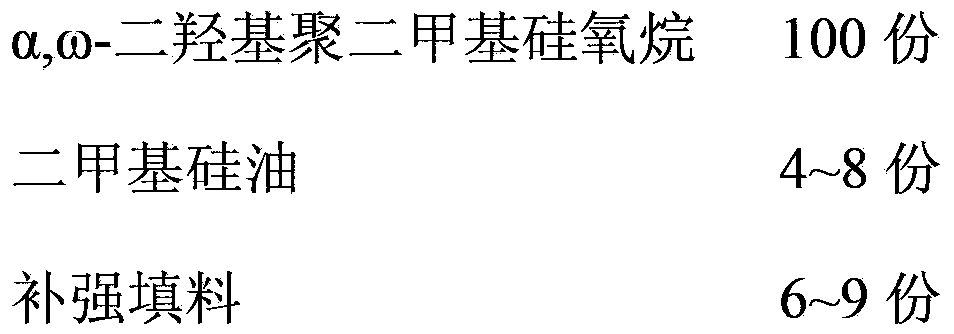

[0053] A transparent dealcoholized one-component RTV silicone rubber sealant, the RTV silicone rubber sealant comprises the following raw materials in parts by mass:

[0054]

[0055] The α, ω-dihydroxy polydimethylsiloxane is α, ω-dihydroxy polydimethylsiloxane with a dynamic viscosity of 26000cps, and the dimethyl silicone oil is dimethyl silicone oil with a dynamic viscosity of 340cps Silicone oil, the reinforcing filler is hydrophilic fumed silica and precipitated silica, the hydroxyl scavenger is hexamethyldisilazane, and the coupling agent is γ-aminopropyltriethoxy A mixture of silane and γ-(2,3-glycidoxy)propyltrimethoxysilane, the crosslinking agent being a mixture of ethyl orthosilicate, methyl orthosilicate and vinyltrimethoxysilane, The catalysts are diethylaminomethyltriethoxysilane and anilinomethyltriethoxysilane.

[0056] The preparation method of above-mentioned transparent dealcoholization type one-component RTV silicone rubber sealant, described method co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com