Tackifier, dealcoholized RTV silicone rubber and preparation method thereof

A tackifier, dealcohol-type technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as unsatisfactory bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

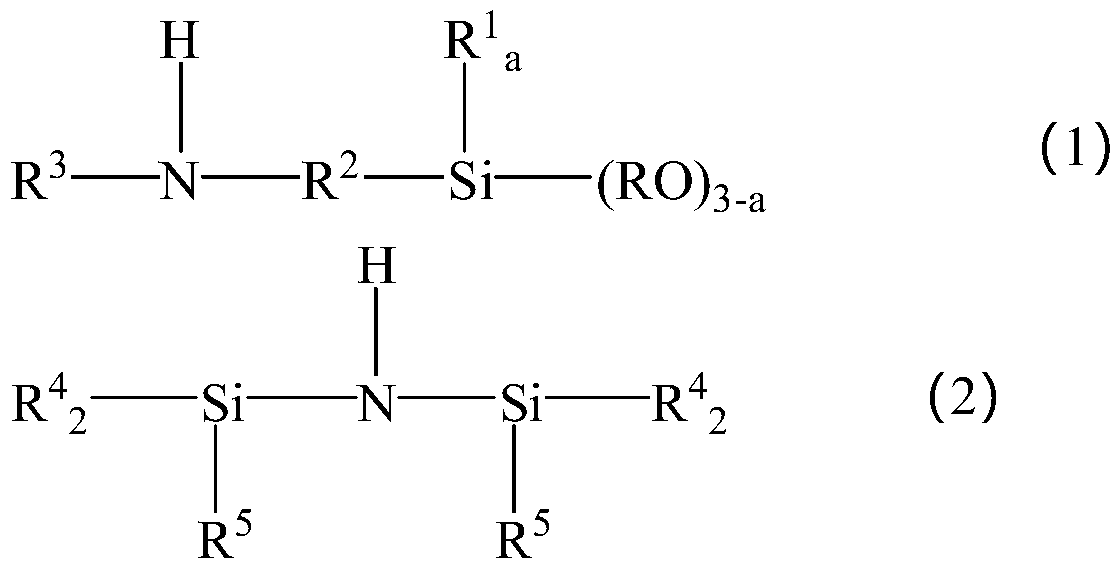

[0112] The present embodiment provides a kind of dealcoholization type RTV silicone rubber tackifier, and its preparation method comprises the steps:

[0113] Put γ-aminopropyltrimethoxysilane and tetramethyldivinyldisilazane with a molar ratio of 1:1 into a reactor with heating, stirring and nitrogen protection, raise the temperature to 90°C, and under nitrogen protection , the reaction was continued for 10 h at a stirring speed of 60 rpm, and the reaction mixture was the tackifier, cooled, discharged, sealed and stored for later use.

Embodiment 2

[0115] This embodiment provides a one-component dealcoholized RTV silicone rubber sealant, the preparation method of which comprises the following steps:

[0116] Add 100 parts of alkoxy-terminated polydimethylsiloxane with a viscosity of 20,000 mPa·s at 25°C and 120 parts of nano-calcium carbonate into the planetary machine, heat to 100°C, and evacuate (vacuum degree is 0.09MPa ) dehydration, mixing evenly, after cooling, add 5 parts of methyltrimethoxysilane, 0.3 part of dioctyltin dilaurate under moisture-proof condition, vacuum (vacuum tightness is 0.09MPa) mix homogeneously; Then add 4.5 parts of embodiment 1 Prepared tackifier, vacuum (vacuum degree: 0.09MPa) mixed evenly, prepared into dealcoholized RTV silicone rubber sealant, denoted as sealant 1.

Embodiment 3

[0118] This embodiment provides a two-component dealcoholized RTV silicone rubber potting compound, the preparation method of which includes the following steps:

[0119] Preparation of component A: Add 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 1500mPa·s at 25°C, 30 parts of silicon micropowder, and 1.3 parts of carbon black into the planetary machine, heat to 100°C, Vacuumize (vacuum degree is 0.09MPa) to dehydrate, make it evenly mixed, after cooling, seal it for use;

[0120] Preparation of component B: 100 parts of methyl-terminated polydimethylsiloxane with a viscosity of 50 mPa·s at 25°C, 32 parts of tetraethyl orthosilicate, and 20 parts of the tackifier prepared in Example 1 , 0.4 parts of dibutyltin dilaurate are put into the mixer, under the protection of nitrogen, mix evenly, and seal for use;

[0121] Preparation of dealcoholized RTV silicone rubber potting compound: Take 100 parts of component A and 10 parts of component B and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com