Preparation method of methyl ketone oxime methoxy silane

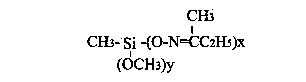

A technology of methylketoximomethoxysilane and methyltrichlorosilane, which is applied in the field of silane crosslinking agent synthesis, can solve the problem that the technical inspiration of methylketoximomethoxysilane is not given and the conversion rate is not high , high color of the product and other problems, to achieve the effect of good cost advantage, good cohesiveness and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

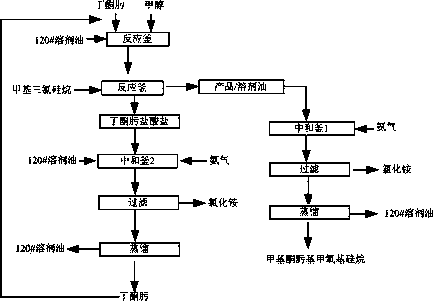

[0024] A kind of preparation method of methyl ketoximino methoxy silane, technological process is as figure 1 Shown, preparation method step is as follows:

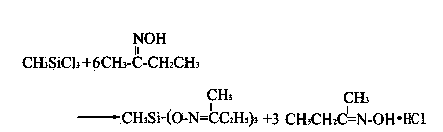

[0025] (1) Add butanone oxime, methanol and No. 120 solvent oil into a stirred reactor, then drop methyltrichlorosilane into the reactor, adjust the drop rate of methyltrichlorosilane, and control the reaction temperature at 30-60°C; the molar ratio of methyltrichlorosilane: butanone oxime: methanol is 1: (5-5.5): 1, and the amount of No. 120 solvent oil is 1-2 times the weight of methyltrichlorosilane.

[0026] (2) After the dropwise addition, let it stand for stratification, and the upper product enters the first neutralization tank, and passes through ammonia gas for neutralization (the temperature of the first neutralization tank is controlled at 70-80°C during the period), and after the pH is greater than 7 Stop, then filter, after ammonium chloride is separated, the semi-finished product of methyl ketoxime methoxys...

Embodiment 1

[0030] In a 3000L reactor with stirring and circulating water cooling, put 1168kg of butanone oxime, 85.6kg of methanol, and 400kg of 120# solvent oil into it. While stirring, add 400kg of methyltrichlorosilane dropwise, adjust the rate of addition, and control The reaction temperature was 30°C. After the dropwise addition was completed, the temperature was kept at 30°C and the reaction was continued for 2 hours. Then let it sit and layer. The upper layer is a mixture of product and solvent oil, which enters the first neutralization tank, and then enters ammonia gas for neutralization. The neutralization temperature is 70°C. Stop when the pH is greater than 7, and then filter. After separating ammonium chloride, it enters the first membrane The evaporator distills off the solvent under the conditions of 100°C and vacuum degree of -0.098Mpa to obtain the methylketoximomethoxysilane product. The lower layer is butanone oxime hydrochloride, enter the second neutralization tank, ...

Embodiment 2

[0033] In a 3000L reactor with stirring and circulating water cooling, put 1238kg of butanone oxime, 85.6kg of methanol, and 400kg of 120# solvent oil into it. While stirring, add 400kg of methyltrichlorosilane dropwise to adjust the rate of addition. The reaction temperature was 40°C. After the dropwise addition was completed, the temperature was kept at 40°C and the reaction was continued for 2 hours. Then let it sit and layer. The upper layer is a mixture of product and solvent oil, which enters the first neutralization tank, and then enters ammonia gas for neutralization. The neutralization temperature is 75°C. Stop when the pH is greater than 7, and then filter. After ammonium chloride is separated, it enters the first membrane. Evaporator, under the conditions of 110°C and vacuum degree of -0.098Mpa, the solvent is distilled off to obtain the methyl ketoximomethoxysilane product. The lower layer is butanone oxime hydrochloride, enter the second neutralization tank, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com