Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

A dealcoholized, silicone rubber technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems that the physical properties and storage stability of silicone rubber cannot meet the existing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

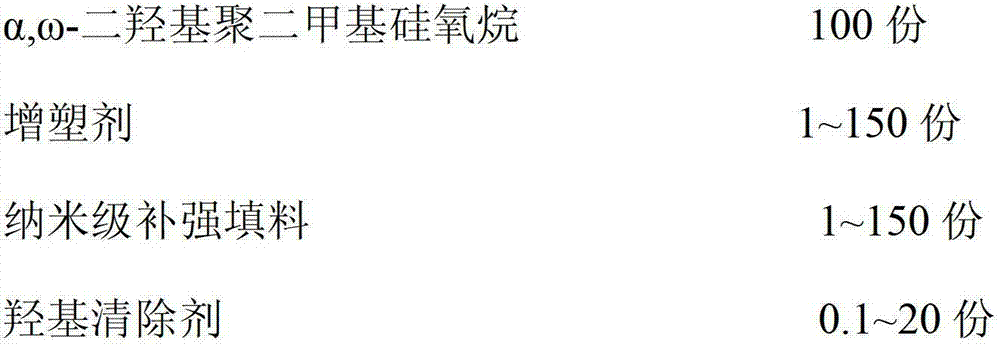

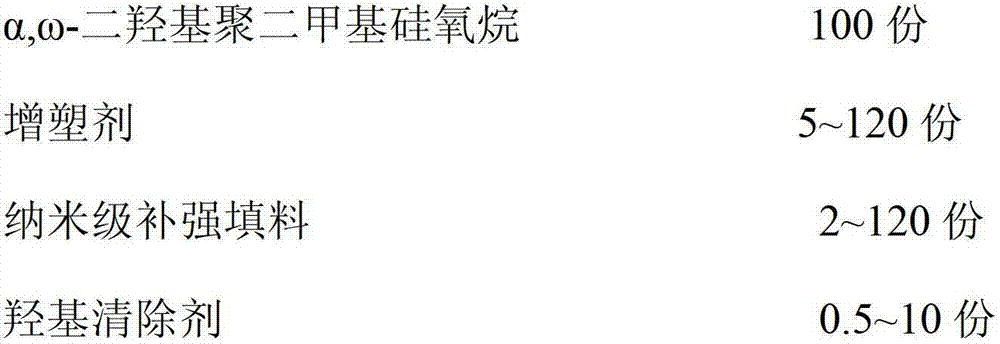

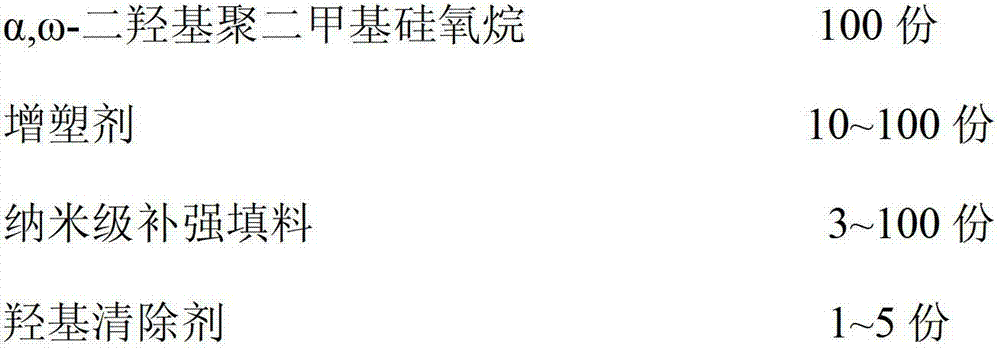

Method used

Image

Examples

Embodiment 1

[0065] (1) Preparation of the base material, 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 50000cps, 10 parts of dimethyl silicone oil with a viscosity of 5000cps, 100 parts of hydrophilic fumed silica, six methyl 1 part of base disilazane was dehydrated and blended in a power mixer at a temperature of 140°C and a vacuum degree of -0.09MPa for 180min, and cooled to room temperature with isolated air to obtain a base material;

[0066] (2) Take 100 parts of the base material and add it to the power mixer, evacuate to -0.09MPa, stir for 10 minutes, add 15 parts of chloromethyltriethoxysilane, evacuate to -0.1MPa, and stir for 30 minutes;

[0067] (3) Add 2 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane, vacuumize to -0.1MPa, and stir for 30 minutes to obtain the finished product.

Embodiment 2

[0069] (1) Preparation of the base material, 100 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 1000cps, 1 part of diethyl silicone oil with a viscosity of 10cps, 2 parts of precipitated white carbon black, hexamethyldisiloxane Dehydrate and blend 0.1 part of azane in a dynamic mixer at a temperature of 80°C and a vacuum of -0.01MPa for 30 minutes, and cool to room temperature with isolated air to obtain a base material;

[0070] (2) Take 100 parts of base glue and add it to a power mixer, vacuumize to -0.01MPa, add 0.1 part of dichloromethyltriethoxysilane, vacuumize to -0.01MPa, and stir for 10 minutes;

[0071] (3) Add 0.1 part of N-aminoethyl-γ-aminopropyltrimethoxysilane, vacuumize to -0.01MPa, and stir for 3 minutes to obtain the finished product.

Embodiment 3

[0073] (1) Preparation of the base material, 100 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 80000cps, 150 parts of diethyl silicone oil with a viscosity of 9000cps, 100 parts of precipitated white carbon black, and 50 parts of nano-alumina , 10 parts of magnesium oxide, 10 parts of hexamethyldisilazane, dehydration and blending in a power mixer at a temperature of 200 ° C and a vacuum degree of -0.3 MPa for 280 min, and cooling to room temperature with isolated air to obtain a base material;

[0074] (2) Take 100 parts of the base glue and add it to the power mixer, evacuate to -0.3MPa, stir for 80 minutes, add 10 parts of chloromethyldiethylaminodiethoxysilane, dichloromethyltriethoxy 20 parts of silane, vacuum to -0.3MPa, stir for 5min;

[0075] (3) Add 2 parts of vinyltriethoxysilane, 2 parts of N-methyl-γ-aminopropyltrimethoxysilane, 4 parts of divinyltriaminopropyltrimethoxysilane, and vacuum to -0.3 MPa, stirred for 50min to obtain the finished prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com