All-plastic water-ripple self-setting runway and preparation method thereof

A technology of water ripple and water condensation, applied in the direction of roads, roads, coatings, etc., can solve the problems of difficult to master the ratio and affect the flatness of the plastic track, achieve good cross-linking effect, promote curing rate, improve wear resistance and wear resistance. The effect of tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

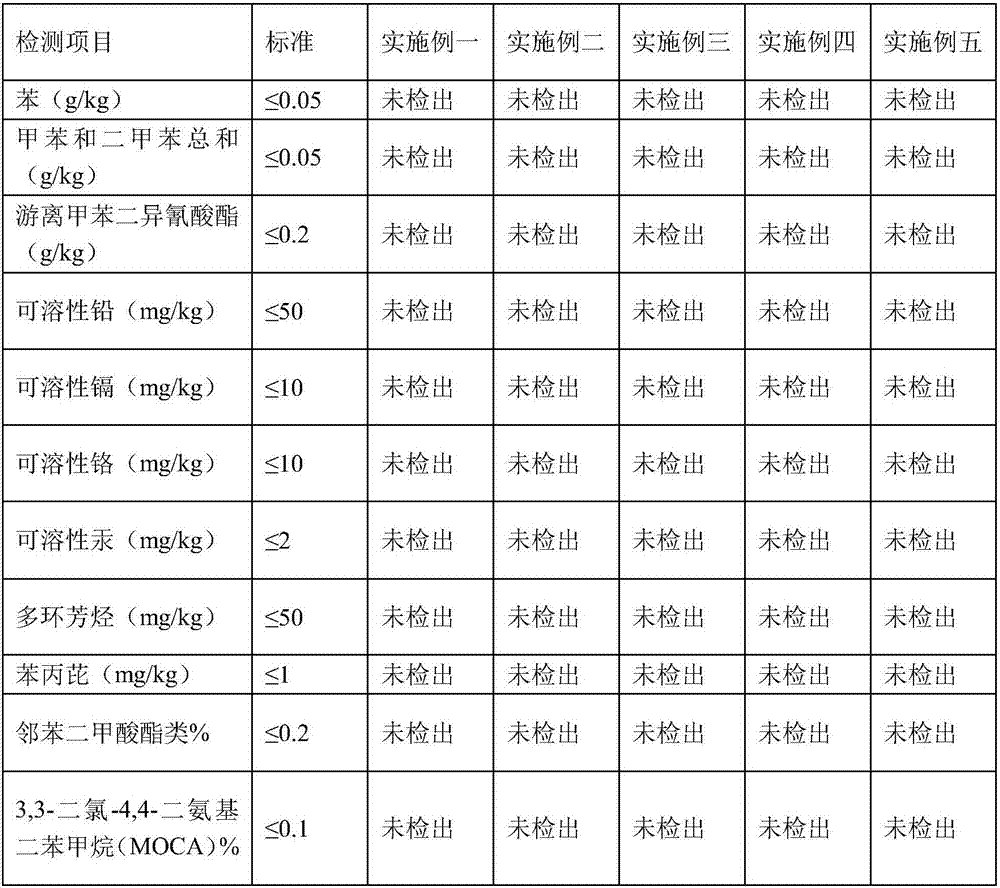

[0050] Embodiment 1: An all-plastic self-consolidating corrugated runway is prepared by the following steps:

[0051] (1) After the underlying base layer is cleaned and leveled, a layer of primer is uniformly coated on top of it; in this embodiment, the base layer is a concrete foundation, and the base coat is a special back sealer for concrete.

[0052] (2) Take 1000kg of component A and 7000kg of component B, pour component B into component A and stir thoroughly at 26°C for 3 minutes, add 32kg of catalyst and stir for 2 minutes until component A, component B and catalyst are stirred evenly to form a primer The mixture, the primer mixture is paved on the primer layer to form a flexible elastic layer; Component A includes polyether polyol-1000d 470kg, polyether polyol-200d 130kg, MDI isocyanate 450kg, palm oil 300kg; component B Including polyether polyol-2000d 200kg, polyether polyol-1000d 400kg, antioxidant 1010 14kg, iron oxide red 50kg, talcum powder 400 mesh 1400kg, ultra...

Embodiment 2

[0055] Embodiment 2: An all-plastic self-consolidating corrugated runway is made by the following steps:

[0056] (1) After the underlying base layer is cleaned and leveled, a layer of primer is uniformly coated on top of it; in this embodiment, the base layer is a concrete foundation, and the base coat is a special back sealer for concrete.

[0057] (2) Take 1000kg of component A and 5300kg of component B, pour component B into component A and stir at 10°C for 5 minutes, add 18.9kg of catalyst and stir for 3 minutes until component A, component B and catalyst are uniformly formed Primer mixture, the primer mixture spreads on the primer layer to form a flexible elastic layer; wherein component A includes polyether polyol-1000d 460kg, polyether polyol-200d 120kg, MDI isocyanate 430kg, palm oil 280kg; Part B includes polyether polyol-2000d 160kg, polyether polyol-1000d 390kg, antioxidant 168 12kg, iron oxide red 46kg, talcum powder 400 mesh 1350kg, ultraviolet absorber 12kg, pal...

Embodiment 3

[0060] Embodiment 3: An all-plastic self-consolidating corrugated runway is made by the following steps:

[0061] (1) After the underlying base layer is cleaned and leveled, a layer of primer is uniformly coated on top of it; in this embodiment, the base layer is a concrete foundation, and the base coat is a special back sealer for concrete.

[0062] (2) Take 1000kg of component A and 7200kg of component B, pour component B into component A and stir at 35°C for 5 minutes, add 41kg of catalyst and stir for 3 minutes until component A, component B and catalyst are uniformly formed Primer mixture, the primer mixture spreads on the primer layer to form a flexible elastic layer; Component A includes polyether polyol-1000d 500kg, polyether polyol-200d 150kg, MDI isocyanate 460kg, palm oil 350kg; Part B includes polyether polyol-2000d 200kg, polyether polyol-1000d 420kg, antioxidant B900 18kg, iron oxide red 53kg, talcum powder 400 mesh 1470kg, ultraviolet absorber 19kg, palm oil 680...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com