Pavement abrasion-resistant layer based on epoxy resin and method for preparing same

A technology of epoxy resin and wear-resistant layer, which is applied in the direction of epoxy resin glue, cohesive pavement paved on site, roads, etc., and can solve the problem of poor compatibility between epoxy resin and asphalt resin, uneven cured product, and aging resistance Poor performance and other problems, achieve good low-temperature deformation ability, reduce repair and maintenance costs, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

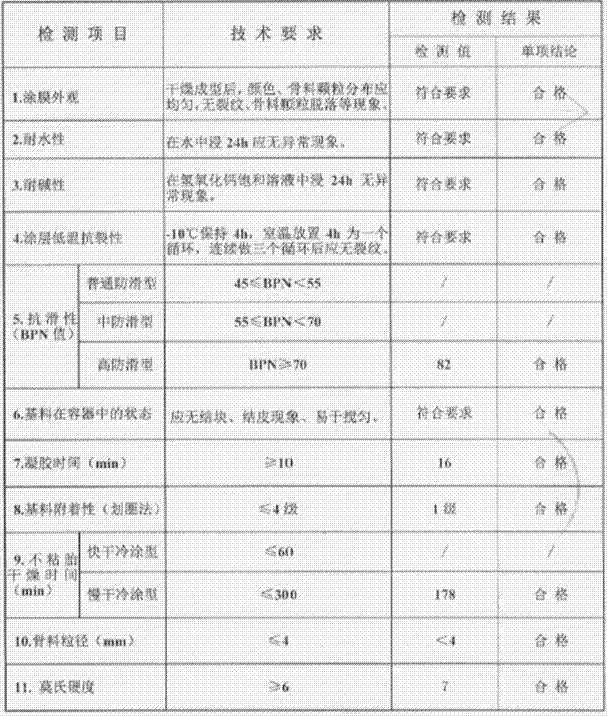

Image

Examples

Embodiment 1

[0066] A pavement wear-resistant layer based on epoxy resin, which is made of the following raw materials in parts by weight:

[0067] Raw material parts by weight

[0068] 65 parts of epoxy resin

[0069] Modified epoxy resin 11 parts

[0070] Dioctyl phthalate 4 parts

[0071] Amino-terminated polyether (ATPE for short) 15 parts

[0072] Alicyclic amine curing agent 30 parts

[0073] Modified amine curing agent 12 parts

[0074] 44 parts of curing accelerator.

[0075] Step 1), weigh epoxy resin, modified epoxy resin, and dioctyl phthalate in proportion and mix them in a stirring container, which is component A;

[0076] Step 2), weigh the amino-terminated polyether, alicyclic amine curing agent, modified amine curing agent, and curing accelerator in proportion, put them in a stirring container and mix them evenly, and become component B;

[0077] Step 3) Pour component B into the pre-prepared container for stirring, and then add component A in a ratio of 1:1 by weigh...

Embodiment 2

[0082] Example 2: A pavement wear-resistant layer based on epoxy resin, which is made of the following raw materials in parts by weight (preferred range):

[0083] Raw material parts by weight

[0084] 70 parts of epoxy resin

[0085] Modified epoxy resin 22 parts

[0086] Dioctyl phthalate 9 parts

[0087] Amino-terminated polyether (ATPE for short) 17 parts

[0088] Alicyclic amine curing agent 19 parts

[0089] Modified amine curing agent 16 parts

[0090] 44 parts of curing accelerator.

[0091] Step 1), weigh epoxy resin, modified epoxy resin, and dioctyl phthalate in proportion and mix them in a stirring container, which is component A;

[0092] Step 2), weigh the amino-terminated polyether, alicyclic amine curing agent, modified amine curing agent, and curing accelerator in proportion, put them in a stirring container and mix them evenly, and become component B;

[0093] Step 3) Pour component B into the pre-prepared container for stirring, and then add compone...

Embodiment 3

[0098] Example 3: A pavement wear-resistant layer based on epoxy resin, which is made of the following raw materials in parts by weight (preferable range):

[0099] Raw material parts by weight

[0100] 80 parts of epoxy resin

[0101] Modified epoxy resin 27 parts

[0102] Dioctyl phthalate 12 parts

[0103] Amino-terminated polyether (ATPE for short) 23 parts

[0104] Alicyclic amine curing agent 28 parts

[0105] Modified amine curing agent 25 parts

[0106] 30 parts of curing accelerator.

[0107] Step 1), weigh epoxy resin, modified epoxy resin, and dioctyl phthalate in proportion and mix them in a stirring container, which is component A;

[0108] Step 2), weigh the amino-terminated polyether, alicyclic amine curing agent, modified amine curing agent, and curing accelerator in proportion, put them in a stirring container and mix them evenly, and become component B;

[0109] Step 3) Pour component B into the pre-prepared container for stirring, and then add compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com