Laser paper printing ink and preparation method thereof

A technology of laser paper and ink, which is applied in the field of packaging, can solve the problems of less research on the performance of the ink itself, and achieve the effects of being conducive to drying, solving poor compatibility, and improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

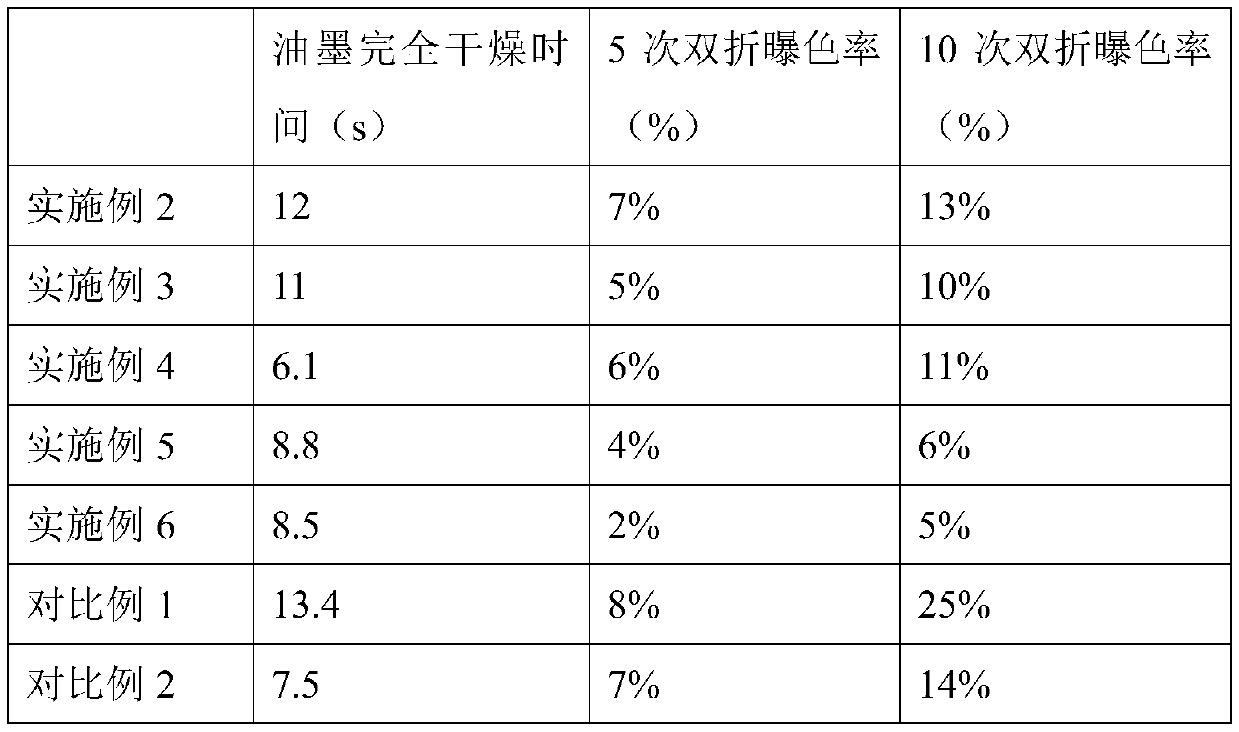

Examples

Embodiment 1

[0028] A laser paper ink, said laser paper ink comprises the following components by weight: 15-20 parts of water-based acrylic resin, 10-20 parts of water-based polyurethane resin, 10-18 parts of dipropylene glycol diacrylate, 15-20 parts of pigment 20 parts, 6-10 parts of nano-titanium dioxide, 2-4 parts of nano-zinc oxide, 8-10 parts of filler, 14-20 parts of reactive diluent, 3-5 parts of photoinitiator, 1-3 parts of photosensitizer, 0.1 parts of auxiliary agent -0.2 parts.

[0029] Preferably, the photoinitiator is a-hydroxycyclohexylbenzophenone or a-hydroxyisopropylbenzophenone;

[0030] The photosensitizer is triethanolamine or N-methyldiethanolamine;

[0031] Described reactive diluent is ethanol;

[0032] The auxiliary agent is composed of organosilicon defoamer and diacetone alcohol in a mass ratio of 1:(0.3-0.8).

[0033] Preferably, the filler is composed of talcum powder and calcium carbonate according to a mass ratio of 1:(0.5-0.8), and the particle size of t...

Embodiment 2

[0045]A laser paper ink, said laser paper ink comprises the following components in parts by weight: 18 parts of water-based acrylic resin, 15 parts of water-based polyurethane resin, 15 parts of dipropylene glycol diacrylate, 17 parts of pigment, 8 parts of nano-titanium dioxide, 3 parts of nano zinc oxide, 8.5 parts of filler, 16 parts of reactive diluent, 4 parts of photoinitiator, 2 parts of photosensitizer, and 0.15 part of auxiliary agent.

[0046] Preferably, the photoinitiator is a-hydroxycyclohexylbenzophenone or a-hydroxyisopropylbenzophenone;

[0047] The photosensitizer is triethanolamine or N-methyldiethanolamine;

[0048] Described reactive diluent is ethanol;

[0049] The auxiliary agent is composed of silicone defoamer and diacetone alcohol in a mass ratio of 1:0.5.

[0050] Preferably, the filler is composed of talcum powder and calcium carbonate in a mass ratio of 1:0.6, and the particle size of the filler is 200-300 mesh.

Embodiment 3

[0052] Others are the same as in Example 2, except that the laser paper ink also includes the following components in parts by weight: 0.07 parts of yeast dextran.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com