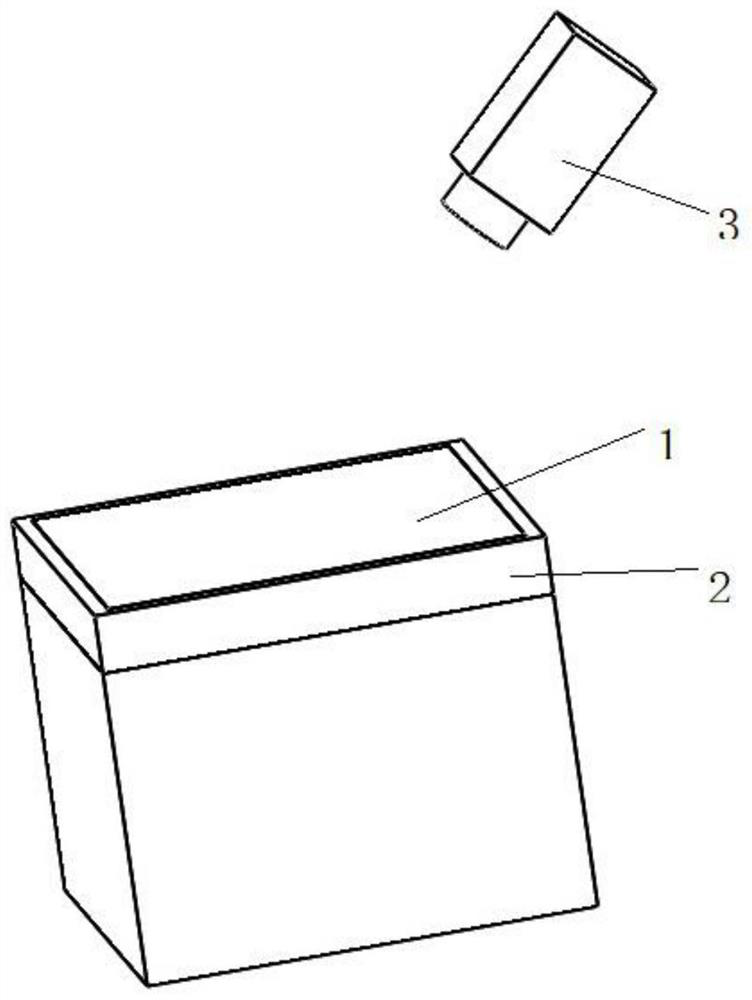

Laser melting forming method and device for pure copper part

A laser melting and control device technology, which is applied in the direction of improving process efficiency, improving energy efficiency, and additive processing, can solve the problems of high difficulty in deformation control and complicated injection molding process, so as to avoid pure copper oxidation and process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The laser melting and forming experiment of copper parts was carried out on pure copper powder. The laser power was 400W, the scanning rate was 800mm / s, the substrate was heated to 200°C, and the layer thickness was 50 microns. Without thermal imaging and ultrasonic vibration closed-loop control, Before forming, the 40-layer forming surface showed obvious metallic luster, and the forming continued, the surface gradually darkened, and the surface unevenness was more obvious. Using an optical microscope to observe the metallographic sample in the furnace, it is found that there are a large number of unfused regions above 5mm in the sample.

Embodiment 2

[0060] The laser melting and forming experiment of copper parts is carried out on pure copper powder. The laser power is 400W, the scanning rate is 800mm / s, the substrate is heated to 200°C, and the layer thickness is 50 microns. Thermal imaging and ultrasonic vibration are used for closed-loop control. Ultrasonic vibration device The vibration frequency is 25KHz, and the output power can be adjusted within the range of 100-500W. The output power of ultrasonic vibration was controlled at 150W, and the energy input of the first 95 layers was found to be moderate through thermal imaging, and then the energy input was weak, and the metallic luster of the surface gradually weakened, but the smoothness of the surface was better than that of Example 1. Observing the internal tissue, it was found that no fusion occurred in the interval range of the sample height of 11-20mm, and the tissue was obviously better than that of Example 1.

Embodiment 3

[0062] The laser melting and forming experiment of copper parts is carried out on pure copper powder. The laser power is 400W, the scanning rate is 800mm / s, the substrate is heated to 200°C, and the layer thickness is 50 microns. Thermal imaging and ultrasonic vibration are used for closed-loop control. Ultrasonic vibration device The vibration frequency is 25KHz, and the output power can be adjusted within the range of 100-500W. Observe the effect of ultrasonic vibration on the defects in the furnace metallographic samples. No ultrasonic vibration is introduced into the first 40 layers, and ultrasonic vibration is introduced from the 40th to 80th layers. Thermal imaging shows that there is no significant difference in energy input compared with the first 40 layers; as the forming continues, the ultrasonic vibration is increased according to the molten pool temperature monitored by thermal imaging. Output power of vibration, homogenization of energy input area in the process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com