Water-based ink with antibacterial properties and preparation method thereof

A water-based ink and performance technology, applied in inks, household appliances, applications, etc., can solve the problems of poor compatibility between antibacterial materials and ink components, organic antibacterial agents are insoluble in water, affecting ink performance, etc., and achieve good adhesion performance. and antibacterial properties, enhance the ability to dissolve resin, increase the effect of affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

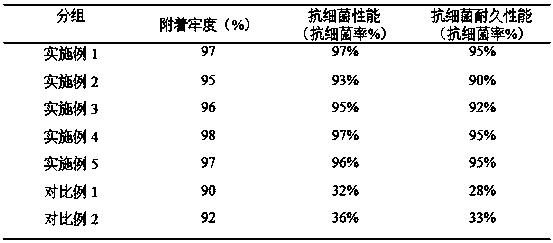

Examples

Embodiment 1

[0024] A water-based antibacterial ink comprises the following components by weight:

[0025] 23 parts of water-based acrylic resin (including 6 parts of Arolon resin and 17 parts of acrylic emulsion);

[0026] 10 parts of pigment (including 3 parts of carbon black, 3 parts of benzidine yellow PY12, 2 parts of permanent red-F, 2 parts of phthalocyanine blue BGS);

[0027] 15 parts of filler (including 4 parts of titanium dioxide, 7 parts of nano-calcium carbonate, 4 parts of superfine calcined kaolin);

[0028] 5 parts of additives (including 3 parts of water-based wax slurry, 1 part of water-based wear-resistant wax, 0.5 parts of micronized wax, 0.3 parts of wax emulsion, and 0.2 parts of water-based defoamer);

[0029] 5 parts of antibacterial agent (that is, 5 parts of tea saponin);

[0030] 42 parts of solvent (including 4 parts of absolute ethanol, 1.5 parts of propylene glycol, 1 part of 25 wt% ammonia water, 0.5 parts of monoethanolamine, and 35 parts of deionized wat...

Embodiment 2

[0033] A water-based antibacterial ink comprises the following components by weight:

[0034] 27 parts of water-based acrylic resin (including 8 parts of Arolon resin and 19 parts of acrylic emulsion);

[0035] 6 parts of pigment (including 2 parts of carbon black, 2 parts of benzidine yellow PY12, 1 part of permanent red-F, 1 part of phthalocyanine blue BGS);

[0036] 20 parts of filler (including 6 parts of titanium dioxide, 9 parts of nano-calcium carbonate, 5 parts of superfine calcined kaolin);

[0037] 3 parts of additives (including 1.5 parts of water-based wax slurry, 0.5 parts of water-based wear-resistant wax, 0.3 parts of micronized wax, 0.4 parts of wax emulsion, and 0.3 parts of water-based defoamer);

[0038] 3 parts of antibacterial agent (that is, 3 parts of tea saponin);

[0039] 41 parts of solvent (including 6 parts of absolute ethanol, 0.5 parts of propylene glycol, 3 parts of 25 wt% ammonia water, 1.5 parts of monoethanolamine, and 30 parts of deionized ...

Embodiment 3

[0042] A water-based antibacterial ink comprises the following components by weight:

[0043] 25 parts of water-based acrylic resin (including 7 parts of Arolon resin and 18 parts of acrylic emulsion);

[0044] 8 parts of pigments (including 2.5 parts of carbon black, 2.5 parts of benzidine yellow PY12, 1.5 parts of permanent red-F, 1.5 parts of phthalocyanine blue BGS);

[0045] 17 parts of filler (including 6 parts of titanium dioxide, 8 parts of nano-calcium carbonate, 3 parts of superfine calcined kaolin);

[0046]4 parts of additives (including 2 parts of water-based wax slurry, 1 part of water-based wear-resistant wax, 0.4 parts of micronized wax, 0.4 parts of wax emulsion, and 0.2 parts of water-based defoamer);

[0047] 4 parts of antibacterial agent (that is, 4 parts of tea saponin);

[0048] 42 parts of solvent (including 5 parts of absolute ethanol, 1 part of propylene glycol, 2 parts of 25wt% ammonia water, 1 part of monoethanolamine, and 33 parts of deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com