Method for preparing porous Co3O4 powder

A technology of powder and cobalt nitrate, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve problems such as shortage, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1.22 g of Co(NO 3 ) 2 ?6H 2 O and 1.75 g of C 2 h 5 NO 2 Completely dissolved in 10 mL of distilled water to obtain a transparent solution, and then the crucible containing the above solution was placed in a muffle furnace and heated at 400 °C. After the solution experienced boiling, bubbling, and decomposition, a black foam-like substance was obtained, and the foam was further heat-treated at 355 °C for 1.0 h to obtain porous Co 3 o 4 Powder.

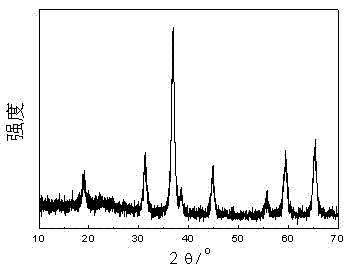

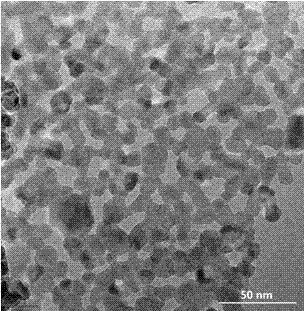

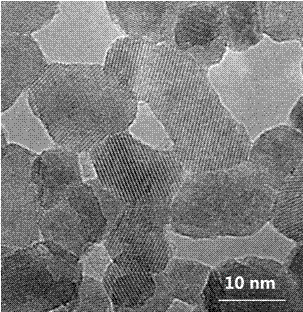

[0022] figure 1 It is the X-ray diffraction pattern of the product, and it can be known by comparison with the standard card that the phase of the obtained product is a single-phase Co 3 o 4 . Using the Scherrer formula, the average grain size of the product can be obtained to be 13 nm. figure 2 with image 3 The transmission electron micrographs and high-resolution transmission electron micrographs of the obtained product are respectively, and it can be seen that the product has a porous structure. The specific su...

Embodiment 2

[0024] 1.22 g of Co(NO 3 ) 2 ?6H 2 O and 1.75 g of C 2 h 5 NO 2 Completely dissolved in 10 mL of distilled water to obtain a transparent solution, and then the crucible containing the above solution was placed in a muffle furnace and heated at 400 °C. After the solution experienced boiling, bubbling, and decomposition, a black foam-like substance was obtained, and the foam was further heat-treated at 450 °C for 1.0 h to obtain porous Co 3 o 4 Powder.

[0025] Figure 4 It is the X-ray diffraction pattern of the product, and it can be known by comparison with the standard card that the phase of the obtained product is a single-phase Co 3 o 4 . Figure 5 As a transmission electron micrograph of the obtained product, it can be seen that the product has a porous structure.

Embodiment 3

[0027] 1.22 g of Co(NO 3 ) 2 ?6H 2 O and 1.75 g of C 2 h 5 NO 2 Completely dissolved in 10 mL of distilled water to obtain a transparent solution, and then the crucible containing the above solution was placed in a muffle furnace and heated at 400 °C. After the solution experienced boiling, foaming, and decomposition, a black foam-like substance was obtained, and the foam was further heat-treated at 550 °C for 1.5 hours to obtain porous Co 3 o 4 Powder.

[0028] Image 6 It is the X-ray diffraction pattern of the product, and it can be known by comparison with the standard card that the phase of the obtained product is a single-phase Co 3 o 4 . Figure 7 with Figure 8 They are field emission scanning electron micrographs and transmission electron micrographs of the obtained product respectively, and it can be seen that the product has a porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com