Preparing method of cobalt nanometer materials

A technology of cobalt nanometer and cobalt nitrate, applied in nanotechnology and other directions, can solve the problems of high production cost, impact on health, complicated preparation process, etc., and achieve the effects of simple production equipment, ensuring uniformity and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

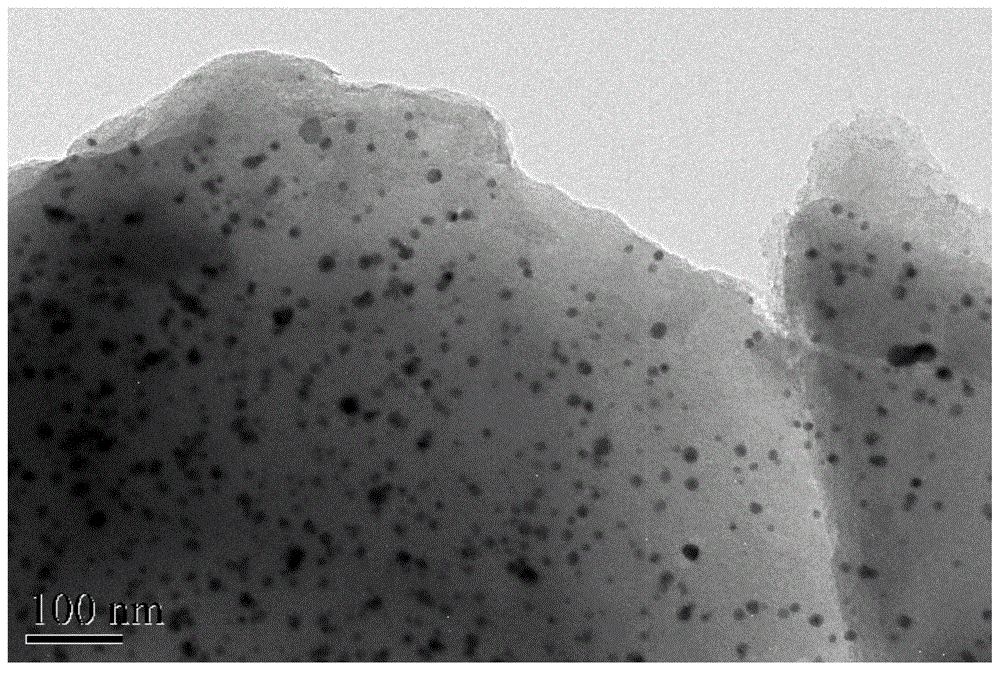

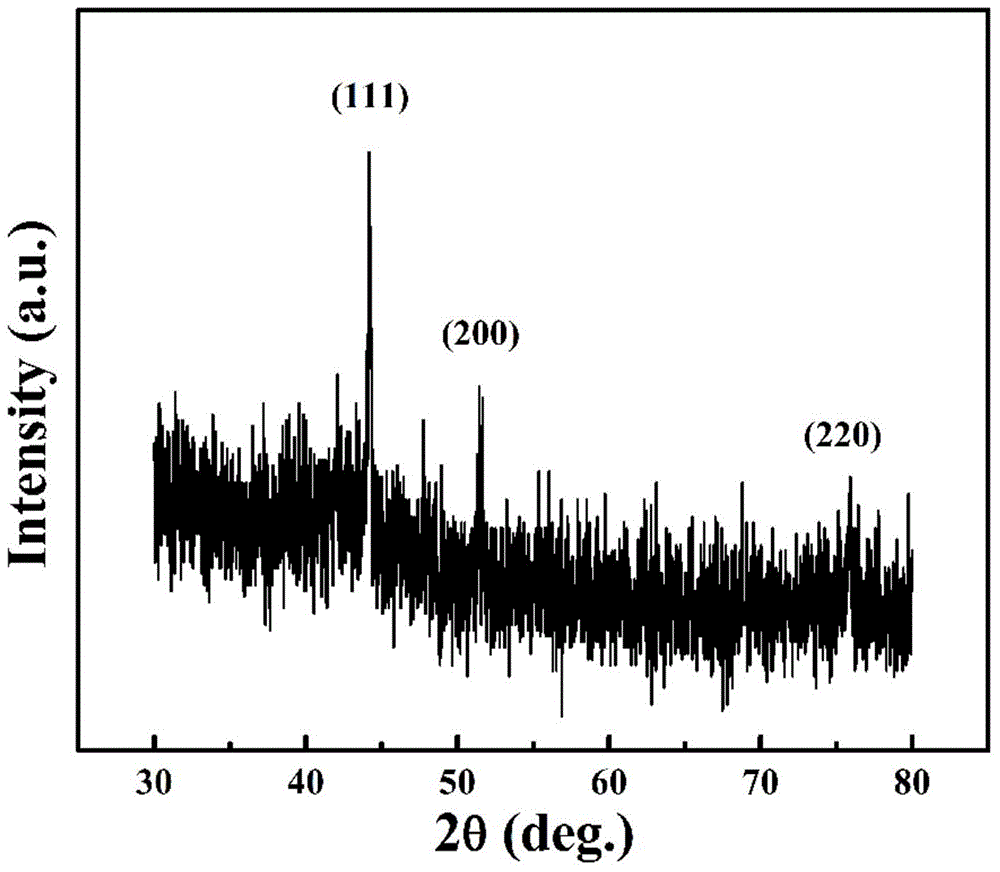

[0026] Example 1: Dissolve 1.4699g of cobalt nitrate hexahydrate in 0.1L of deionized water, then weigh 2.1123g of citric acid and add to the above solution, stir magnetically, and add 2.2200g of dispersant to the solution after the citric acid is completely dissolved PVP, continue to stir until the PVP is completely dissolved, put the mixed solution in a drying oven and dry at 150°C for 15 hours to obtain a loose and porous precursor, and then put the precursor in a muffle furnace for calcination. During the calcination process, the tube furnace The inert atmosphere is continuously passed through for protection, the calcination temperature is 300° C., and the calcination time is 7 hours. figure 1 It is the TEM picture of the sample, and it can be seen from the picture that the particle size of the cobalt nanoparticles is 5-10 nm, and the dispersion is good. figure 2 It is the XRD pattern of the sample, and there are three obvious diffraction peaks in the figure. Analysis by ...

Embodiment 2

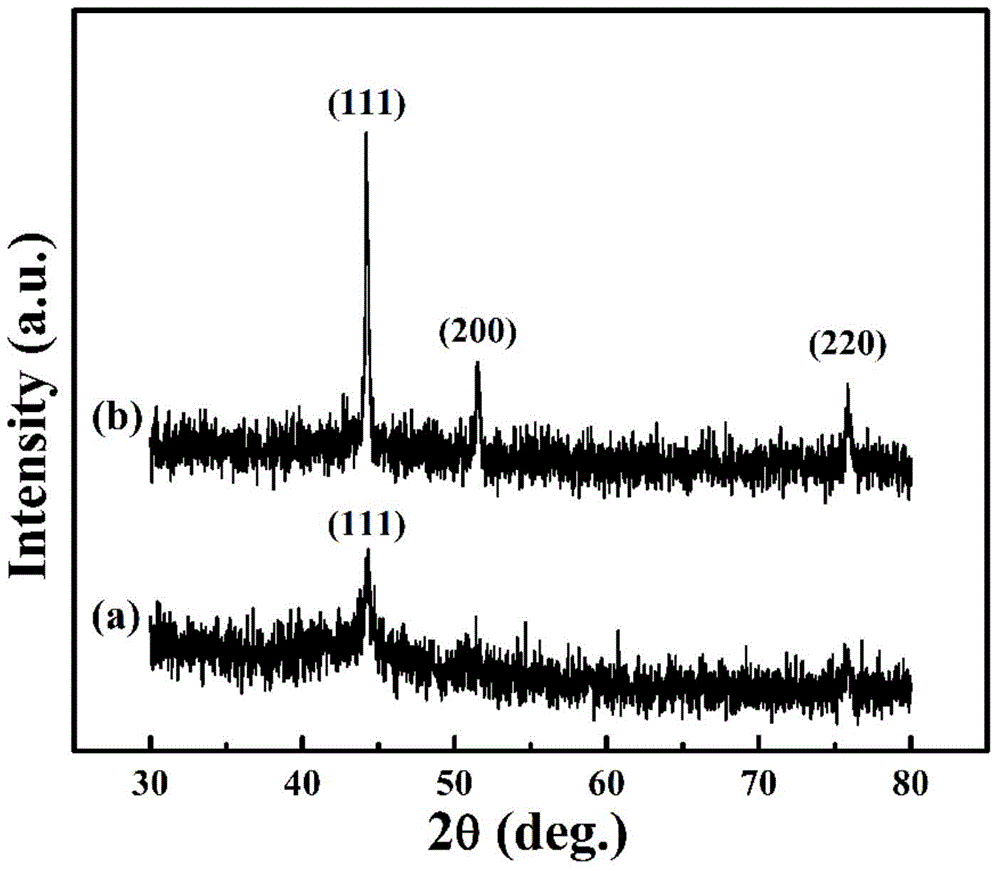

[0027] Example 2: 1.7638g of cobalt nitrate hexahydrate was dissolved in 0.1L of deionized water, then 1.5899g of ascorbic acid was weighed and added to the above solution, stirred magnetically, and 2.6640g of dispersant PVP was added to the solution after the ascorbic acid was completely dissolved. Continue to stir until the PVP is completely dissolved, put the mixed solution in a drying oven and dry at 160°C for 15 hours to obtain a loose and porous precursor, and then put the precursor in a muffle furnace for calcination. During the calcination process, the tube furnace continues to An inert atmosphere was introduced for protection, the calcination temperatures were respectively set at 300° C. and 500° C., and the calcination time was 6 hours. When the calcination temperature is 300°C ( image 3 a), there is only one very sharp diffraction peak on the XRD pattern of the sample, and the analysis shows that the product at this time is face-centered cubic cobalt. However, whe...

Embodiment 3

[0028] Example 3: Dissolve 2.0578g of cobalt nitrate hexahydrate in 0.1L of deionized water, then weigh 2.0559g of ethylenediaminetetraacetic acid and add it to the above solution, stir it magnetically, and add to the solution after the ethylenediaminetetraacetic acid is completely dissolved. Add 2.3310g of dispersant PVP to the mixture, continue stirring until the PVP is completely dissolved, put the mixed solution in a drying oven and dry at 170°C for 10 hours to obtain a loose and porous precursor, and then put the precursor in a muffle furnace for calcination. During the calcination process, an inert atmosphere was continuously passed into the tube furnace for protection, the calcination temperature was 500° C., and the calcination time was 6 hours. Figure 4 It is the XRD pattern of the sample, and there are three obvious diffraction peaks in the figure, and the analysis shows that the product at this time is a face-centered cubic cobalt nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com