Preparation method of cobalt and nitrogen codoped carbon nanoparticle-carbon nanotube composite material

A nanoparticle and carbon nanotube technology, applied in the field of nanocomposite material preparation, can solve the problems of expensive instruments, complicated processes, unfavorable large-scale production, complicated processes, etc., and achieves low cost, aerobic reduction electrocatalytic performance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

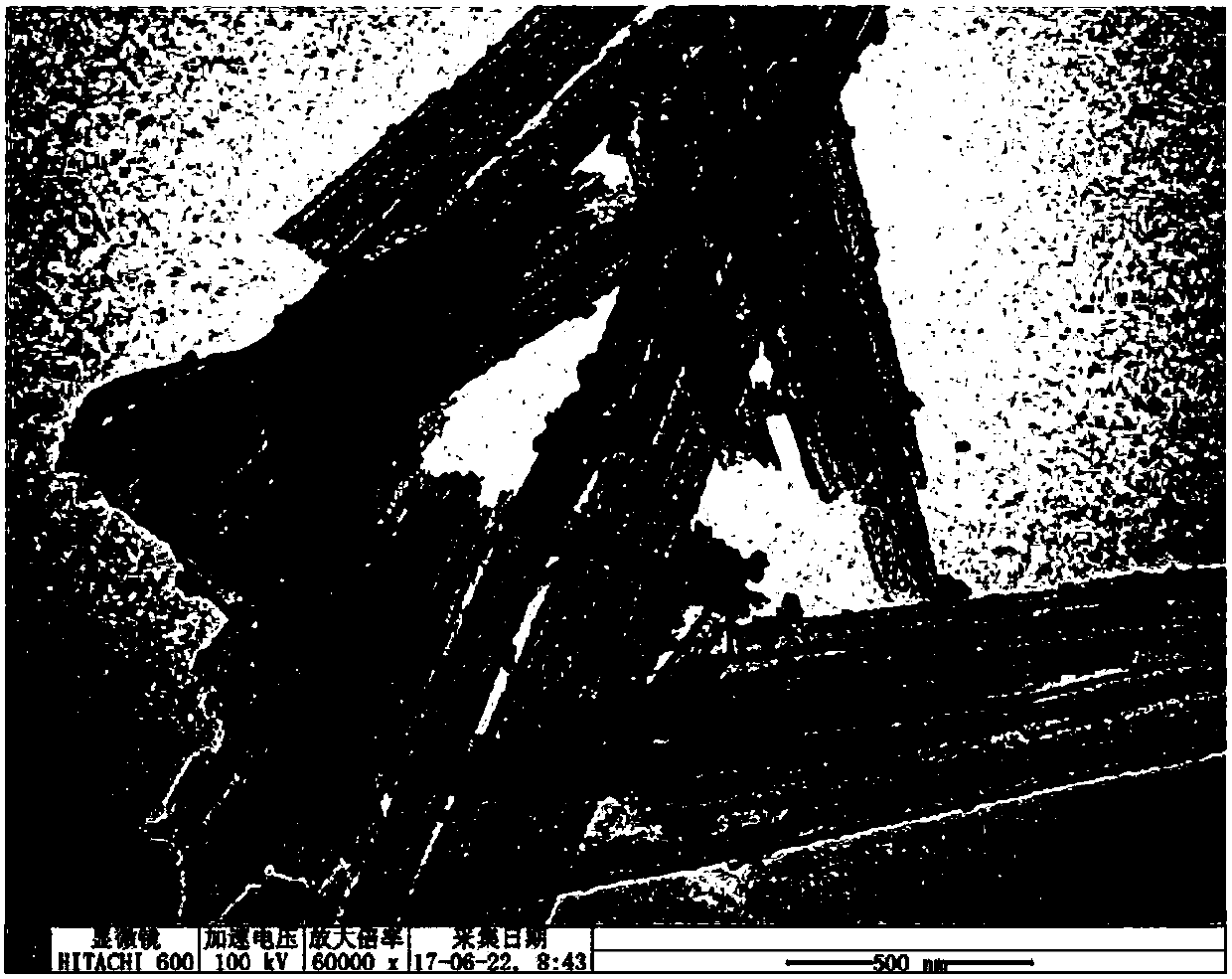

[0024] Raw material ratio: the mass ratio of CdS nanowires to cobalt nitrate is 10:1, and the morphology is shown in the appendix figure 1 .

[0025] 1) Dissolve 50mg of P123, 120mg of Tris and 0.01g of cobalt nitrate in 100mL of deionized water, then add 0.10g of CdS nanowires into the above solution, and stir at room temperature;

[0026] 2) Weigh 0.10 g of dopamine and dissolve it in 50 mL of deionized water, add it to the above solution, and stir to react at room temperature;

[0027] 3) Centrifuge the reacted solution, wash it several times with ethanol, and then dry it in an oven to obtain the product;

[0028] 4) Put the obtained product into a quartz boat, program the temperature up to 900° C. under the protection of nitrogen, and heat-treat for 2 hours to obtain a nanoparticle-carbon nanotube composite material co-doped with cobalt and nitrogen.

Embodiment 2

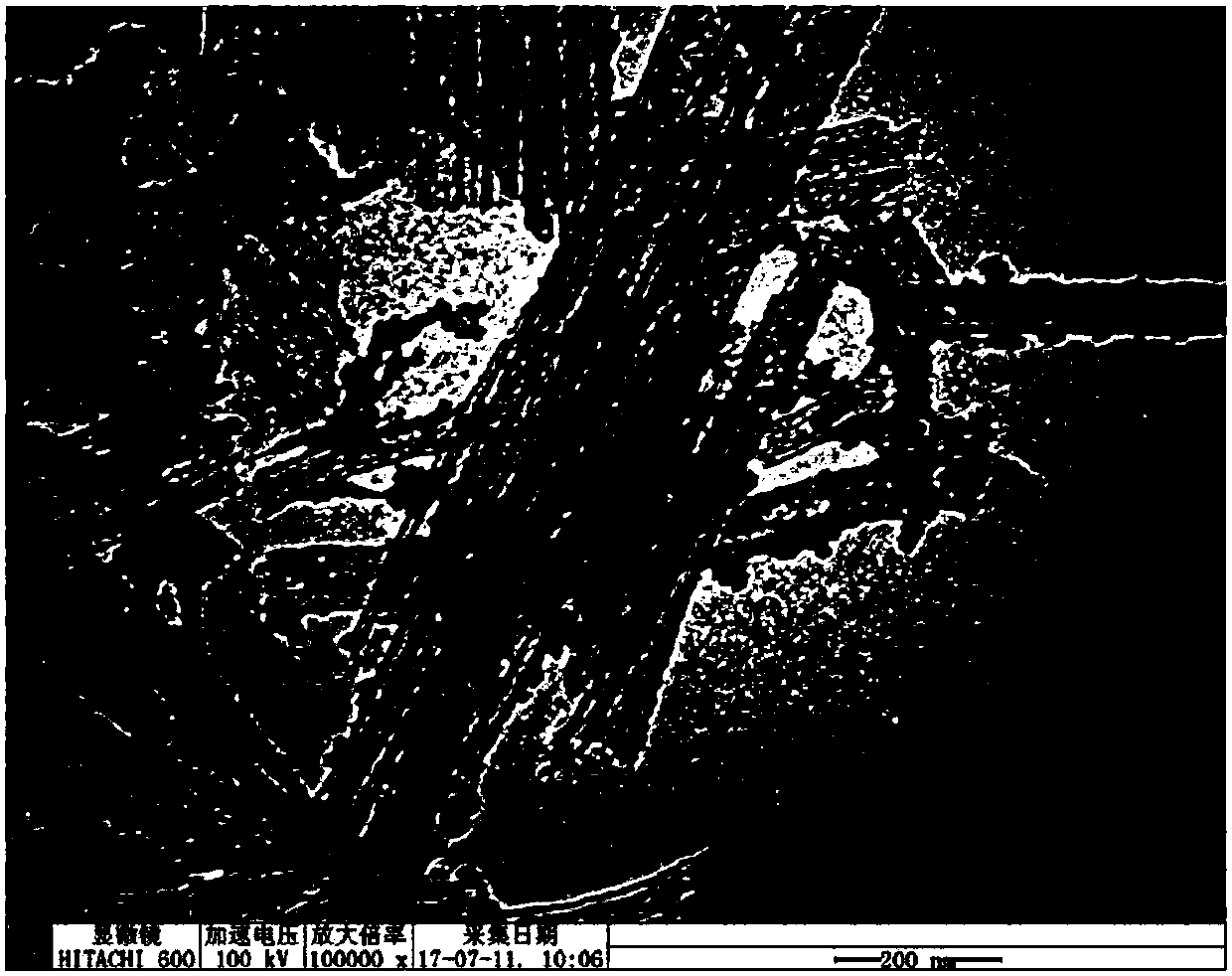

[0030] The ratio of raw materials, the mass ratio of CdS nanowires and cobalt nitrate is 1:1, and the morphology is shown in the appendix figure 2 .

[0031] 1) Dissolve 100mg of P123, 120mg of Tris and 0.10g of cobalt nitrate in 100mL of deionized water, then add 0.10g of CdS nanowires into the above solution, and stir at room temperature;

[0032] 2) Weigh 0.20 g of dopamine and dissolve it in 50 mL of deionized water, add it to the above solution, and stir to react at room temperature;

[0033] 3) Centrifuge the reacted solution, wash it several times with ethanol, and then dry it in an oven to obtain the product;

[0034] 4) Put the obtained product into a quartz boat, program the temperature up to 900° C. under the protection of nitrogen, and heat-treat for 2 hours to obtain a nanoparticle-carbon nanotube composite material co-doped with cobalt and nitrogen.

[0035] It is found by testing that the specific surface area of the composite material prepared in this embo...

Embodiment 3

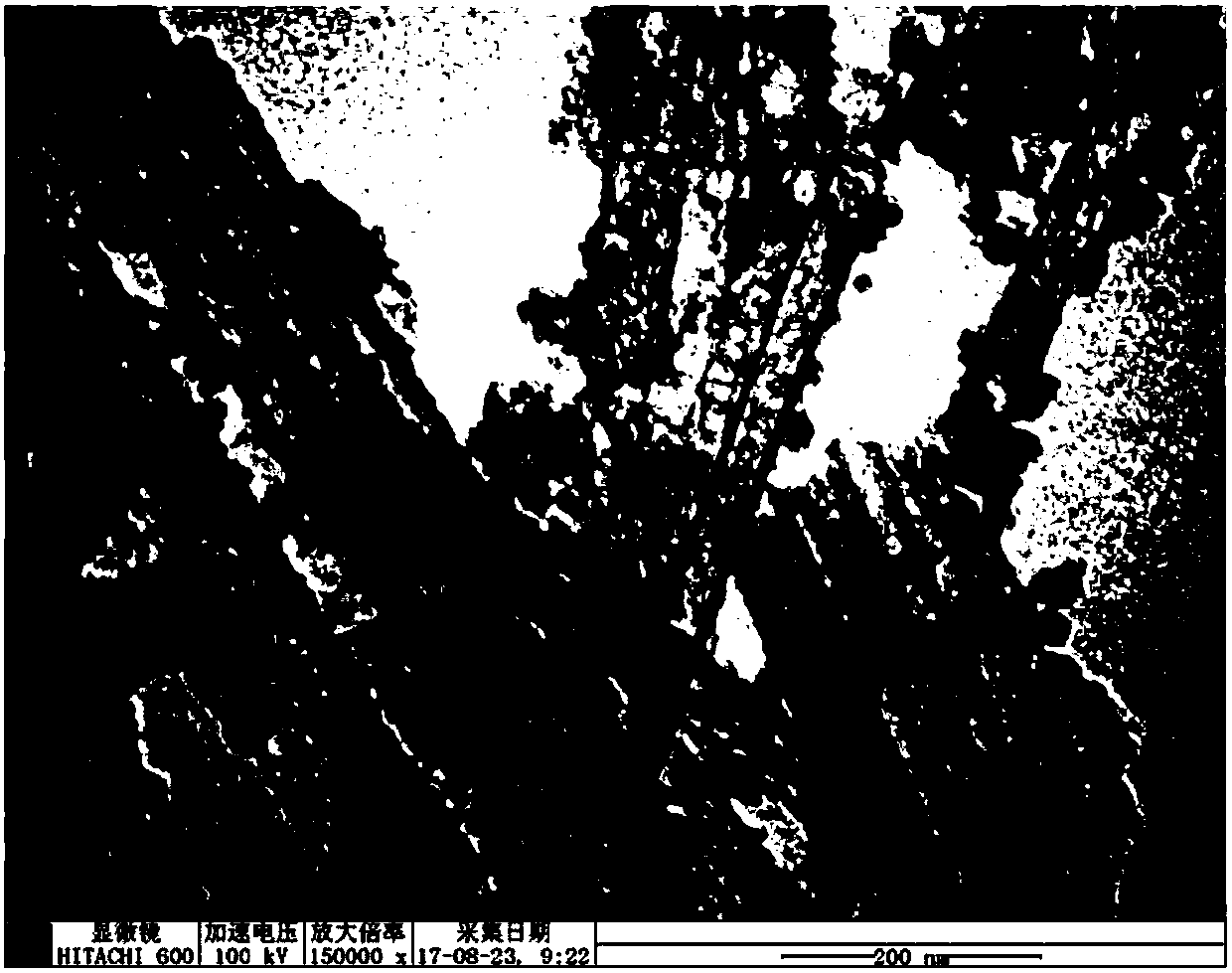

[0037] The ratio of raw materials, the mass ratio of CdS nanowires and cobalt nitrate is 1:2, and the morphology is shown in the appendix image 3 .

[0038] 1) Dissolve 160mg P123, 120mg Tris and 0.60g cobalt nitrate in 100mL deionized water, then add 0.30g CdS nanowires to the above solution, and stir at room temperature;

[0039] 2) Weigh 0.30g of dopamine and dissolve it in 50mL of deionized water, add it to the above solution, and stir to react at room temperature;

[0040] 3) Centrifuge the reacted solution, wash it several times with ethanol, and then dry it in an oven to obtain the product;

[0041]4) Put the obtained product into a quartz boat, program the temperature up to 900° C. under the protection of nitrogen, and heat-treat for 1 hour to obtain a nanoparticle-carbon nanotube composite material co-doped with cobalt and nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com