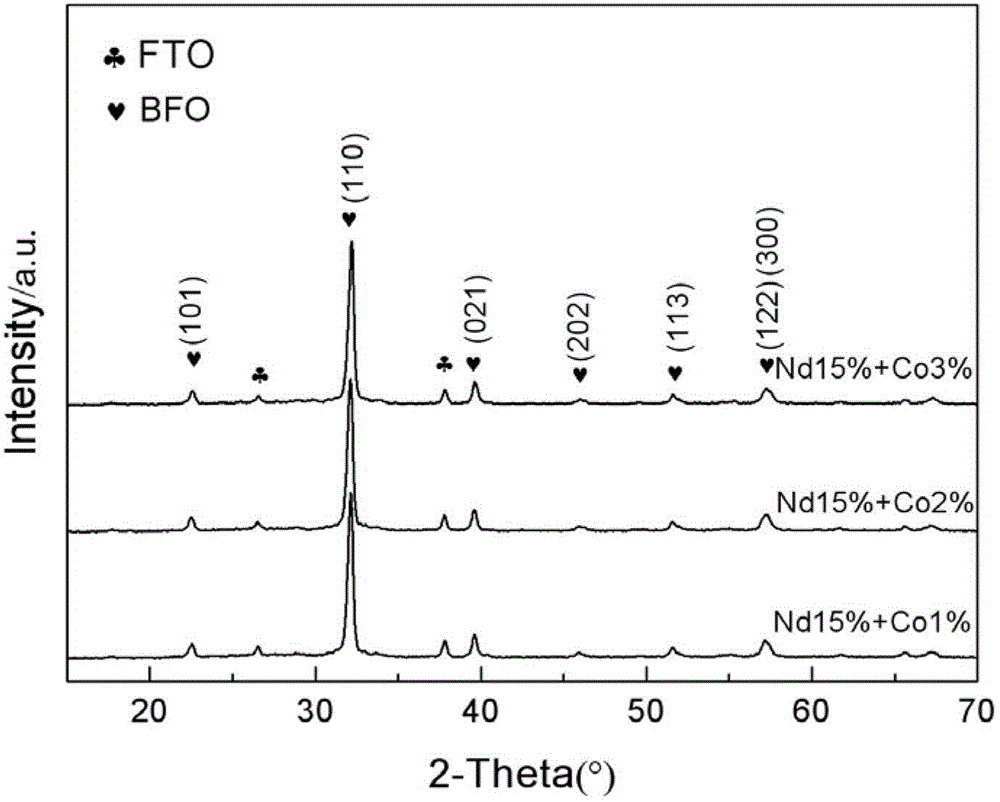

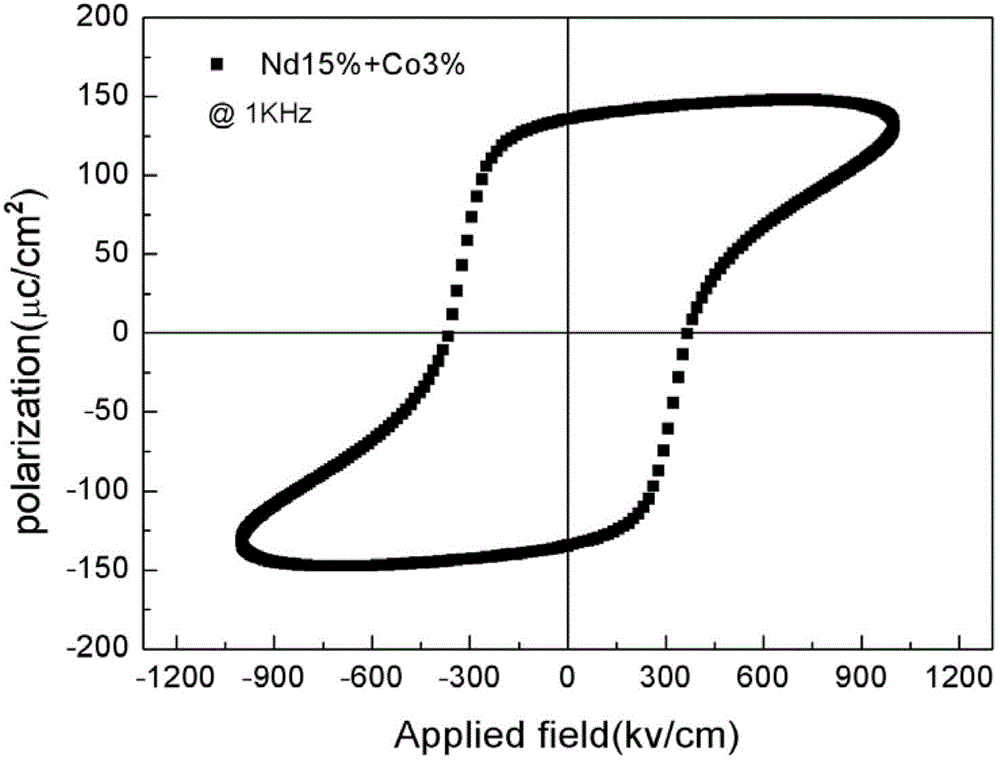

Method for preparing high-remanent-polarization BiFeO3 film with preferentially growing (110) crystal face by sol-gel process

A technology of sol-gel method and polarization strength, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem that ferroelectricity cannot be correctly measured for saturation polarization, it is difficult to observe hysteresis loops, and low Dielectric constant and other issues, to achieve the effect of aggravated structural distortion, easy control, and improved ferroelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 0.90:0.99:0.15:0.01, and magnetically stirred for 2 hours to obtain a stable metal ion concentration of 0.3mol / L BiFeO 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.

[0016] Step 2: Spin-coat BiFeO on FTO / glass substrate by spin-coating method 3 Precursor solution to prepare film, uniform glue at 4000r / min for 15s, after the glue is finished, bake at 200°C for 10~15min to get a dry film, then quickly anneal at 550°C for 6~8min, cool down naturally, repeat the above process to get the desired thickness film.

[0017] In crystalline BiFeO 3 Preparation of 0.502mm thin film surface by ion sputtering 2 The Au electrode is kept at 300°C for 20 minutes to make the electrode and the substrate fully contact. Det...

Embodiment 2

[0019] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 0.90:0.98:0.15:0.02, and magnetically stirred for 2 hours to obtain a stable metal ion concentration of 0.3mol / L BiFeO 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.

[0020] Step 2: Spin-coat BiFeO on FTO / glass substrate by spin-coating method 3 Precursor solution to prepare film, uniform glue at 4000r / min for 15s, after the glue is finished, bake at 200°C for 10~15min to get a dry film, then quickly anneal at 550°C for 6~8min, cool down naturally, repeat the above process to get the desired thickness film.

[0021] In crystalline BiFeO 3 Preparation of 0.502mm thin film surface by ion sputtering 2 The Au electrode is kept at 300°C for 20 minutes to make the electrode and the substrate fully contact. Dete...

Embodiment 3

[0023] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 0.90:0.97:0.15:0.03, and magnetically stirred for 2 hours to obtain a stable metal ion concentration of 0.3mol / L BiFeO 3Precursor solution, wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.

[0024] Step 2: Spin-coat BiFeO on FTO / glass substrate by spin-coating method 3 Precursor solution to prepare film, uniform glue at 4000r / min for 15s, after the glue is finished, bake at 200°C for 10~15min to get a dry film, then quickly anneal at 550°C for 6~8min, cool down naturally, repeat the above process to get the desired thickness film.

[0025] In crystalline BiFeO 3 Preparation of 0.502mm thin film surface by ion sputtering 2 The Au electrode is kept at 300°C for 20 minutes to make the electrode and the substrate fully contact. Deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com