Cobalt-iron bimetal in-situ doped MCM-41 catalyst, and preparation method and application thereof

A MCM-41, in-situ doping technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex MCM-41 catalyst process, uneven metal dispersion, poor stability, etc. Increase activation effect, rich pores, and efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

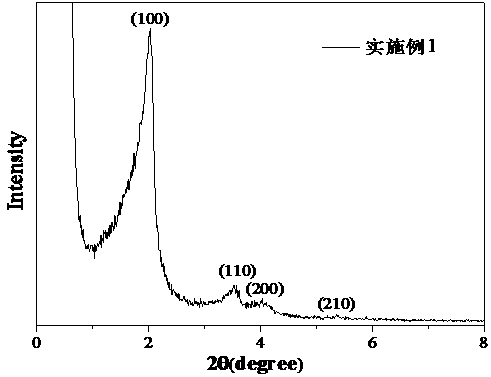

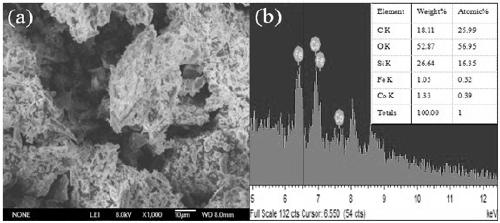

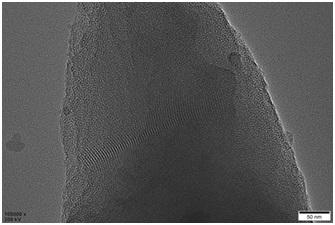

Embodiment 1

[0032] One, the preparation method of cobalt-iron bimetallic in-situ doped MCM-41 catalyst of the present embodiment comprises the following steps:

[0033] 1. Weigh 0.1182g Fe(NO 3 ) 3 9H 2 O and 0.0804g Co(NO 3 ) 2 ·6H 2 O was dissolved in ethanol-deionized water mixed solution (deionized water volume was 5 mL, ethanol was 2 mL), and ultrasonic treatment was performed for 5 min to prepare metal precursor solution A.

[0034] 2. Weigh 1.216g of cetyltrimethylammonium bromide (CTAB) and 0.222g of sodium hydroxide and dissolve in 50mL of deionized water, stir in a water bath at 35°C for 30min, and sonicate for 2h to form solution B.

[0035] 3. Add 6.2mL tetraethyl orthosilicate (TEOS)-ethanol mixed solution (volume of tetraethyl orthosilicate: 6.2mL, ethanol: 3mL) drop by drop while stirring under hydrothermal conditions at 35°C. Stir at room temperature for 2h.

[0036] 4. The metal precursor solution A was added dropwise to the gel C, and then poured into a polytetraf...

Embodiment 2

[0046] One, the preparation method of cobalt-iron bimetallic in-situ doped MCM-41 catalyst of the present embodiment comprises the following steps:

[0047] 1. Weigh 0.1182g Fe(NO 3 ) 3 9H 2 O and 0.0804g Co(NO 3 ) 2 ·6H 2 O was dissolved in ethanol-deionized water mixed solution (deionized water volume 5mL, ethanol 2mL), and sonicated for 5min to prepare metal precursor solution A.

[0048] 2. Weigh 1.621g CTAB and 0.2775g sodium hydroxide and dissolve in 50mL deionized water, stir in a water bath at 35°C for 30min, and ultrasonicate for 2h to form solution B.

[0049] 3. Add tetraethyl orthosilicate (TEOS)-ethanol mixed solution drop by drop while stirring under hydrothermal conditions at 40°C (volume of orthosilicate is 6.2mL, and ethanol is 3mL) to form gel C, then cool down to room temperature and stir 2h.

[0050] 4. Add the metal precursor solution A to the gel C dropwise, pour the gel into a polytetrafluoroethylene-lined reactor, and crystallize at 120°C for 72 ...

Embodiment 3

[0058] One, the preparation method of cobalt-iron bimetallic in-situ doped MCM-41 catalyst of the present embodiment comprises the following steps:

[0059] 1. Weigh 0.1182g Fe(NO 3 ) 3 9H 2 O and 0.0804g Co(NO 3 ) 2 ·6H 2 O was dissolved in ethanol-deionized water mixed solution (deionized water volume 5mL, ethanol 2mL), and sonicated for 5min to prepare metal precursor solution A.

[0060] 2. Weigh 2.027g CTAB and 0.2775g sodium hydroxide and dissolve in 50mL deionized water, stir in a water bath at 30°C for 30min, and ultrasonicate for 2h to form solution B.

[0061] 3. Add tetraethyl orthosilicate (TEOS)-ethanol mixed solution drop by drop while stirring under hydrothermal conditions at 35°C (volume of orthosilicate is 6.2mL, ethanol is 3mL) to form a gel C, then cool down to room temperature and stir 2h.

[0062] 4. Add metal precursor solution A dropwise to gel C, pour gel C into a polytetrafluoroethylene-lined reactor, and crystallize at 150°C for 48 hours.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com