New method for preparing LaCoO3/SBA-16 and LaMnO3/SBA-16 catalyst

A technology of SBA-16 and catalyst, applied in the field of preparing LaCoO3/SBA-16 and LaMnO3/SBA-16 catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

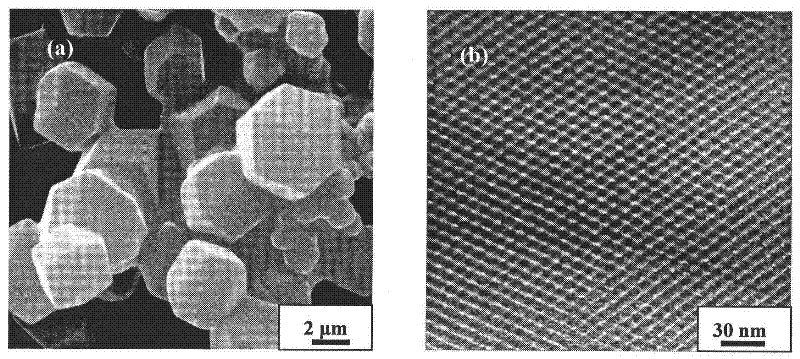

[0015] Example 1: The specific preparation method of polyhedral ordered mesoporous SBA-16 (refer to patent ZL200710118755.1) is: at room temperature, add 1.2288gEO to 168mL hydrochloric acid (0.4mol / L) solution 106 PO 70 EO 106 and 0.0266g of hexadecyltrimethylammonium bromide, under strong stirring, add 4g of ethyl orthosilicate to the above solution and stir, transfer to an autoclave and heat at 95°C for 5 days, filter, After washing with deionized water, it was dried at 60 °C for 12 hours, then programmed in a muffle furnace to 550 °C at a rate of 1 °C / min and fired at 550 °C for 3 hours to obtain polyhedral ordered mesoporous SBA- 16, its specific surface area is 1010m 2 / g.

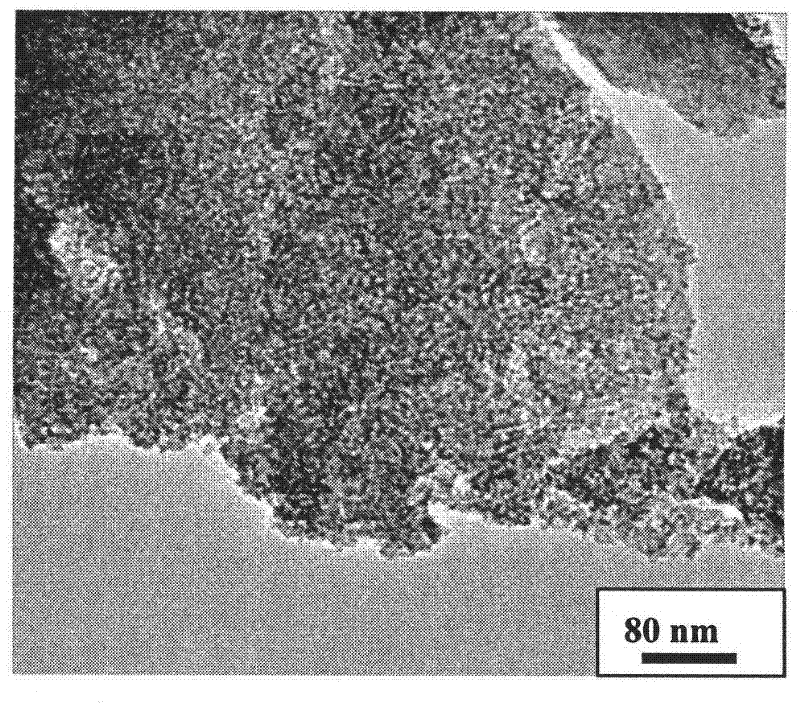

[0016] The carbonization treatment method of SBA-16 is: Weigh 1g of SBA-16, 1.2475g of sucrose and 5.9910mL of water in a beaker, stir and evaporate to dryness, then place in an oven and dry at 80°C and 180°C for 6h respectively. Dissolve 1.2475g of sucrose in 5.9910mL of water and add it to the ...

Embodiment 2

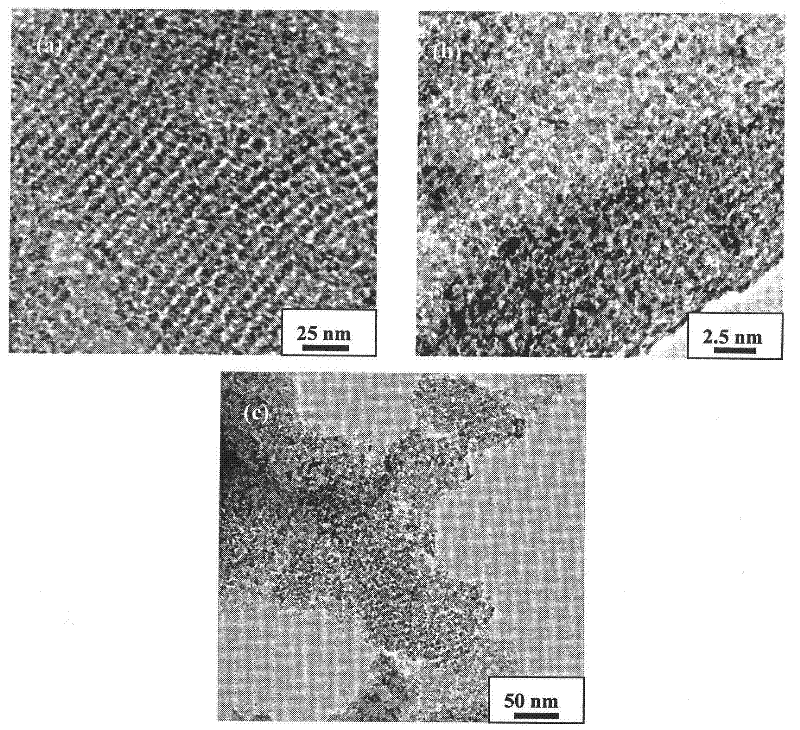

[0018] Embodiment 2: take by weighing 12.99g La(NO 3 ) 3 ·6H 2 O and 6.97mL g Mn(NO 3 ) 2 (50%) solution and 1.5507 g of citric acid were placed in a beaker, 8 mL of methanol was added, and after magnetic stirring for 2 h, a certain amount of deionized water was added to make the volume to 25 mL. The above mixture was poured into a beaker containing 0.3 g of the carbon-containing mesoporous SBA-16 of Example 1. Under ultrasonic radiation, the mixed solution was impregnated with carbon-containing mesoporous SBA-16 for about 5 hours and filtered, and the sample obtained was dried at room temperature for 12 hours, and then the sample was loaded into a magnetic boat in a tube furnace, N 2 Rise from room temperature to 700°C at a rate of 1°C / min in the atmosphere, and keep at 700°C for 4 hours, then drop to 50°C, change to air atmosphere, and rise from 50°C to 750°C at a rate of 1°C / min, And keep it at 750℃ for 4h to get LaMnO with mesoporous structure 3 / SBA-16 catalyst, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com