Preparation method for Cu-Co-S-MOF nanosheet and application thereof

A cu-co-s-mof, nanosheet technology, applied in the fields of electrochemistry and nanomaterials, can solve the problems of low special capacity and rate performance, inability to implement industrial application, limited capacitance performance, etc., and achieve good redox performance, The effect of low cost and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, a cobalt-based metal-organic framework (Co-MOF) was grown on nickel foam (1 cm×1 cm) by a solution method: 0.05 M cobalt nitrate hexahydrate was dissolved in 40 ml of deionized water, which was called solution A. 0.4M 2-methylimidazole was dissolved in 40ml of deionized water, called solution B. Solution A and solution B were mixed and stirred rapidly, and then put into clean nickel foam to react for 4 hours at room temperature. After the reaction, the nickel foam with Co-MOF was rinsed with ethanol and deionized water, and dried in a drying oven at 60 °C.

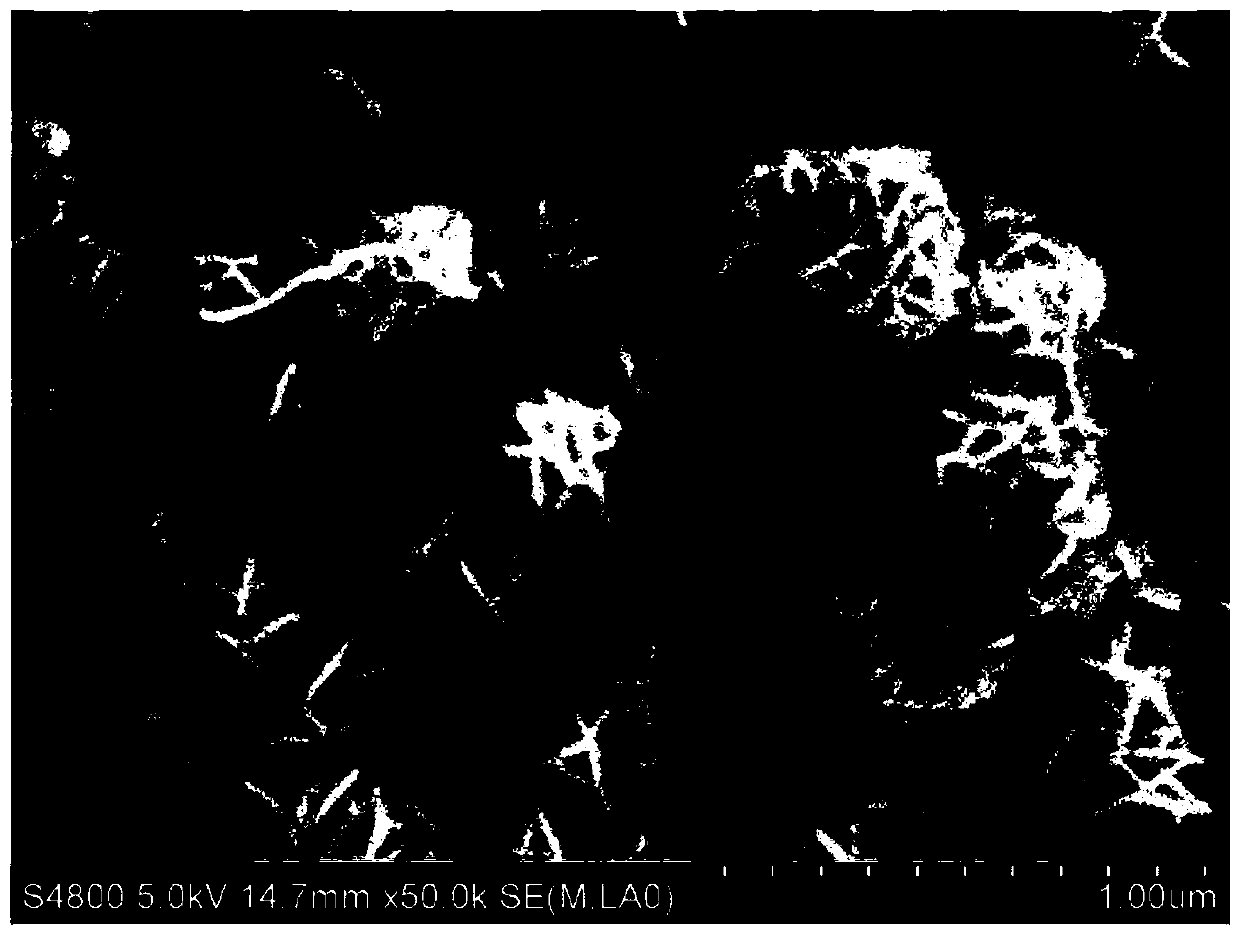

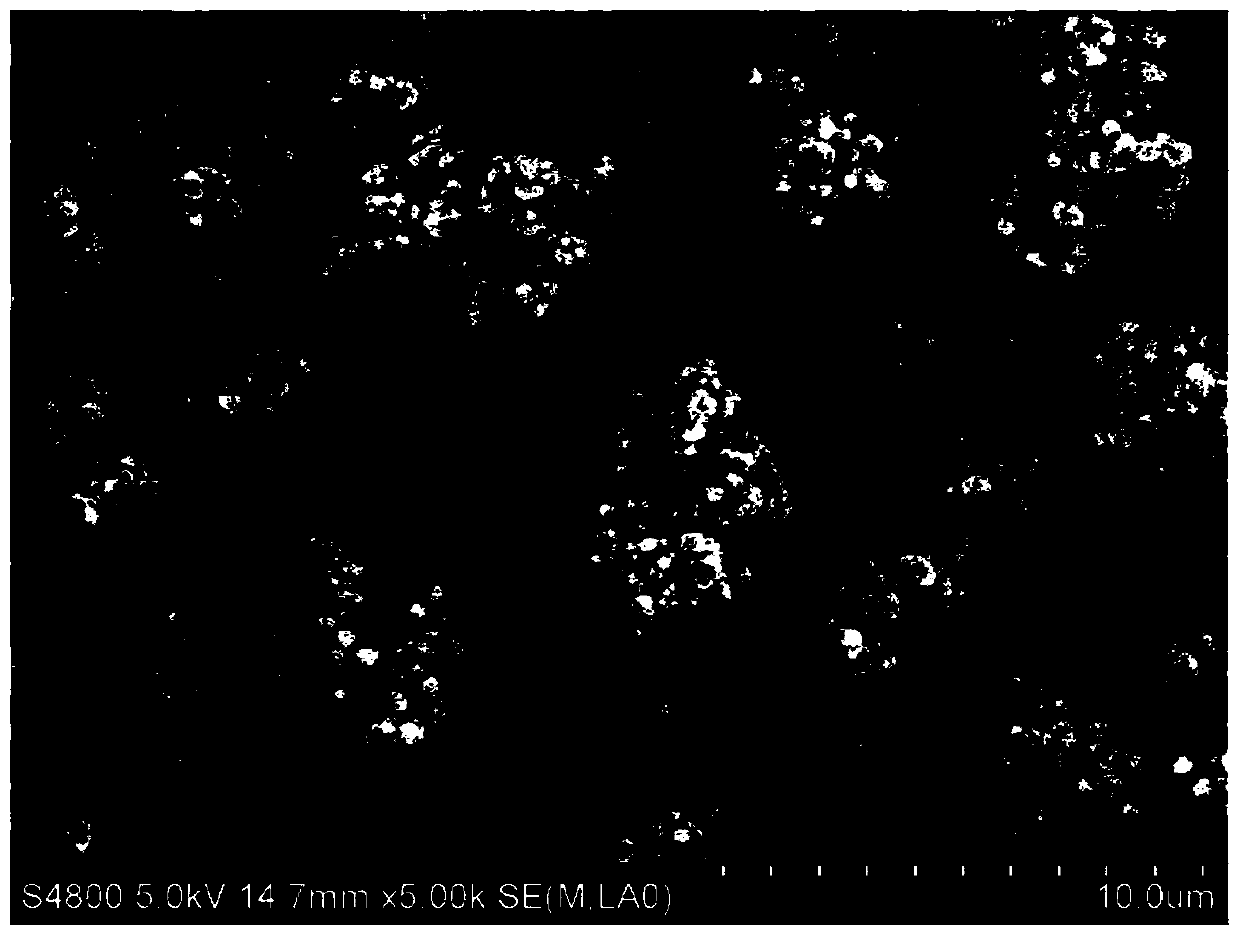

[0029] Secondly, 0.5mmol copper nitrate hexahydrate and 1mmol cobalt nitrate hexahydrate were dissolved in 5ml isopropanol, and mixed solution C was obtained after they were completely dissolved, and 120 μl carbon disulfide and 1ml pentamethyldiethylenetriamine (PMDTA) were added to obtain Mix solution D, and immerse the nickel foam with Co-MOF in the mixed solution D, and then quickly transfer it to a polyt...

Embodiment 2

[0032] The cleaned nickel foam was prepared for use in the following experiments (the clean nickel foam was selected as the substrate here, and the nickel foam with Co-MOF was used as the substrate in Example 1). Dissolve 0.5mmol of copper nitrate hexahydrate and 1mmol of cobalt nitrate hexahydrate in 5ml of isopropanol, after they are completely dissolved, add 120μl of carbon disulfide and 1ml of pentamethyldiethylenetriamine (PMDTA), and put the clean foam Nickel was immersed in the solution, and then it was quickly transferred to a polytetrafluoroethylene hydrothermal kettle for solvothermal reaction at 150°C for 8h. After the reaction is completed and cooled to room temperature, the CuCo 2 S 4 The foamed nickel was taken out, washed three times with deionized water and ethanol in turn, and then placed in a vacuum drying oven at 60°C for 12h.

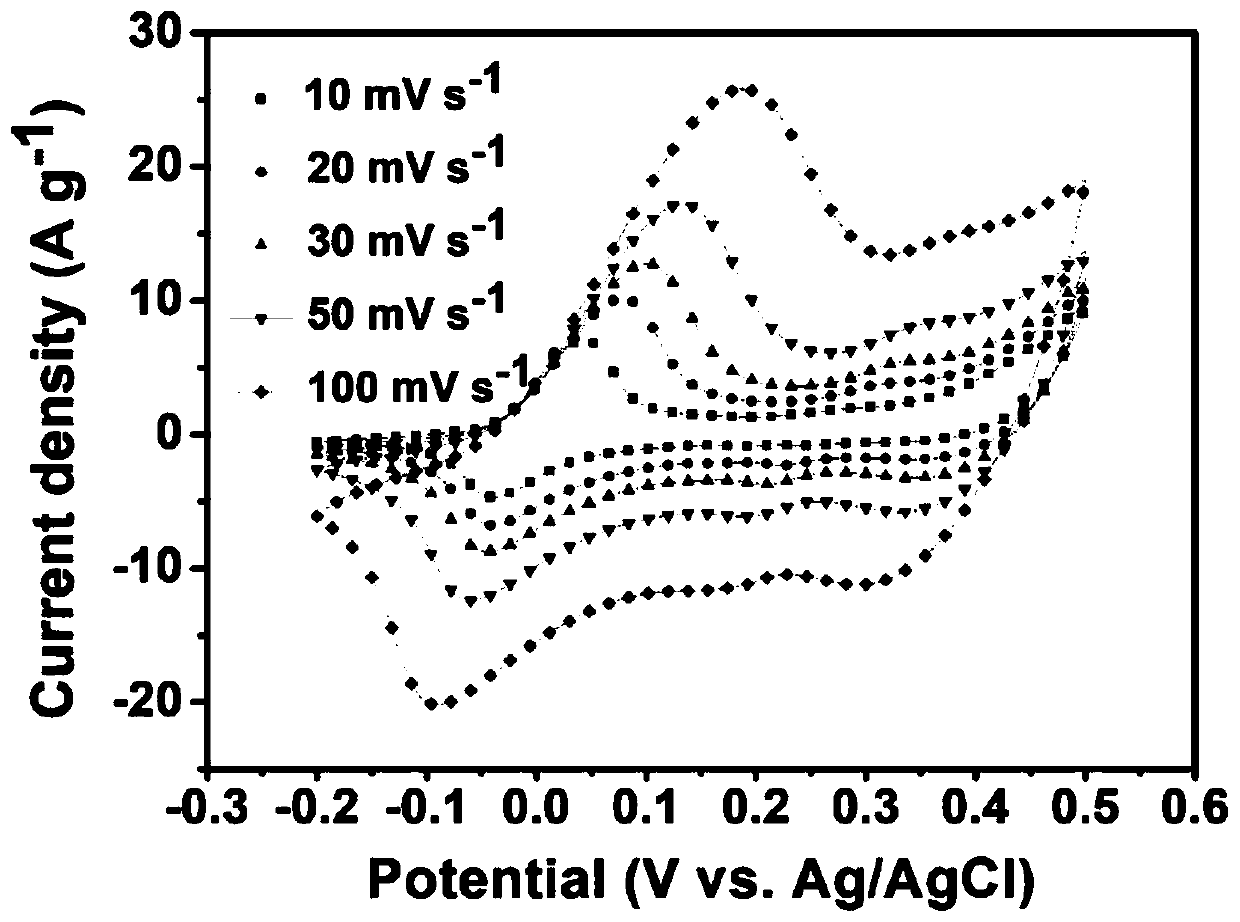

[0033] The Chenhua CHI760e electrochemical workstation adopts cyclic voltammetry and constant current charge and discharge method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com