Cobalt-nickel/silica aerogel composite microwave absorb material and preparation method thereof

A composite wave absorbing material and silica technology, applied in the field of wave absorbing materials, can solve the problems of fragility, few reports on the wave absorbing properties of metal aerogel composite materials, singleness, etc., and achieve the effect of enhancing the wave absorbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A cobalt-nickel / silicon dioxide airgel composite wave-absorbing material comprises silicon dioxide airgel and cobalt, nickel and cobalt-nickel alloy magnetic metal grown on the silicon dioxide airgel in situ.

[0028] The composite wave-absorbing material includes 1-25 parts of cobalt, nickel and cobalt-nickel alloy magnetic metal and 75-99 parts of silicon dioxide aerogel, wherein each of the above components is by mass.

[0029] Cobalt, nickel, and cobalt-nickel alloy magnetic metals can be grown in the form of nanowires in silica airgel materials.

[0030] The present invention also provides a preparation method of a cobalt-nickel / silica airgel composite wave-absorbing material, comprising the following steps:

[0031] Step 1: Mix cobalt nitrate, nickel nitrate, ethylene glycol, tetraethyl orthosilicate, and phosphoric acid, and stir to form a mixed solution, wherein the stirring temperature is 90°C;

[0032] Step 2: After cooling the mixed solution, add isopropanol...

Embodiment 2

[0044] In this embodiment, the molar ratio of cobalt nitrate, nickel nitrate, ethylene glycol, tetraethylorthosilicate, and phosphoric acid in step 1 is 0.08:0.02:4:1:1x10 -3 , using a magnetic stirring device to stir for 10 hours; the mol ratio of the addition of isopropanol and deionized water to ethyl orthosilicate in step 2 is 3:4:1; in step 2, the N,N-dimethylacetamide The molar ratio of the added amount to cobalt nitrate and nickel nitrate is 10:4:1. Other than that, it was the same as in Example 1.

[0045] Through the above steps, the metal content in the prepared absorbing material is 5%, and the specific surface area is 676.5m 2 / g, when the thickness of the composite material is 2mm, the peak reflectivity in the range of 2-18GH can reach -20dB.

Embodiment 3

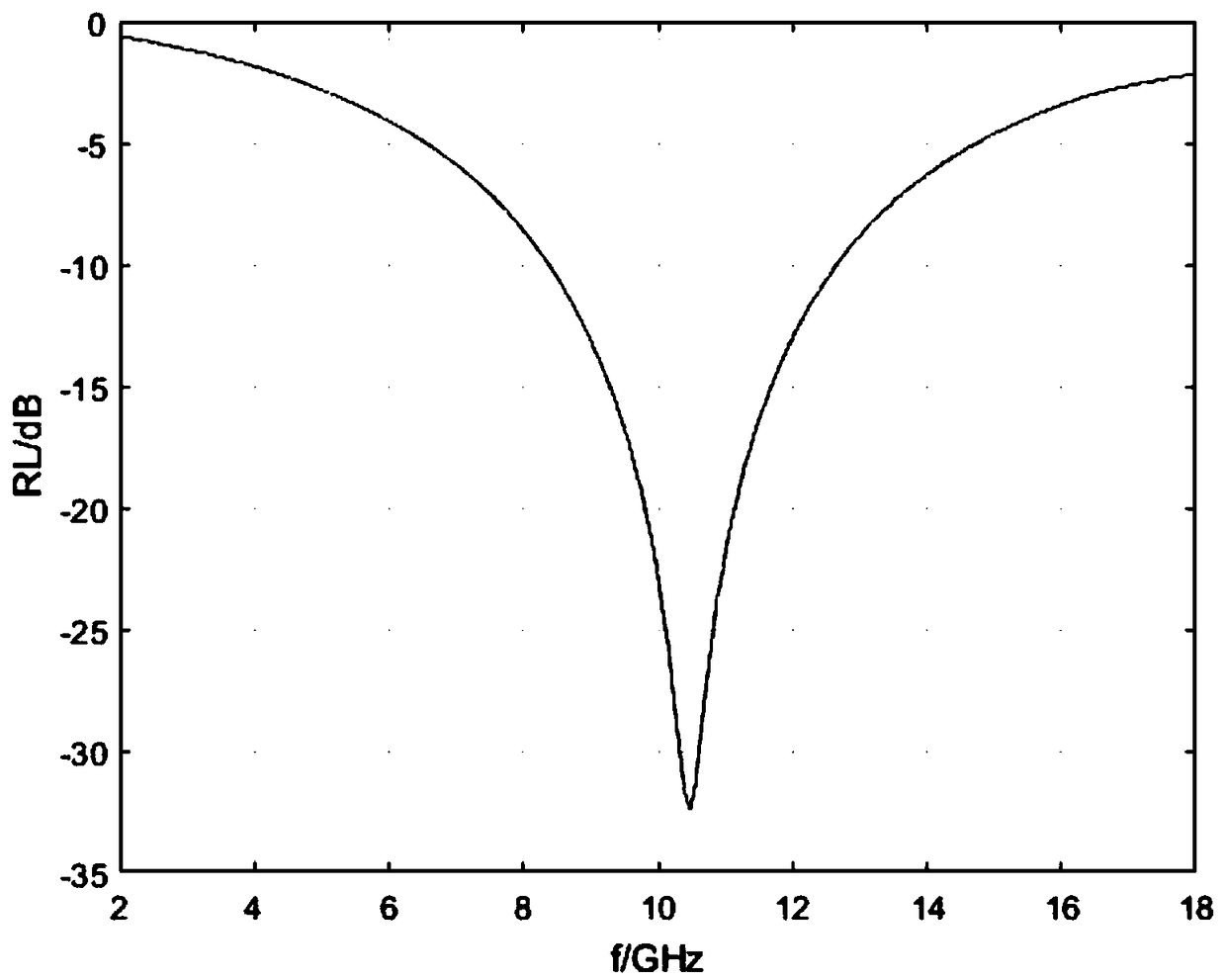

[0047] as attached figure 1 As shown, in the present embodiment, the molar ratio of cobalt nitrate, nickel nitrate, ethylene glycol, orthosilicate, phosphoric acid in step 1 is 0.25:0.25:5:1:1x10 -3 , using a magnetic stirring device to stir for 10 hours; the mol ratio of the addition of isopropanol and deionized water to ethyl orthosilicate in step 2 is 3:4:1; in step 2, the N,N-dimethylacetamide The molar ratio of the added amount to cobalt nitrate and nickel nitrate is 2:1:1. Other than that, it was the same as in Example 1.

[0048] Through the above steps, the metal content in the prepared absorbing material is 22%, and the specific surface area is 390.6m 2 / g, when the thickness of the composite material is 2mm, the peak reflectivity in the range of 2-18GH can reach -32dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com