Honeycomb porous graphene and preparation method thereof

A porous graphene and honeycomb technology, applied in the field of honeycomb porous graphene and its preparation, can solve the problems of porous structure distribution control, poor distribution uniformity, easy agglomeration of graphene, etc., achieve less heteroatom defects, prevent agglomeration, Strong coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of honeycomb porous graphene, comprises the following steps:

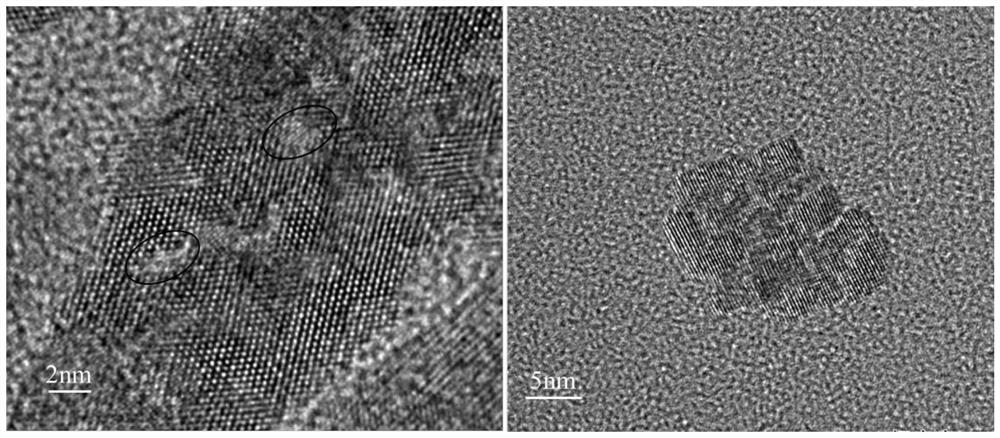

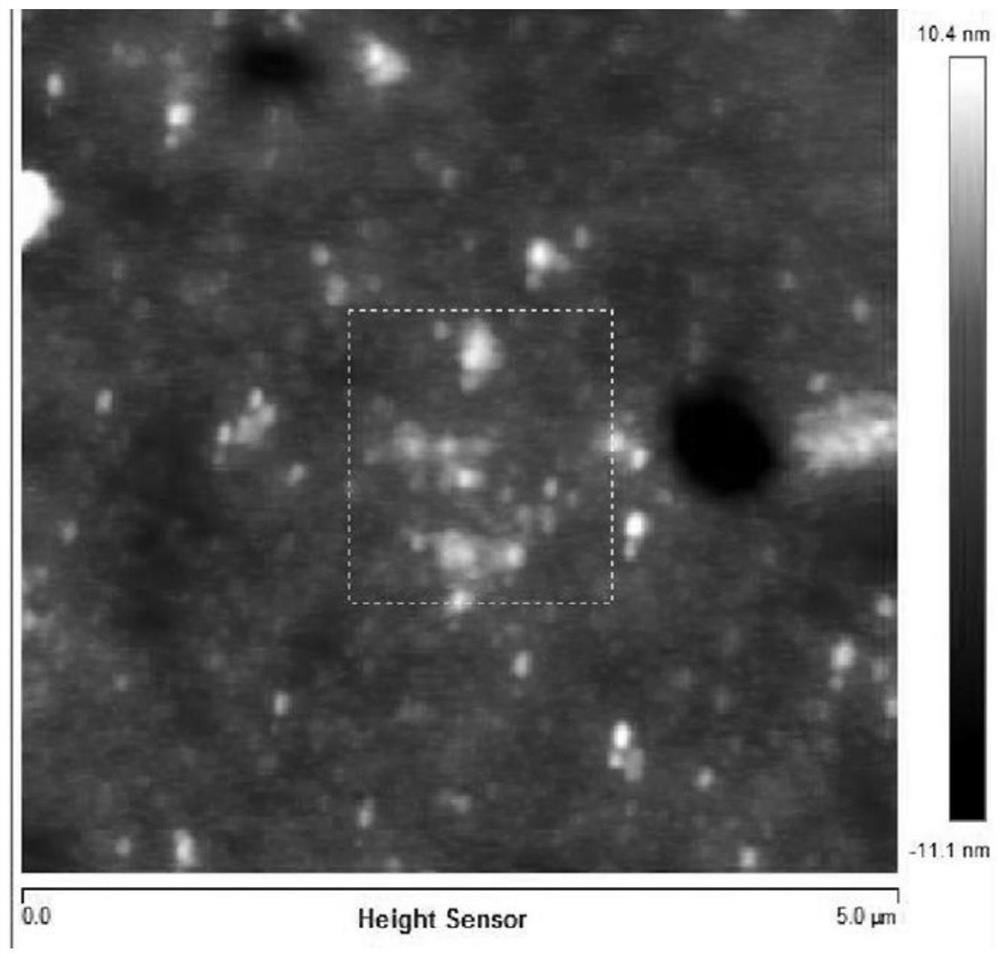

[0031] S1. Ultrasonically disperse graphene oxide sheets with a lateral size of 0.2-1 μm in a solvent, then add a metal salt solution to make it coordinate and balance in the solution, and then centrifuge to obtain graphene oxide-metal ion ligands. The carboxyl group and carbonyl group on the surface of graphene oxide are easy to form coordination bonds with metal ions, and the obtained graphene oxide-metal ion ligand has excellent microwave absorption ability.

[0032] As a further improvement of the present invention, in step S1, the graphene oxide sheet is a nitrogen-doped graphene oxide sheet. Nitrogen-doped graphene oxide sheets are selected, which have a stronger coordination with metal salts, and the prepared nitrogen-doped graphene oxide-metal ion ligands have stronger microwave absorption capabilities, so microwave irradiation plasma etching The e...

Embodiment 1

[0044] A preparation method of honeycomb porous graphene, comprising the following steps:

[0045] S1. Ultrasonic disperse graphene oxide sheets with a lateral size of 0.2 μm and a thickness of 3 nm (the carbon atomic mass content is about 80%) in deionized water, and then add Co(NO 3 ) 2 ·6H 2 O solution, after making it coordinated and balanced in the solution, centrifuged to obtain the graphene oxide-metal ion ligand;

[0046] S2. the graphene oxide-metal ion ligand is dispersed in a quartz beaker containing a mixed solvent composed of deionized water and ethanol with a volume ratio of 1:5, and then adding benzene to the quartz beaker while ultrasonically dispersing , until the volume ratio of the sum of benzene, water and ethanol is 8:1, obtaining a graphene oxide-metal ion ligand reaction solution with a concentration of 20g / L;

[0047] S3. put the quartz beaker filled with the reaction solution in step S2 in the microwave liquid phase discharge device, feed argon into...

Embodiment 2-7

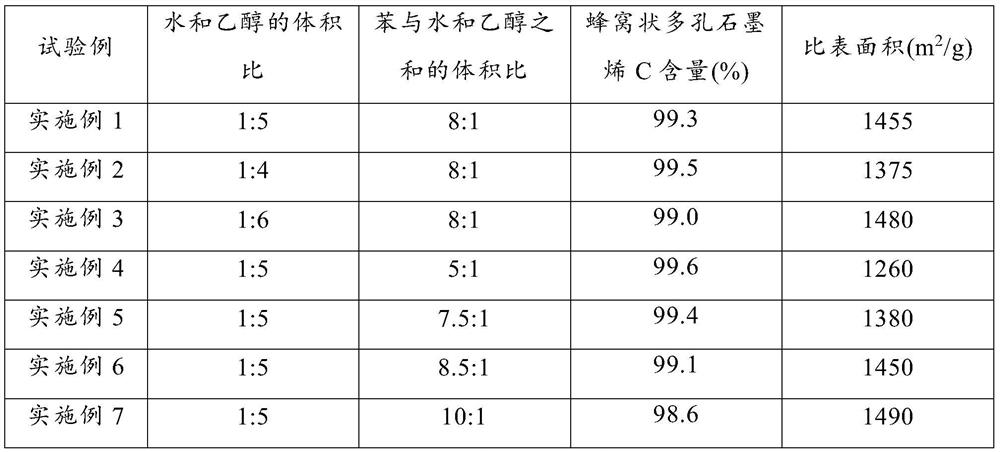

[0052] A kind of preparation method of honeycomb porous graphene, compared with embodiment 1, difference is that in step S2, the volume ratio of deionized water and ethanol and the volume ratio of the sum of benzene and water and ethanol are shown in table 1 Show. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0053] Table 1 Preparation conditions and performance parameters of Examples 1-7

[0054]

[0055] It can be seen from Table 1 that with the increase of deionized water content in the solvent, the C content of the obtained honeycomb porous graphene gradually increases, indicating that the degree of reduction gradually increases, and the heteroatom defects gradually decrease, but the specific surface area also gradually increases. This may be due to the fact that water molecules are easy to absorb microwaves, resulting in the reduction of microwave absorption by graphene oxide and affecting the occurrence of microwave liquid pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com