Preparation method for nitrogen-containing hierarchical porous carbon nano tube film

A technology of hierarchical porous carbon and nanotube membranes, applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems that the fiber space cannot be fully utilized, the pore structure cannot be effectively regulated, and the uncontrollability can achieve mass transfer. Improved performance and channel utilization, elimination of adverse effects, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

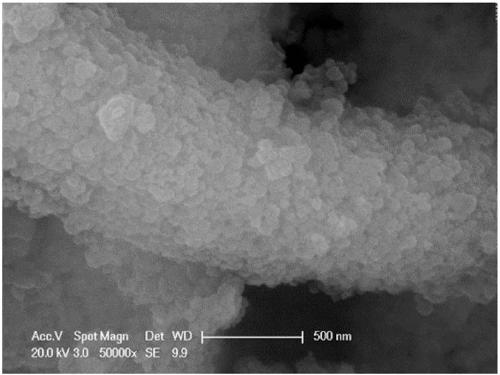

[0109] According to one embodiment of the present application, Zn(acac) 2 Dissolved in N,N-dimethylformamide simultaneously with polyacrylonitrile as spinning solution, wherein polyacrylonitrile and Zn(acac) in spinning solution 2 The mass fractions of both are 10%, stirred at 70°C for 24h to fully dissolve to obtain a clear and transparent solution. Then the above-mentioned solution of 10mL is placed in the syringe, under the condition of 10KV voltage, 25 ℃, relative humidity 10%, carry out spinning, the distance of syringe needle point and receiving plate is 5cm, obtains containing Zn(acac) 2 polyacrylonitrile nanofiber membrane. The resulting Zn(acac) 2 The polyacrylonitrile nanofiber membrane was pre-oxidized in air at 300°C for 2h, then calcined in air at 1000°C for 2h to remove polyacrylonitrile, and dried to obtain a ZnO nanofibrous web.

[0110] Place the above ZnO nanofibrous web in 100mL, 3mol / L dimethylimidazole solution (solvent is N,N-dimethylformamide), soak a...

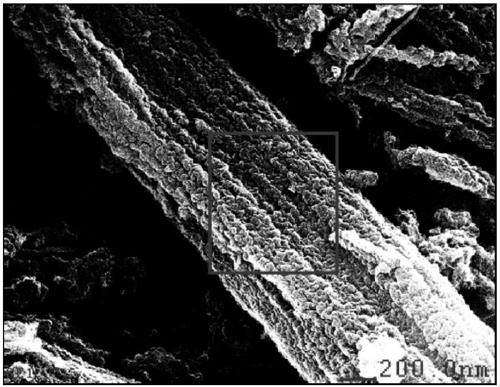

Embodiment 2

[0112] According to one embodiment of the present application, Zn(acac) 2 Dissolve in water with polyvinyl alcohol as a spinning solution, wherein polyvinyl alcohol and Zn(acac) in the spinning solution 2 The mass fraction of each is 15%, stirred at 80°C for 24h to fully dissolve to obtain a clear and transparent solution. Then the above-mentioned solution of 10mL is placed in the syringe, under the condition of 15KV voltage, 30 ℃, relative humidity 10%, carry out spinning, the distance of syringe needle point and receiving plate is 10cm, obtains containing Zn(acac) 2 polyvinyl alcohol nanofiber membrane. The resulting Zn(acac) 2 The polyvinyl alcohol nanofiber membrane was pre-oxidized in air at 250°C for 2h, then calcined in air at 800°C for 1.5h to remove polyvinyl alcohol, and dried to obtain a ZnO nanofibrous web.

[0113] Place the above ZnO nanofibrous web in 100mL, 2mol / L dimethylimidazole solution (solvent is N,N-dimethylformamide), soak at 80°C for 20h, and dry to...

Embodiment 3

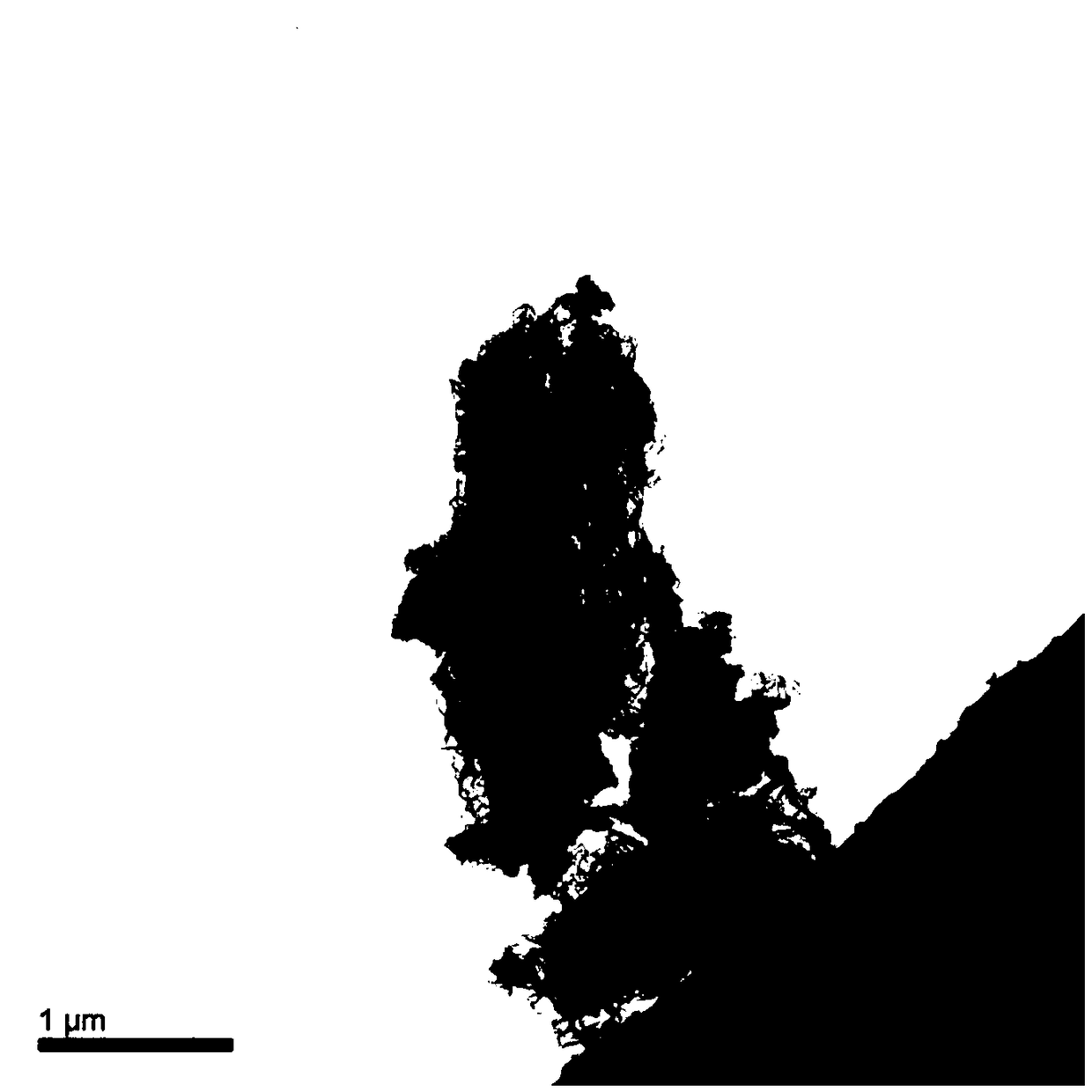

[0115] According to one embodiment of the present application, the Ni(NO 3 ) 2 Dissolved in N,N-dimethylformamide simultaneously with polyacrylonitrile as spinning solution, wherein polyacrylonitrile and Ni(NO 3 ) 2 The mass fraction of each is 20%, stirred at 70°C for 24h to fully dissolve to obtain a clear and transparent solution. Then put 8mL of the above-mentioned solution into the syringe, spin at 20KV voltage, 20°C, and 20% relative humidity, the distance between the needle tip of the syringe and the receiving plate is 10cm, and the Ni(NO 3 ) 2 polyacrylonitrile nanofiber membrane. The resulting Ni(NO 3 ) 2 The polyacrylonitrile nanofiber membrane was pre-oxidized in air at 300°C for 3h, then calcined in air at 900°C for 2h to remove polyacrylonitrile, and dried to obtain a NiO nanofiber web.

[0116] The above-mentioned NiO nanofiber web was placed in 150mL, 1mol / L benzimidazole solution (solvent is absolute ethanol), soaked at 70°C for 24h, and dried to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com