Preparation method of positive electrode material of lithium-sulfur battery, and lithium-sulfur battery

A lithium-sulfur battery and positive electrode material technology, applied in the field of energy storage, can solve the problems of lithium-sulfur battery coulombic efficiency drop, low active material utilization rate, poor cycle performance, etc., to achieve the suppression of shuttle effect, increase battery capacity, and long cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

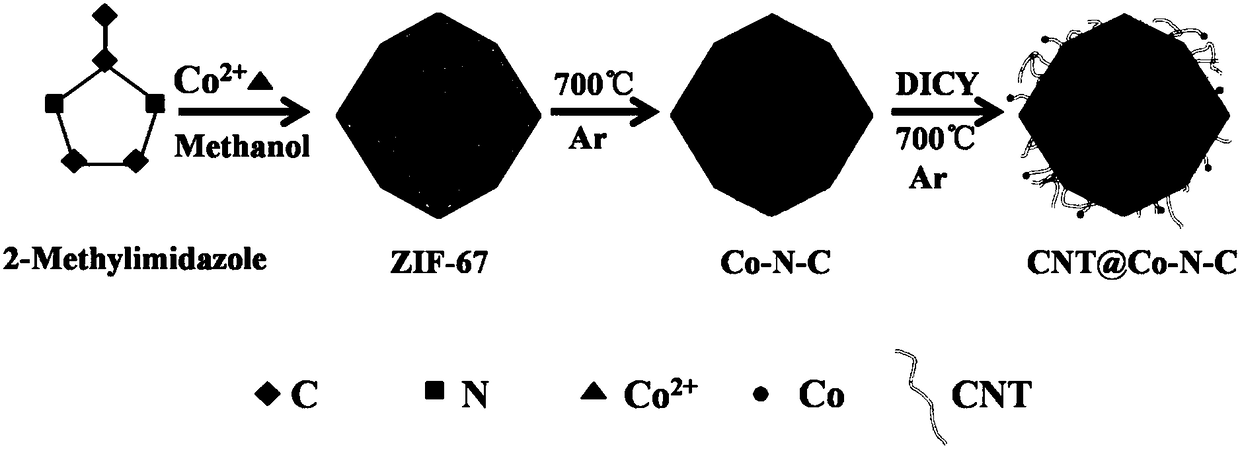

[0034] A kind of preparation method of positive electrode material for lithium-sulfur battery, specific process is as follows figure 1 As shown, it mainly involves four key steps of organic framework molecular construction, metal complexation, element doping and nanotube growth. The specific details are as follows:

[0035] S100. Dissolve cobalt nitrate and 2-methylimidazole in methanol at a ratio of 1:4, and let it stand for 6h-12h, and after centrifugation, dry it in a vacuum drying oven at 60°C-80°C for 12h, wherein , the drying standard is to remove methanol and a small amount of water to obtain ZIF-67; scanning electron microscopy results figure 2 As shown, its crystal structure is a cube.

[0036] S200, carbonizing ZIF-67 at 700°C-900°C at a heating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com