Nanometer copper-based catalyst and preparation method thereof

A catalyst and nano-copper technology, applied in the field of chemistry, can solve the problems of low catalytic activity and large addition amount, and achieve the effects of increasing catalytic amount, reducing usage amount and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

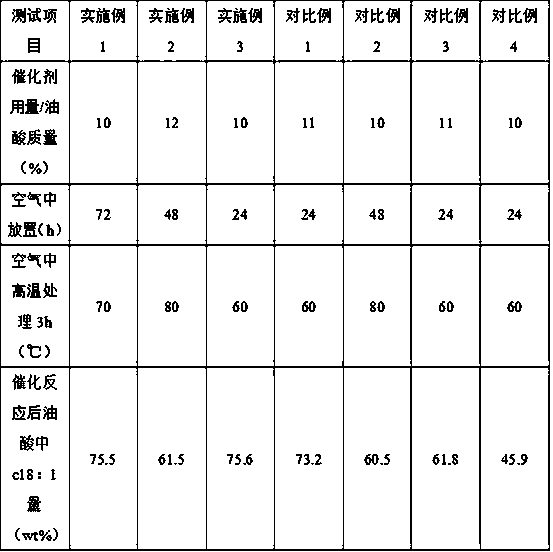

Examples

preparation example Construction

[0029] A preparation method of nanometer copper-based catalyst, comprising the steps of:

[0030] In terms of parts by mass, take 5-8 parts of catalyst active body, 1-3 parts of catalyst precursor, 7-10 parts of magnetic load, and 50-70 parts of absolute ethanol, mix them, and ultrasonically disperse them for 20-30 minutes to obtain an ultrasonic liquid. Take the ultrasonic liquid and add sodium borohydride ethanol solution with a concentration of 0.14mol / L according to the mass ratio of 7~9:4~6, stir and mix at 25~30°C for 1~2h, attract with a magnet, take the magnetic attractant a and wash it with deionized water , washed with ethanol, and dried to obtain a nano-copper-based catalyst.

Embodiment 1

[0032]Catalyst active body: (1) Take dimethylimidazole and add methanol at a mass ratio of 1:10, stir and mix for 15 minutes to obtain solution A, take cobalt nitrate hexahydrate and add methanol at a mass ratio of 2:25, stir and mix for 10 minutes to obtain solution B , take solution A and add solution B at a mass ratio of 4:2, stir and mix at 45°C for 20 minutes, let it stand for 36 hours, centrifuge, take the precipitate, wash it with methanol, and dry it to obtain a dried product, take the dried product and keep it warm at 400°C for 2 hours, and control the temperature rise The rate was 2°C / min, and cooled to room temperature to obtain a cooled product;

[0033] (2) Take the cooling material and add ethanol at a mass ratio of 1:50, stir and mix for 5 minutes, then add 7% copper nitrate hexahydrate of the cooling material, stir and mix for 2 hours, centrifuge, take the precipitate a, wash it with absolute ethanol, dry it, and Calcined at 350°C for 1 hour and cooled to room ...

Embodiment 2

[0039] Catalyst active body: (1) Take dimethylimidazole and add methanol at a mass ratio of 2:15, stir and mix for 18 minutes to obtain solution A, take cobalt nitrate hexahydrate and add methanol at a mass ratio of 3:30, stir and mix for 15 minutes to obtain solution B , take solution A and add solution B according to the mass ratio of 6:3, stir and mix at 47°C for 25min, let it stand for 50h, centrifuge, take the precipitate, wash with methanol, and dry to obtain a dry product, take the dry product and keep it at 430°C for 2.5h, control The heating rate was 2°C / min, and cooled to room temperature to obtain a cooled product;

[0040] (2) Take the cooling material and add ethanol according to the mass ratio of 3:55, stir and mix for 7 minutes, then add 9% copper nitrate hexahydrate of the cooling material, stir and mix for 2.5 hours, centrifuge, take the precipitate a, wash it with absolute ethanol, and dry it. Calcined at 370°C for 1.5h and cooled to room temperature to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com