Method for reducing molecular weight of starch through dry method

A technology of molecular weight and starch, which is applied in the field of dry method to reduce the molecular weight of starch, can solve the problems of large production water consumption, high drying energy consumption, environmental pollution, etc., and achieve the effect of no need for washing, no reagent residue, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

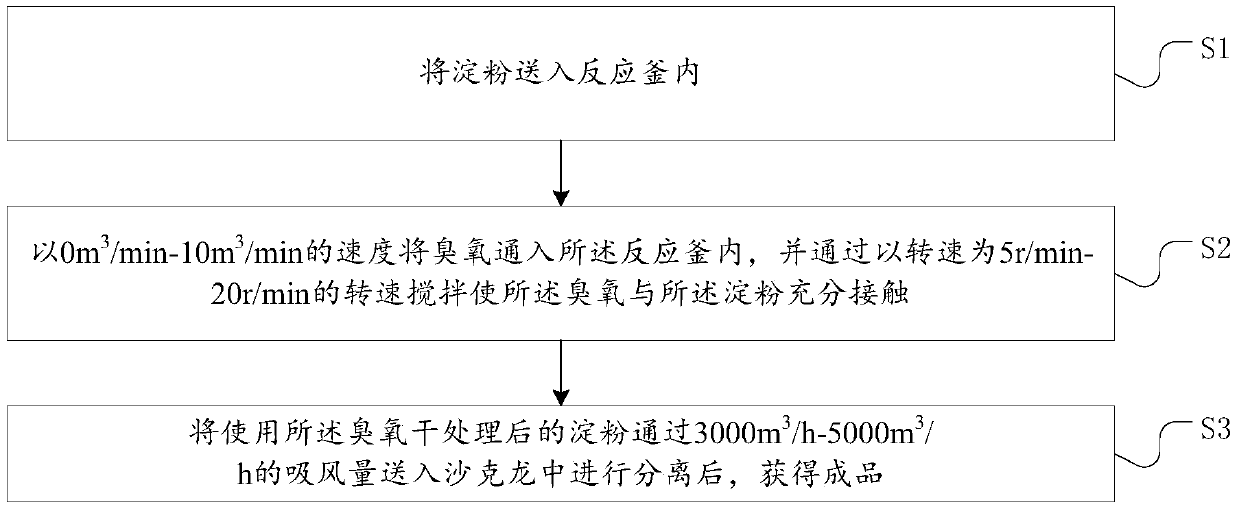

Method used

Image

Examples

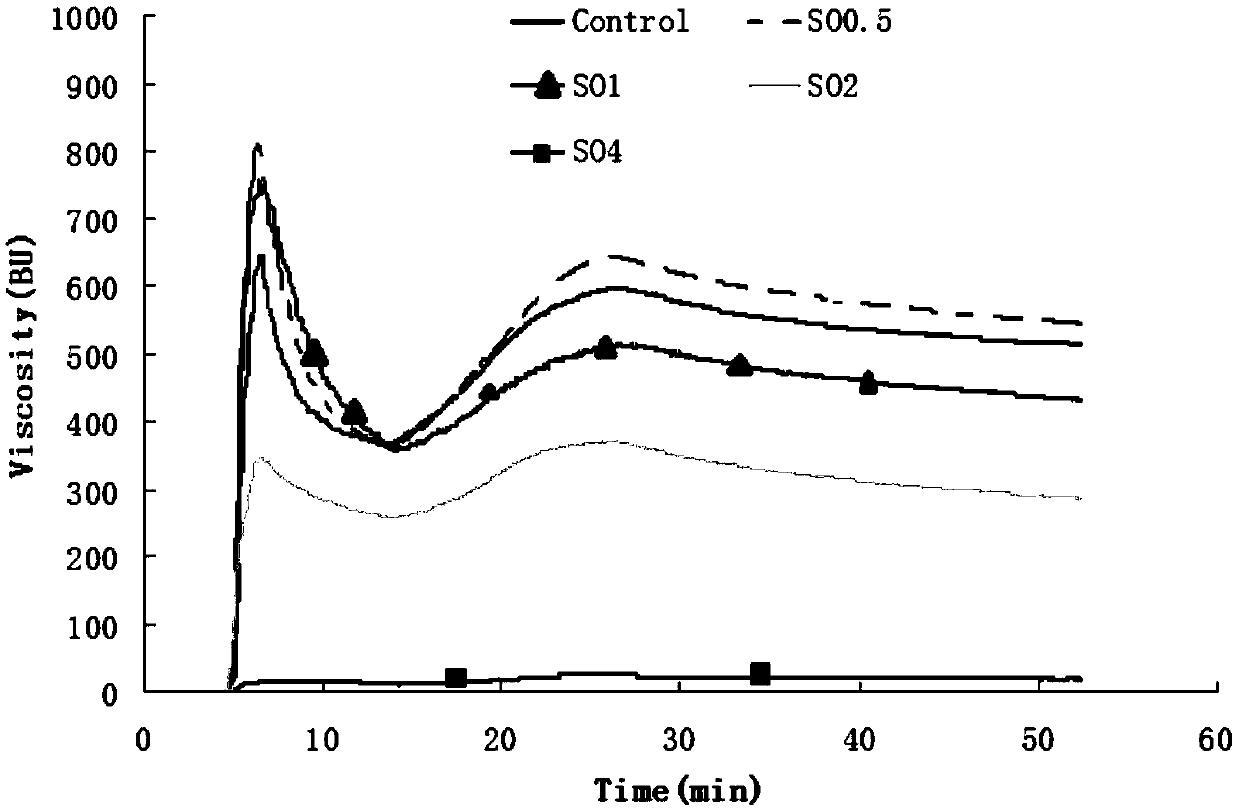

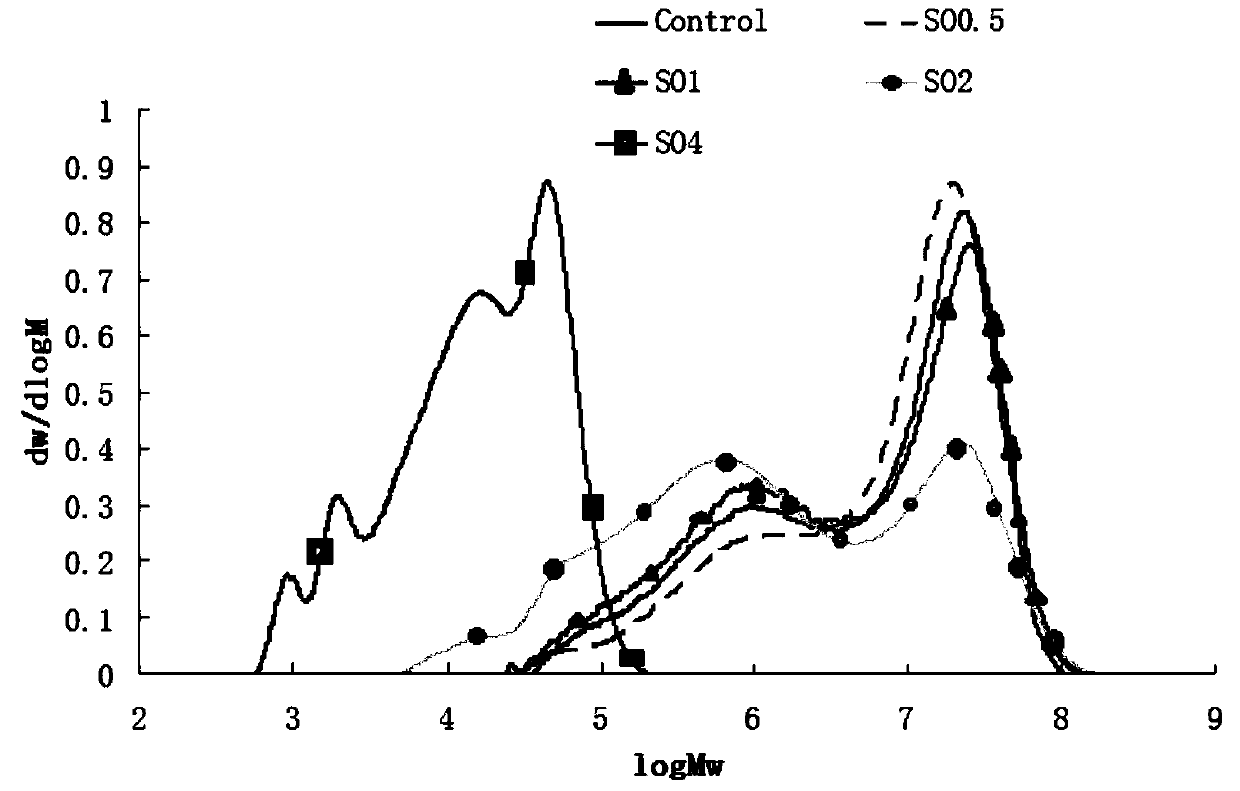

Embodiment 1

[0044] The invention provides a kind of preparation method that dry method reduces the molecular weight of glutinous rice starch, and concrete process step of the present invention is as follows:

[0045] 1. Raw material selection: glutinous rice starch with a purity of more than 90% and a moisture content of less than 14%;

[0046] 2. Oxidation process: Add 20kg of glutinous rice starch to the oxidation reaction kettle, with the ozone concentration at 10mg / L, press 5m 3Ozone is input from the inner wall of the reactor to the bottom at a speed of 10r / min, and the ozone is fully contacted with the glutinous rice starch by stirring at a speed of 10r / min, so that the ozone and the glutinous rice starch are fully contacted to ensure the uniformity of the oxidation reaction. The reaction process lasted for 1 hour respectively, and the reaction temperature was kept at 30° C. through the jacket of the reaction tank;

[0047] 3. Sample collection: The glutinous rice starch after ozon...

Embodiment 2

[0050] The invention provides a kind of preparation method that dry method reduces the molecular weight of glutinous rice starch, and concrete process step of the present invention is as follows:

[0051] 1. Raw material selection: glutinous rice starch with a purity of more than 90% and a moisture content of less than 14%.

[0052] 2. Oxidation process: Add 20kg of glutinous rice starch to the oxidation reaction kettle, with the ozone concentration at 10mg / L, press 5m 3 Ozone is input from the inner wall of the reactor to the bottom at a speed of 10r / min, and the ozone is fully contacted with the glutinous rice starch by stirring at a speed of 10r / min, so that the ozone and the glutinous rice starch are fully contacted to ensure the uniformity of the oxidation reaction. The reaction process lasted for 2 hours respectively, and the reaction temperature was kept at 30° C. through the jacket of the reaction tank.

[0053] 3. Sample collection: The glutinous rice starch after oz...

Embodiment 3

[0056] The invention provides a kind of preparation method that dry method reduces the molecular weight of glutinous rice starch, and concrete process step of the present invention is as follows:

[0057] 1. Raw material selection: glutinous rice starch with a purity of more than 90% and a moisture content of less than 14%.

[0058] 2. Oxidation process: Add 20kg of glutinous rice starch to the oxidation reaction kettle, with the ozone concentration at 10mg / L, press 5m 3 Ozone is input from the inner wall of the reactor to the bottom at a speed of 10r / min, and the ozone is fully contacted with the glutinous rice starch by stirring at a speed of 10r / min, so that the ozone and the glutinous rice starch are fully contacted to ensure the uniformity of the oxidation reaction. The reaction process lasted for 4 hours respectively, and the reaction temperature was kept at 30° C. through the jacket of the reaction tank.

[0059] 3. Sample collection: The glutinous rice starch after oz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com