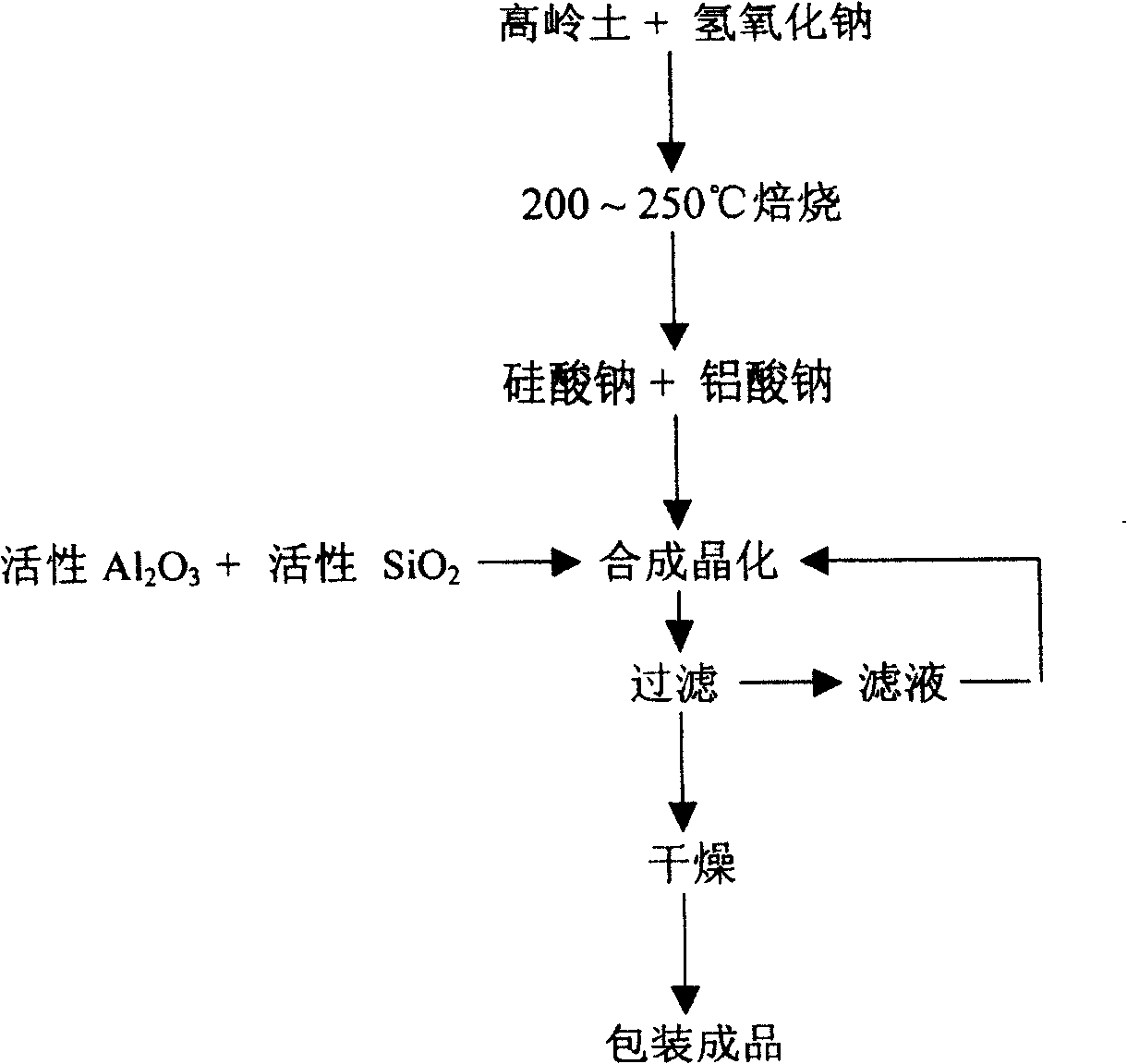

4A zeolite synthesized from kaolin by low-temperature alkali fusion method

A technology of kaolin and alkali fusion method, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of high cost and cumbersome process, and achieve low cost, simplified process flow and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

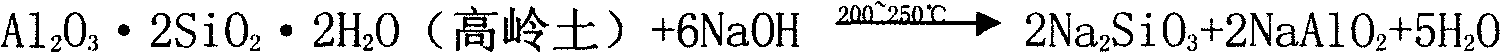

[0025] Mix 25.8g of kaolin and 24.0g of sodium hydroxide evenly, add 30ml of water to make the mixture thick, roast at 200°C for 2 hours, pour it into a flask after cooling, and heat for 1 hour, 20.4g of active aluminum oxide, 24g Active silicon dioxide is mixed evenly, and added evenly within 1 hour, and 162ml of water is added to stir and crystallize for 1 hour. Heating on a water bath at a constant temperature of 95°C for 3 hours, suction filtration, and then drying at 110°C for 2 hours to obtain 4A zeolite product. The product has been tested by "X-ray diffraction analysis", and the 4A zeolite content is above 96%, and its calcium exchange rate is about 310mg CaCO 3 / g, all physical and chemical indicators have reached or exceeded the national standard.

Embodiment 2

[0027] Mix 25.8g of kaolin and 25.6g of sodium hydroxide evenly, add 50ml of water to make the mixture thick, roast at 250°C for 2 hours, pour it into a flask after cooling, 20.4g of active aluminum oxide, 24g of active silicon dioxide Mix evenly, add evenly within 1 hour, add 162ml of water, stir and crystallize for 1 hour. Heating on a water bath at a constant temperature of 90°C for 4 hours, suction filtration, and drying at 105°C for 2 hours to obtain 4A zeolite product. The product has been tested by "X-ray diffraction analysis", and the 4A zeolite content is above 98%, and its calcium exchange rate is about 327mg CaCO 3 / g, all physical and chemical indicators have reached or exceeded the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com